125kg Ozone Generator

Highly efficient and energy-saving, ozone utilization rate is as high as 95%

The application of IGBT inverter medium-frequency high-voltage power supply can effectively improve ozone generation efficiency, achieve high efficiency and energy saving, and ensure continuous and stable operation.

The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.

The ozone system uses water cooling technology to maintain efficient and stable ozone production.

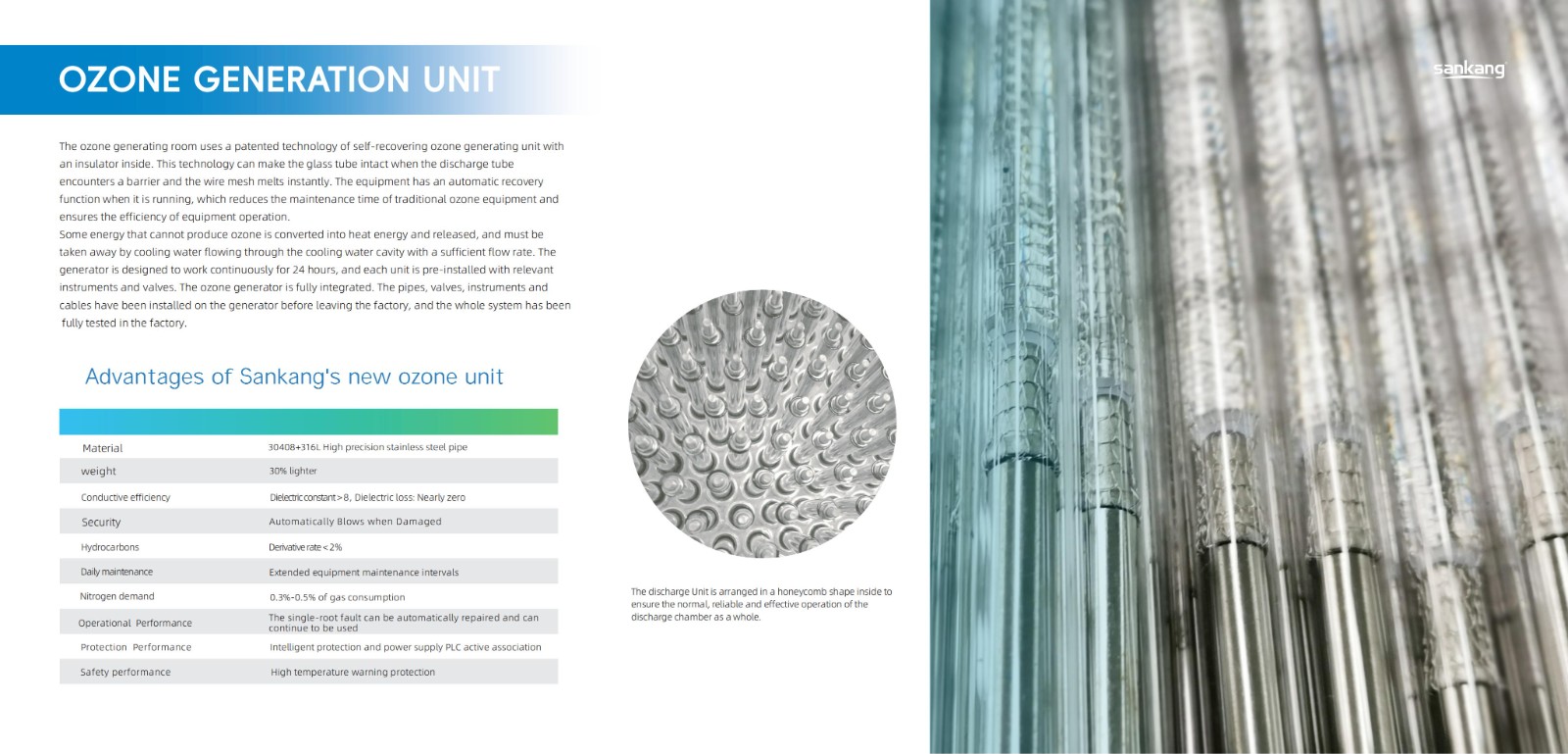

The discharge tube adopts advanced high borosilicate tube discharge technology.

The vacuum thermal regeneration system provides high-quality air to the generating unit and increases the ozone concentration.

The equipment works in negative pressure mode, which effectively avoids ozone leakage and is safe and reliable.

The equipment carries out advanced PLC automatic control and realizes the integration of ozone generation system, air source system, cooling system and control system.

Optimized mechanical design, compact structure, low maintenance workload.

Low harmonic pollution, low power consumption, silent design.

Effective balancing of ejector suction obstruction.

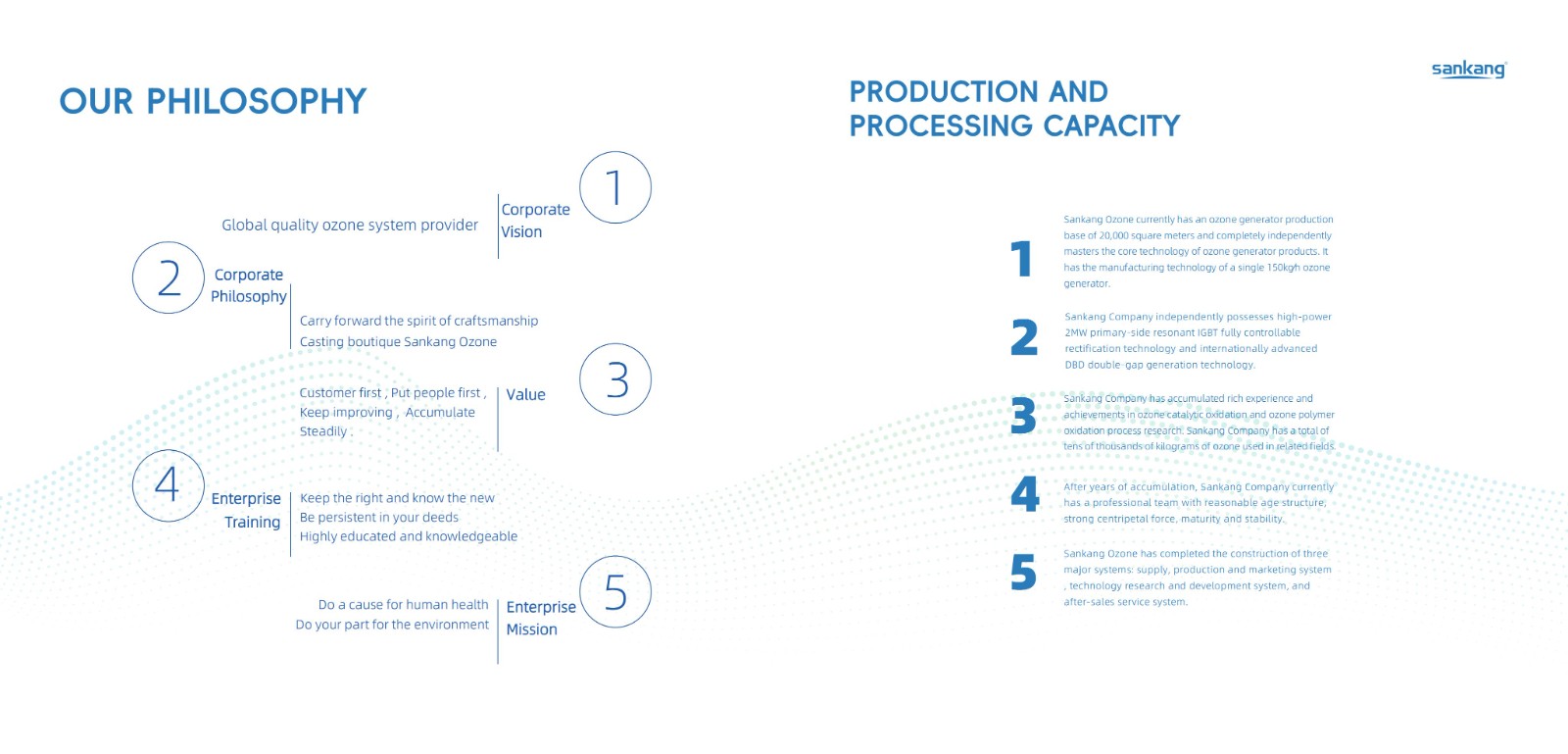

In the field of modern industry and environmental protection, ozone generators, as an efficient and multifunctional equipment, play a vital role. Among them, the 125kg-level ozone generator has become a star product in the market because of its strong production capacity and wide range of applications. This article will deeply explore the technical principles, structural design, application fields, and use and maintenance of the 125kg ozone generator, in order to provide valuable reference for relevant practitioners.

1. Technical Principle

Ozone (O3) is a molecule composed of three oxygen atoms, which has extremely strong oxidizing and sterilizing capabilities. The working principle of the 125kg ozone generator is mainly based on the corona discharge method, that is, the oxygen molecules in the air are ionized by a high-voltage electric field to form ozone. Specifically, the device is equipped with a high-voltage electrode and a grounding electrode. When a sufficiently high voltage is applied between the two electrodes, the oxygen molecules in the air will be accelerated and collided. Some oxygen molecules are cracked into oxygen atoms in the process, and then the oxygen atoms combine with the uncracked oxygen molecules to form ozone molecules. This process is accompanied by a weak discharge sound and a weak blue light, which is a typical phenomenon of ozone generation.

In order to ensure efficient and stable production of ozone, 125kg ozone generators usually use advanced power control systems that can accurately adjust voltage and current to optimize discharge efficiency. At the same time, the equipment is also equipped with an efficient cooling system to ensure that the electrode temperature will not be too high under continuous working conditions, thereby extending the life of the equipment and maintaining the stability of ozone concentration.

2. Structural design

The structural design of the 125kg ozone generator fully considers efficiency, safety and ease of use. The main body of the equipment is usually made of stainless steel or corrosion-resistant alloy to resist the strong oxidizing effect of ozone and ensure long-term stable operation. In terms of internal structure, in addition to the core discharge unit, it also includes multiple modules such as the air intake system, ozone collection and output system, cooling system, and electrical control system.

The air intake system is responsible for introducing clean air or oxygen as raw materials, removing impurities through precision filters to avoid interference with the discharge process. The ozone collection and output system uses the characteristics of ozone being heavier than air, and through a specific pipeline design, the generated ozone is efficiently collected and transported to the target area. The cooling system mostly uses air cooling or water cooling, which automatically adjusts according to the ambient temperature and equipment load to ensure that the equipment is at the optimal working temperature. The electrical control system integrates intelligent management functions such as fault self-detection and remote monitoring, which improves the reliability and ease of use of the equipment.

III. Application Fields

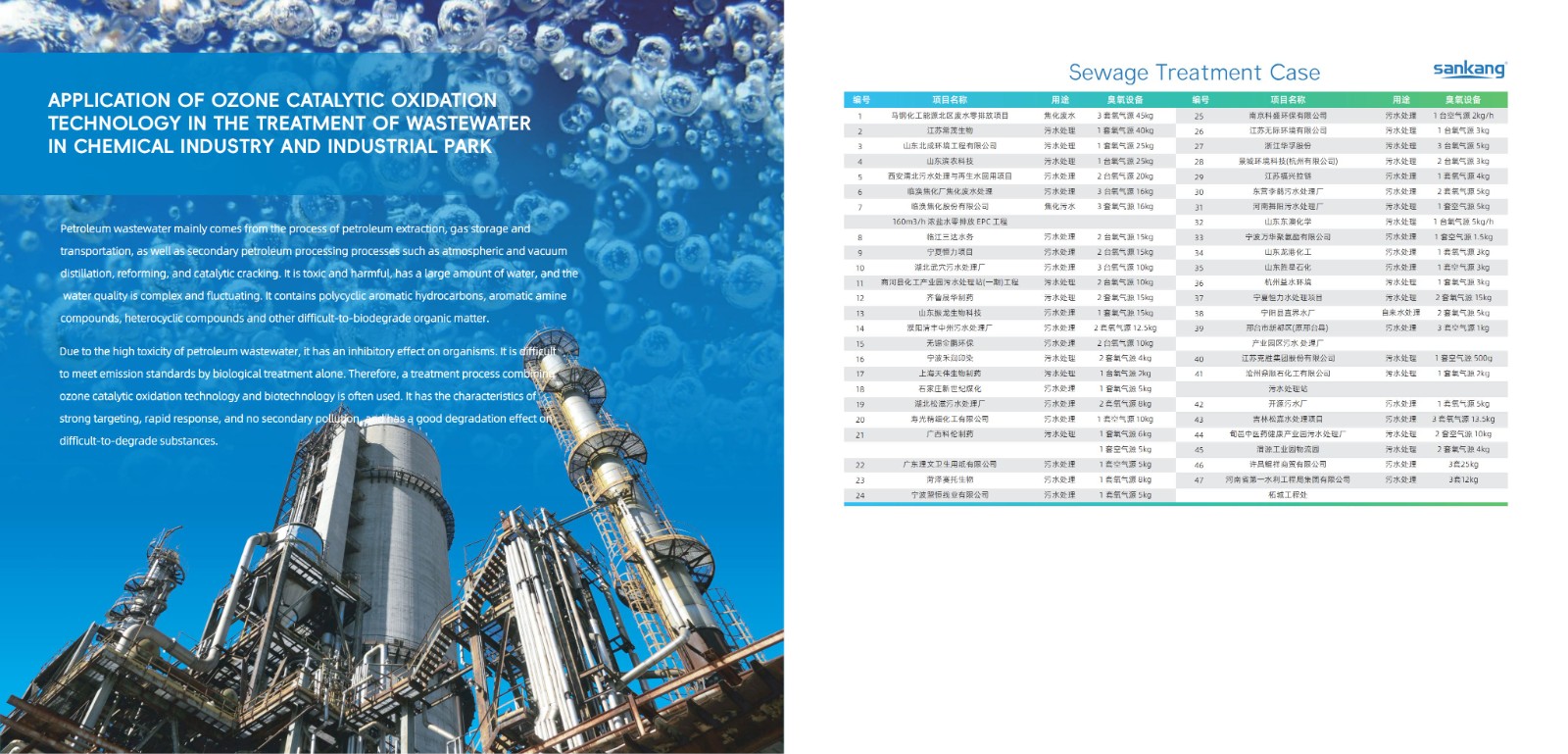

The 125kg ozone generator has shown a wide range of application value in many fields due to its powerful ozone production capacity. In the field of water treatment, it is widely used in swimming pools, drinking water treatment, industrial wastewater purification, etc., effectively killing bacteria, viruses and parasites, removing odor and color, and improving water quality. In terms of air purification, the ozone generator can decompose harmful gases such as formaldehyde and benzene in the air, kill microorganisms in the air, and improve indoor air quality. In addition, in the fields of food preservation, medical disinfection, agricultural pest control, etc., the 125kg ozone generator also plays an irreplaceable role.

IV. Use and Maintenance

The correct use and maintenance of the 125kg ozone generator is essential to ensure its performance and extend its service life. Before operation, you should carefully read the equipment manual to understand the operating procedures and safety precautions. During use, the working status of the power supply, electrodes, cooling system and pipe connections should be checked regularly, and dust and dirt should be cleaned in time to prevent blockage and overheating. After shutdown, the equipment should be completely cooled before cleaning and maintenance to avoid the risk of electric shock or burns.

At the same time, in order to maintain the stability of ozone concentration, it is recommended to regularly test the performance of the ozone generator, including testing of indicators such as ozone production, concentration, and power consumption, and adjust the working parameters or replace aging parts according to the test results. In addition, it is also an effective way to protect equipment and extend its life to arrange the equipment operation time reasonably and avoid long-term continuous work.

In short, as an important equipment in the field of environmental protection, the knowledge of the technical principles, structural design, application fields, and use and maintenance of the 125kg ozone generator is of great significance to improving work efficiency and ensuring production safety. With the continuous advancement of science and technology and the increasing awareness of environmental protection, it is believed that such equipment will play a greater role in more fields and contribute to the construction of a green and healthy living environment.