450g Ozone Generator

Highly efficient and energy-saving, ozone utilization rate is as high as 95%

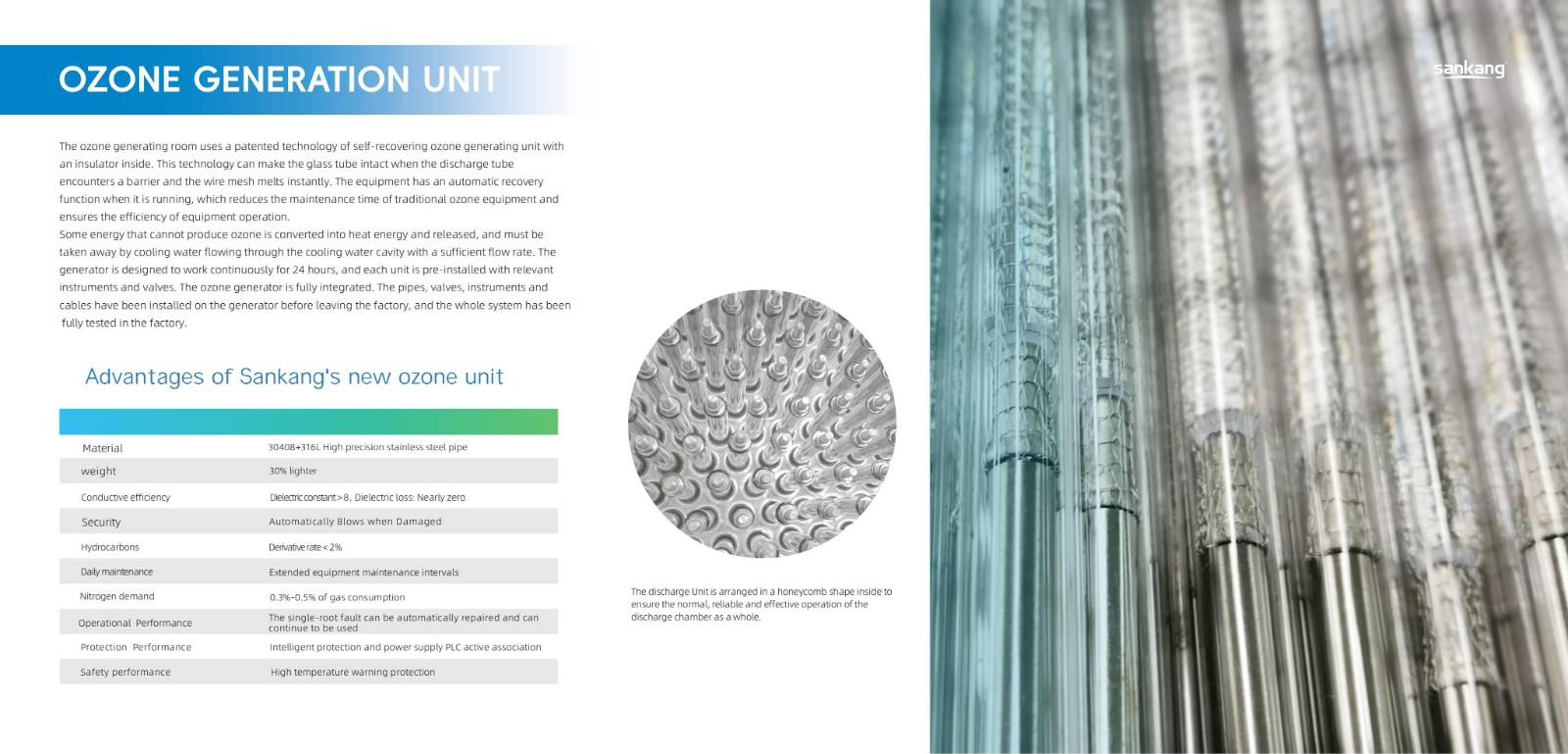

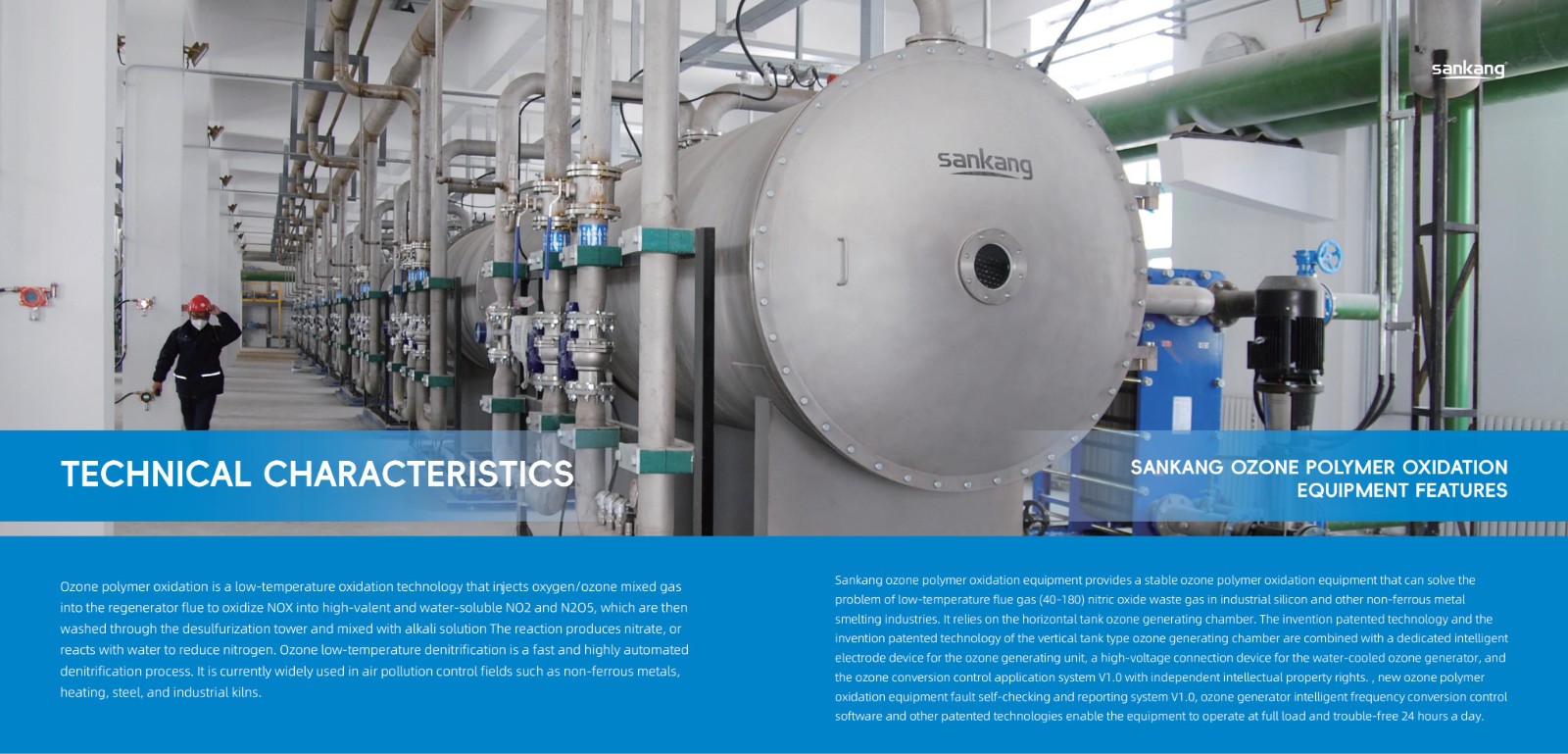

The application of IGBT inverter medium-frequency high-voltage power supply can effectively improve ozone generation efficiency, achieve high efficiency and energy saving, and ensure continuous and stable operation.

The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.

The ozone system uses water cooling technology to maintain efficient and stable ozone production.

The discharge tube adopts advanced high borosilicate tube discharge technology.

Today, as modern technology and environmental protection concepts are increasingly integrated, ozone generators, as an efficient and environmentally friendly air purification equipment, are widely used in water treatment, air purification, food processing, medical and health care and other fields. Among them, the 450g ozone generator has become a highly anticipated product in the market with its powerful ozone production capacity and wide range of applications. This article will explore the working principle, performance characteristics, application fields and precautions of the 450g ozone generator in depth, in order to provide readers with a comprehensive and in-depth understanding.

1. Working principle and technical basis

As the name suggests, the 450g ozone generator is designed to produce 450 grams of ozone per hour. Ozone (O₃) is a molecule composed of three oxygen atoms. Compared with common diatomic oxygen (O₂), ozone has stronger oxidizing and bactericidal abilities. The ozone generator decomposes oxygen molecules (O₂) in the air into single oxygen atoms (O) through high-voltage discharge or ultraviolet irradiation, and then these oxygen atoms combine with undecomposed oxygen molecules to form ozone (O₃).

450g ozone generators usually use high-frequency and high-voltage discharge technology, that is, high-frequency alternating current is used to generate a high-voltage electric field in a special discharge tube, so that the oxygen molecules in the ionized air passing through are cracked and recombined to generate ozone. In this process, the design of the discharge tube, the stability of the power supply, and the efficiency of the cooling system are all key factors affecting the ozone production. In addition, the advanced control system can accurately adjust the discharge intensity and working time to ensure the stability and efficiency of ozone generation.

2. Performance characteristics and advantages

1. **High-efficiency production capacity**: The ozone output of 450g means that the equipment can quickly produce a large amount of ozone in a short time, meeting the application scenarios of large-scale space or high-concentration ozone demand.

2. **Energy saving and environmental protection**: The ozone generator does not need to add any chemical agents during operation, only consumes electricity, and the ozone will naturally decompose into oxygen after completing the task, and will not cause secondary pollution to the environment.

3. **Broad-spectrum sterilization**: Ozone has extremely strong oxidizing properties, can effectively kill bacteria, viruses, molds and other microorganisms, and will not produce drug resistance. It is an ideal natural disinfectant.

4. **Purify air and water**: In addition to sterilization and disinfection, ozone can also effectively remove odors, formaldehyde and other harmful gases in the air, as well as organic matter, heavy metals and other pollutants in water, improving water and air quality.

5. **Intelligent control**: Modern 450g ozone generators are generally equipped with intelligent control systems, which can set working modes according to actual needs, such as timed start, automatic adjustment of ozone concentration, etc., which are easy to operate, safe and reliable.