10KG/h Ozone Generator For Semiconductor Cleaning

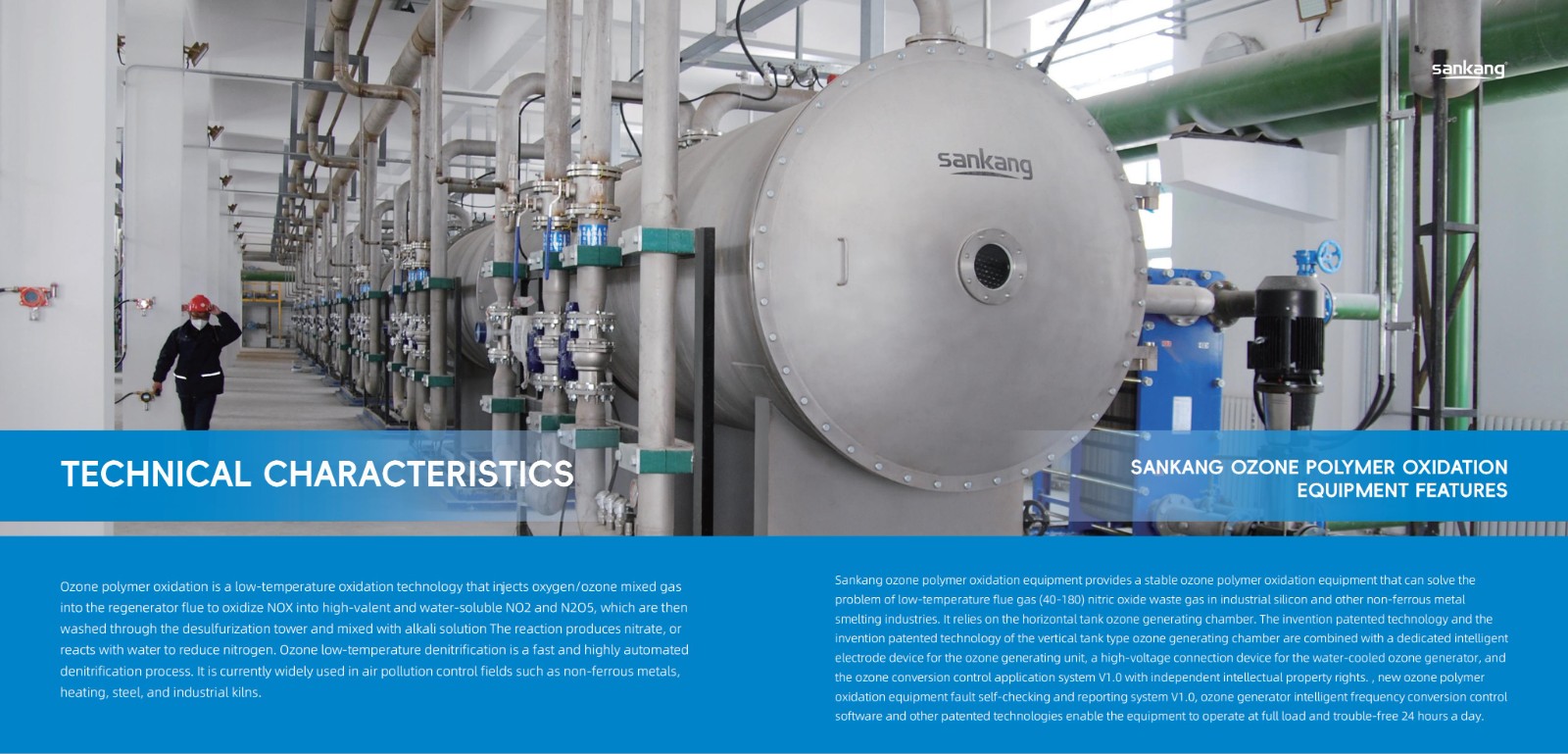

The research and development of this equipment aims to solve the problems of excessive local temperature during operation of traditional ozone equipment, inaccurate ozone production, inability to automatically adjust, and unsafe, uneconomical, and impractical equipment operation. This equipment can also realize automatic adjustment of ozone polymer output and ozone concentration according to the level of nitrogen oxides in the exhaust gas, effectively avoiding excessive problems caused by nitrogen oxide fluctuations, and effectively saving costs under low nitrogen oxide conditions. This equipment provides an efficient, collaborative, easy-to-install, cost-optimized denitrification equipment for the non-ferrous metal smelting industry under low-temperature flue gas (40-180°C) conditions. Currently, this equipment has been widely promoted and used.

In modern semiconductor manufacturing, the cleaning process is crucial. Semiconductor materials are extremely sensitive to tiny impurities and contaminants, and any tiny contamination may cause equipment performance degradation or failure. In order to meet this high standard, it is particularly important to adopt efficient cleaning technology. Among them, ozone generators, as an efficient and environmentally friendly cleaning equipment, play a key role in semiconductor production. This article will introduce in detail a 10KG/H (i.e., 10 kilograms of ozone per hour) ozone generator, its application in semiconductor cleaning and its advantages.

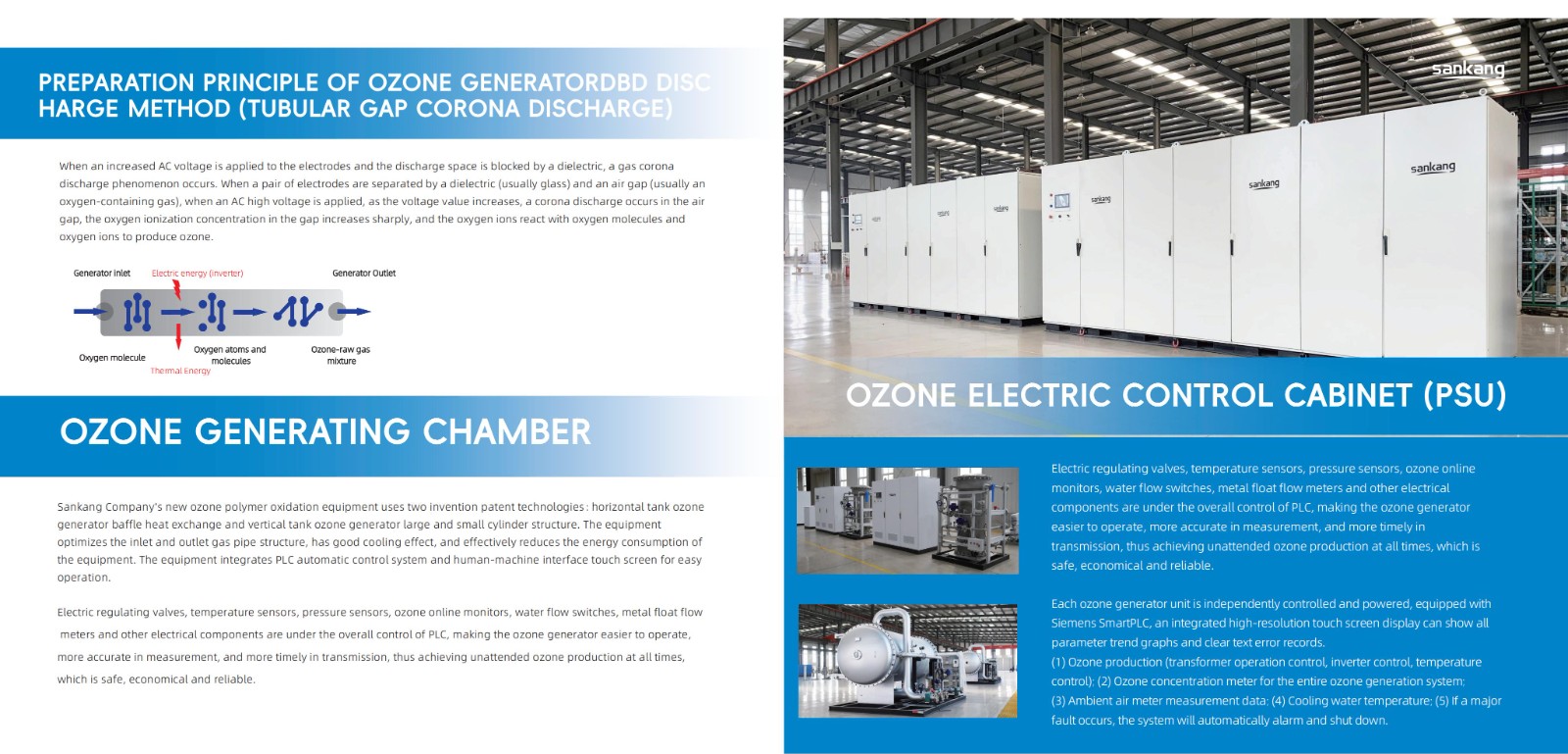

1. The basic principle of ozone generator

Ozone (O3) is a molecule composed of three oxygen atoms and has strong oxidizing properties. It can quickly decompose organic matter, kill bacteria and viruses through oxidation, and can effectively remove various pollutants on the surface. The ozone generator decomposes oxygen (O2) molecules in the air into single oxygen atoms through high-voltage discharge or ultraviolet rays, and then these oxygen atoms combine with undecomposed oxygen molecules to form ozone molecules. This process usually needs to be carried out under specific conditions, including suitable temperature, humidity and air flow rate.

2. Design features of 10KG/H ozone generator

1. High efficiency and stability

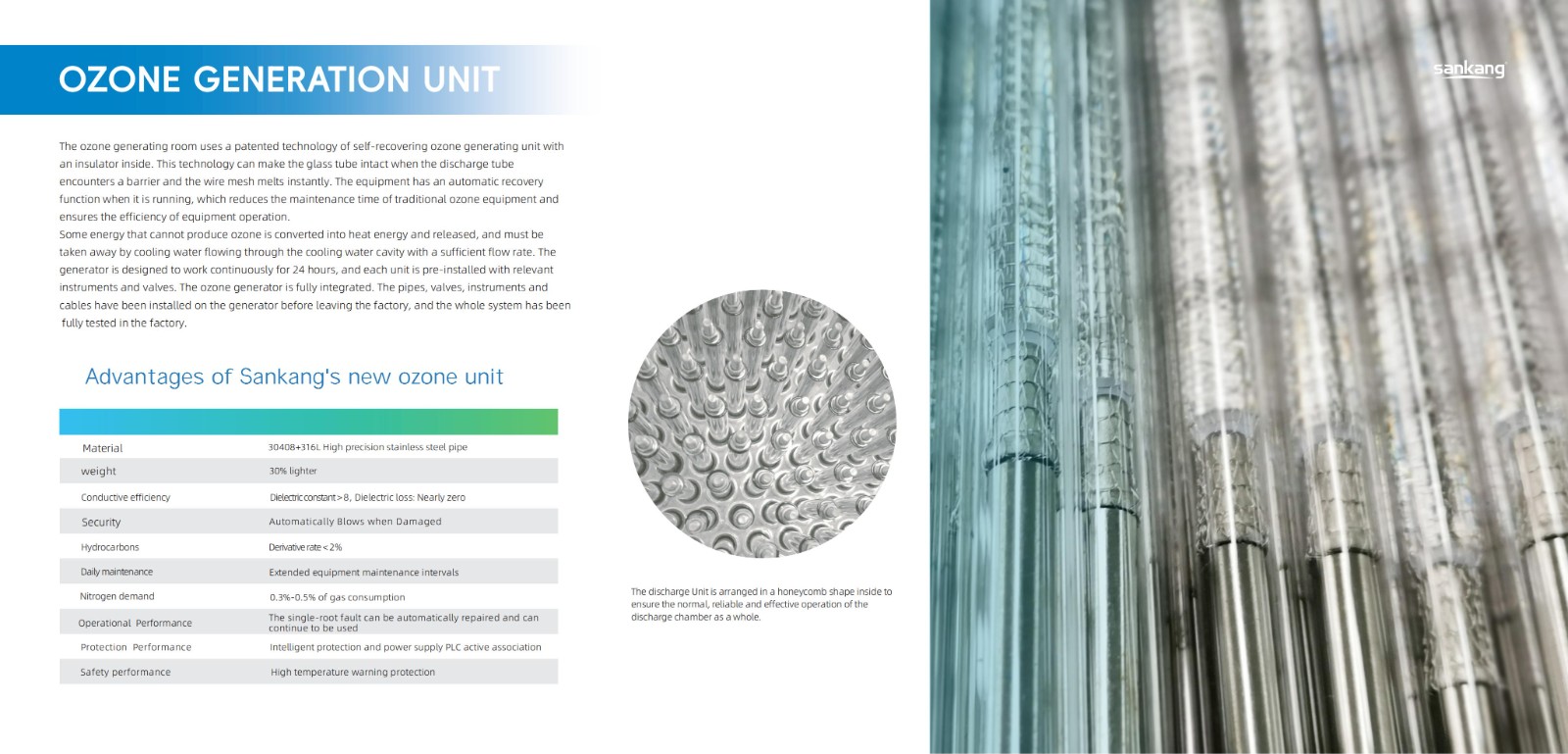

This 10KG/H ozone generator adopts advanced ozone generation technology to ensure that high-quality ozone can be stably produced under continuous working conditions. Its internal structure is reasonably designed and the air flow channel is optimized, which makes the ozone generation efficiency extremely high while reducing energy consumption. In addition, the equipment has a built-in intelligent control system that can automatically adjust the ozone output according to actual needs to ensure the stability and reliability of the cleaning process.

2. Safety protection measures

Although ozone has a strong cleaning ability, it is also a toxic gas that needs to be properly handled. This ozone generator is designed with full consideration of safety and is equipped with multiple safety protection measures. For example, an ozone leak detection sensor is installed inside the device. Once the ozone concentration is detected to be excessive, the alarm system will be immediately activated and the power will be automatically cut off. At the same time, the equipment is also equipped with explosion-proof devices and emergency stop buttons to ensure that measures can be taken quickly in an emergency to ensure the safety of personnel and equipment.

3. Easy maintenance and operation

In order to reduce operating costs and improve the efficiency of equipment use, this ozone generator is designed with ease of use and maintainability in mind. The operating interface of the equipment is simple and clear, and users only need simple training to master the operation method. At the same time, the internal structure of the equipment is reasonably designed to facilitate daily maintenance and overhaul. For example, the core component of the ozone generator, the ozone generating tube, adopts a modular design, which is easy to disassemble and replace, greatly shortening the maintenance time.

III. Application of 10KG/H ozone generator in semiconductor cleaning

In semiconductor production, the cleaning process runs through the entire process, from raw material processing to finished product packaging, and strict cleaning control is required in each link. 10KG/H ozone generators have been widely used in semiconductor cleaning for their high efficiency and environmental protection.

1. Raw material cleaning

Before semiconductor raw materials enter the production line, they need to be strictly cleaned to remove surface pollutants such as oil and dust. The ozone generator can be used with a cleaning fluid to accelerate the decomposition and removal of pollutants through oxidation, thereby improving cleaning efficiency and quality.

2. Production environment purification

The semiconductor production environment has extremely high requirements for cleanliness, and any tiny pollutants may affect product quality. The ozone generator can regularly disinfect the production environment with ozone, effectively remove bacteria, viruses and other microorganisms and organic pollutants in the air, and maintain the cleanliness of the production environment.

3. Equipment surface cleaning

The surface of semiconductor production equipment is prone to dust and pollutants, which may enter the product during the operation of the equipment and cause defects. Using an ozone generator to clean the surface of the equipment can quickly remove pollutants without damaging the surface of the equipment.