122KG/h Ozone Generator

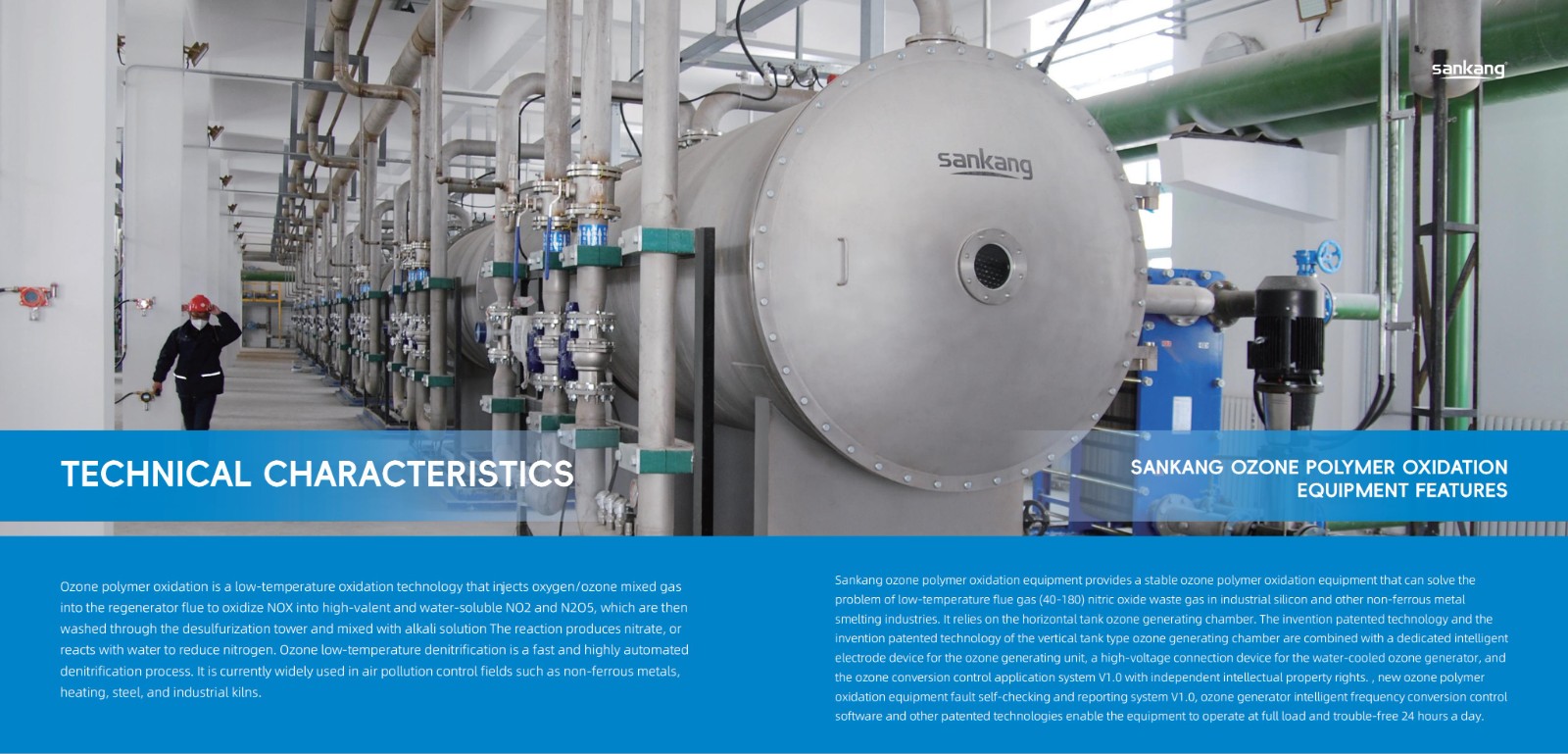

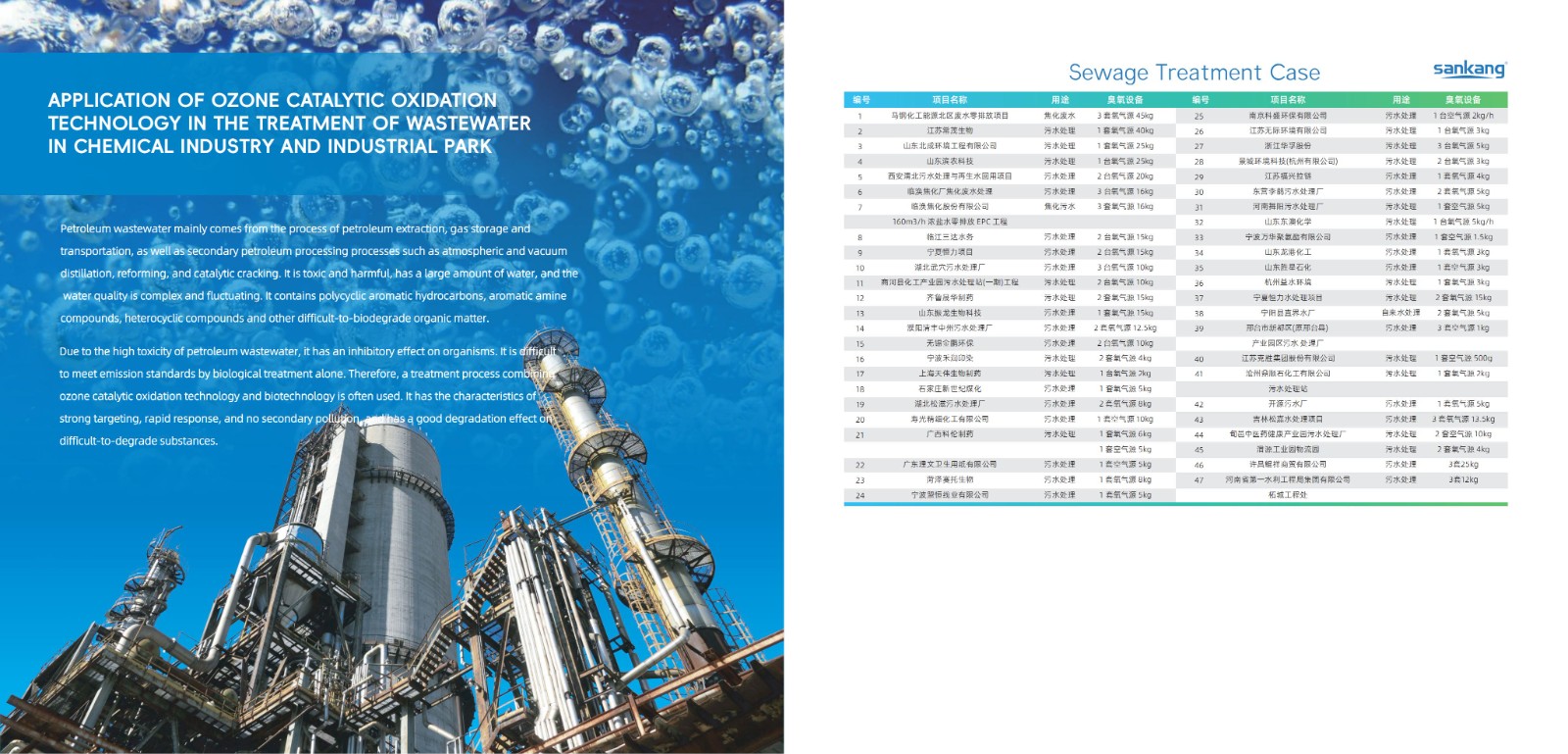

Ozonated polymer oxidation is a low-temperature oxidation technology in which an oxygen/ozone mixture is injected into the regenerator flue to oxidize NOX to the highly valent and water-soluble NO2 and N2O5, which are then scrubbed through the desulfurization tower and reacted with a base solution to form nitrate, or reacted with water to reduce nitrogen gas. Ozone low-temperature denitrification is a fast and highly automated denitrification process. Currently it is widely used in non-ferrous metals, heat, steel, industrial kilns and other air pollution control fields.

As an efficient, safe and environmentally friendly disinfection equipment, ozone generators have been widely used in drinking water treatment, sewage treatment, air purification, chemical oxidation, pulp bleaching, food processing, medical and household fields in recent years. This article will introduce a 120kg/h ozone generator in detail, covering its working principle, technical parameters, scope of application and advantages of use.

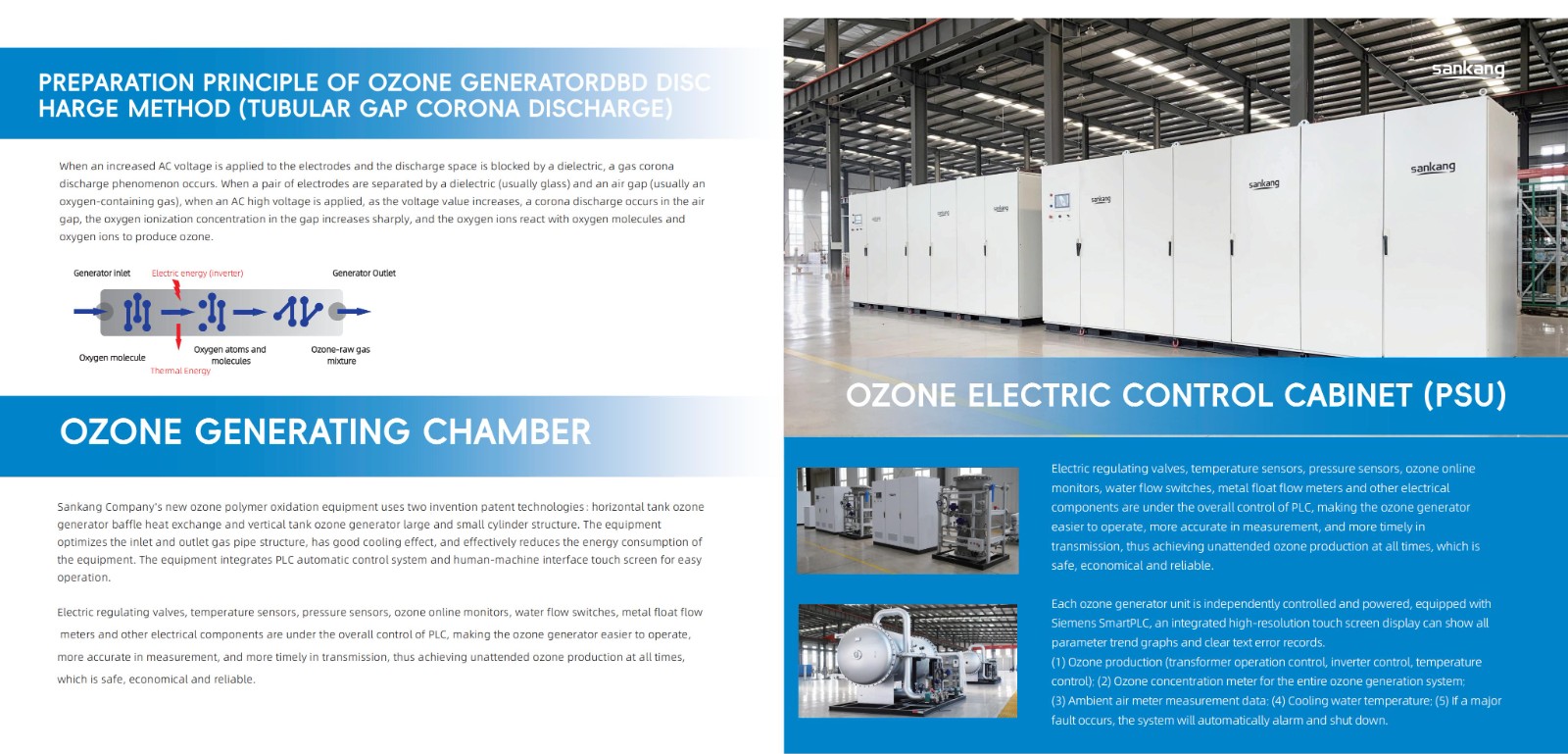

1. Working principle

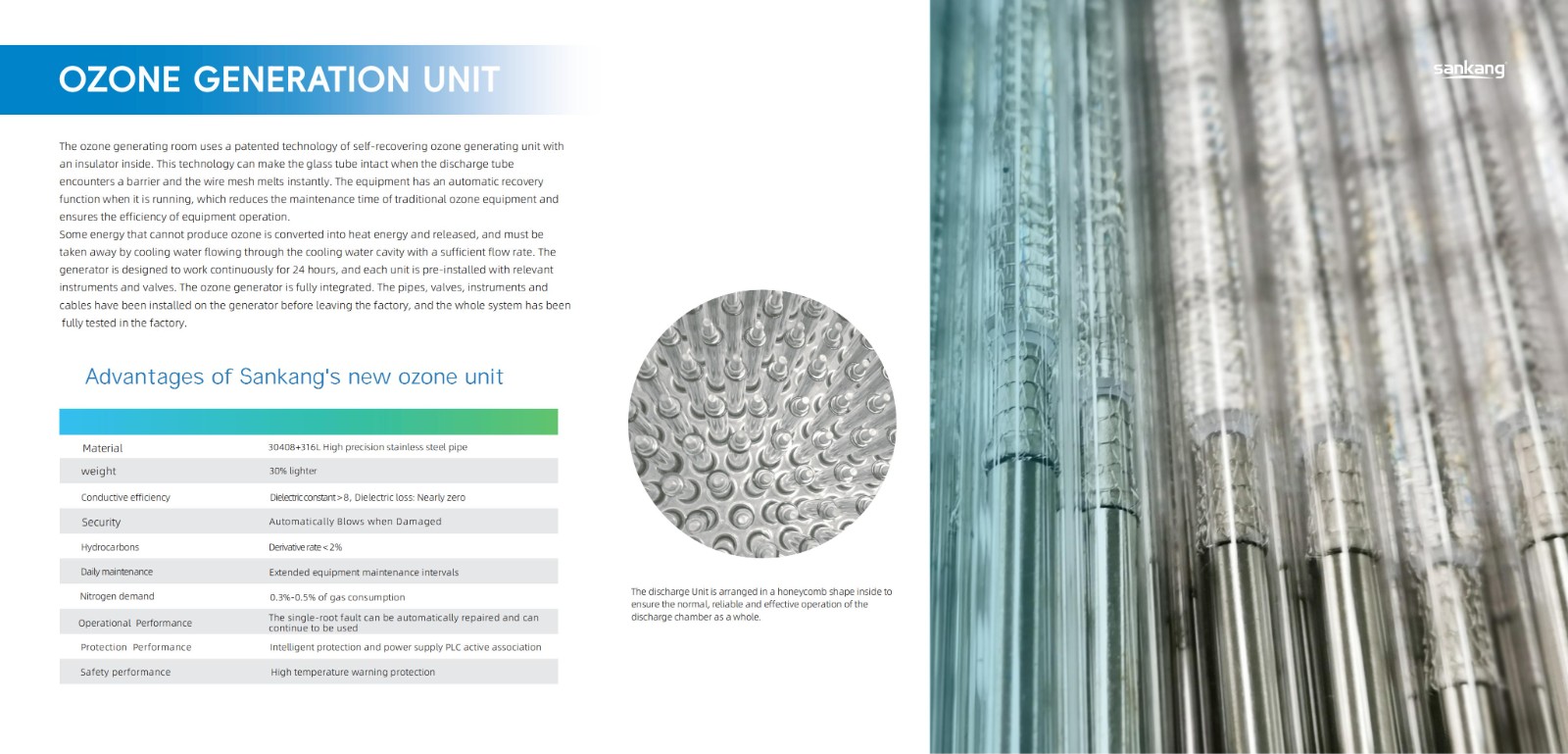

The working principle of the ozone generator is based on the formation principle of ozone, that is, the discharge effect generated by a high-frequency and high-voltage power supply ionizes oxygen or air molecules to generate ozone. Specifically, the ozone generator circuit usually consists of a push-pull oscillation circuit composed of components such as a triode, an inductor coil, a pulse transformer, a current limiting resistor, a charging capacitor and a bidirectional trigger diode. After the power is turned on, the AC voltage is filtered and rectified and supplied to the push-pull oscillation circuit. At the moment of power on, the triode begins to conduct and cut off, generating high-frequency and high-voltage pulses to make the ozone generator work and generate ozone.

The core technology of the ozone generator lies in the discharge tube, and its quality and performance directly affect the operating efficiency and reliability of the equipment. High-quality ozone generators usually use advanced discharge technology and materials to ensure efficient and stable production of ozone.

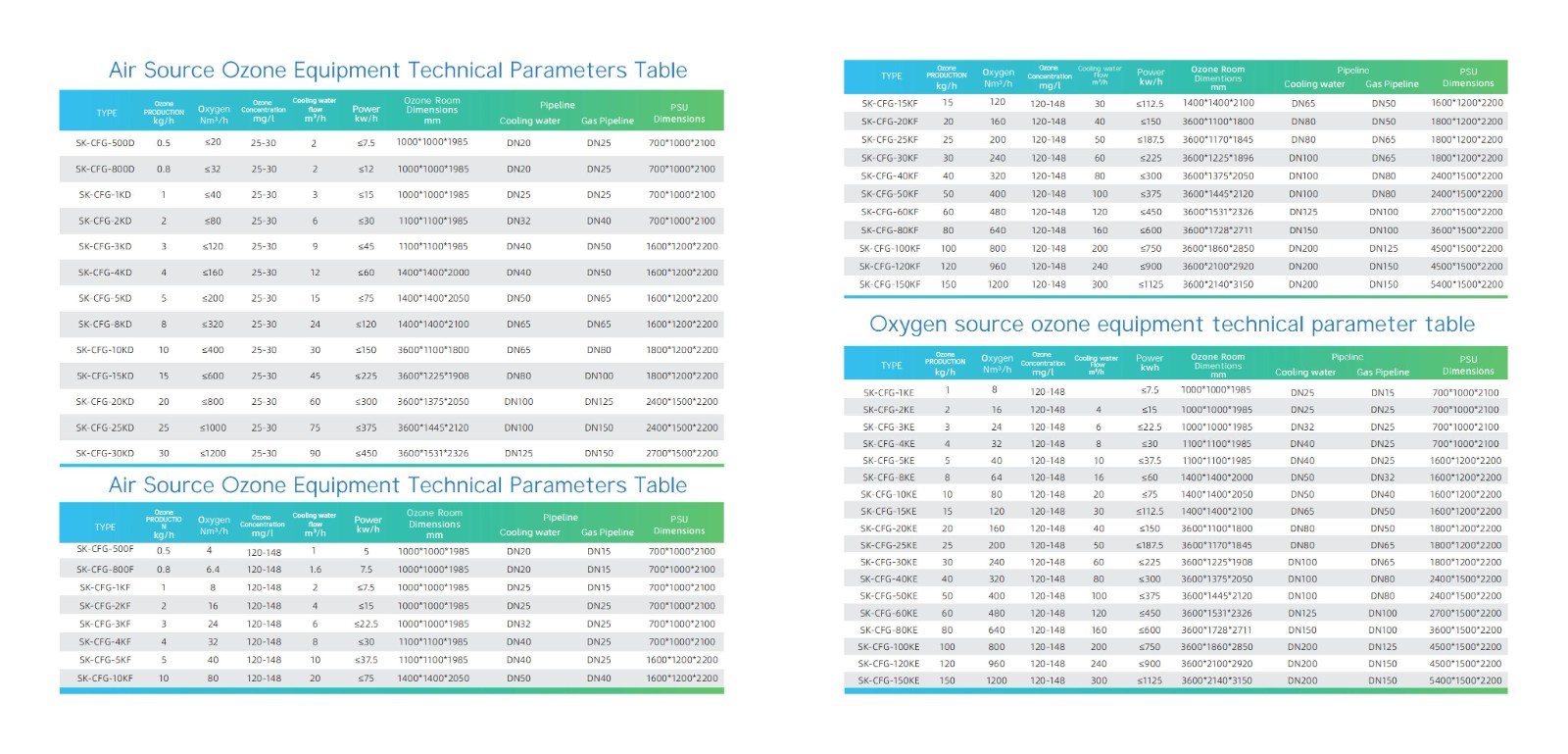

2. Technical parameters

For an ozone generator with a production capacity of 120kg/h, its technical parameters usually include the following aspects:

1. Input power: Usually a three-phase 380V/50Hz power supply is used, allowing a certain voltage fluctuation range.

2. Ozone concentration: Depending on the gas source, the ozone concentration varies. Generally speaking, the ozone concentration of oxygen source can reach 120mg/L to 150mg/L, while the ozone concentration of air source is 20mg/L to 30mg/L.

3. Working voltage and working frequency: The working voltage is usually between thousands of volts and tens of thousands of volts, and the working frequency is between hundreds of hertz and thousands of hertz.

4. Intake flow rate: Depending on the ozone production, the intake flow rate is also different. For an ozone generator with a production capacity of 120kg/h, the intake flow rate is usually between tens and hundreds of cubic meters per hour.

5. Cooling method: Ozone generators are usually cooled by water or air to ensure that the equipment maintains an appropriate temperature during operation.

6. Ozone output: The ozone generator introduced in this article has an output of 120kg/h, which is suitable for large-scale water