149KG Ozone Generator

Highly efficient and energy-saving, ozone utilization rate is as high as 95%

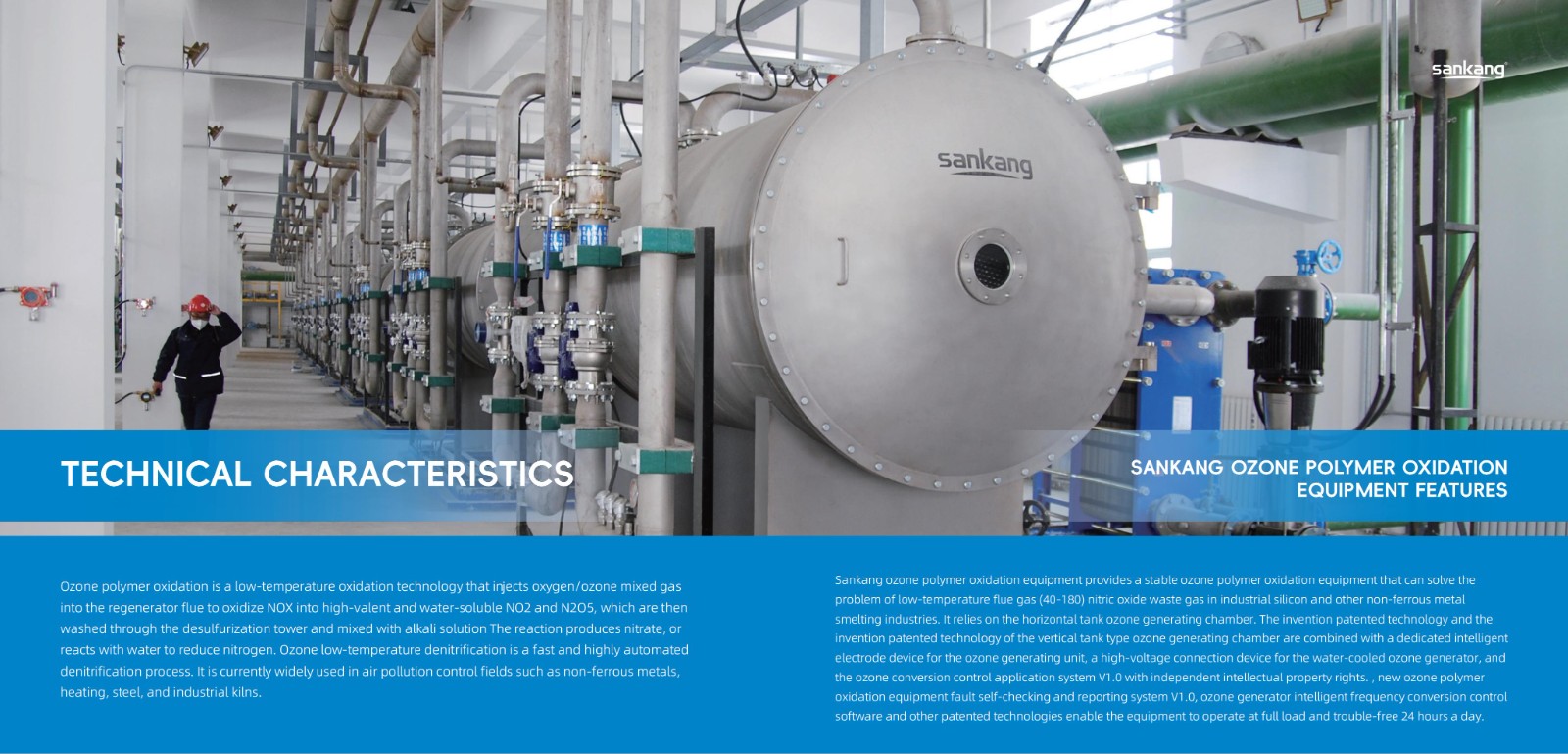

The application of IGBT inverter medium-frequency high-voltage power supply can effectively improve ozone generation efficiency, achieve high efficiency and energy saving, and ensure continuous and stable operation.

The ozone system uses water cooling technology to maintain efficient and stable ozone production.

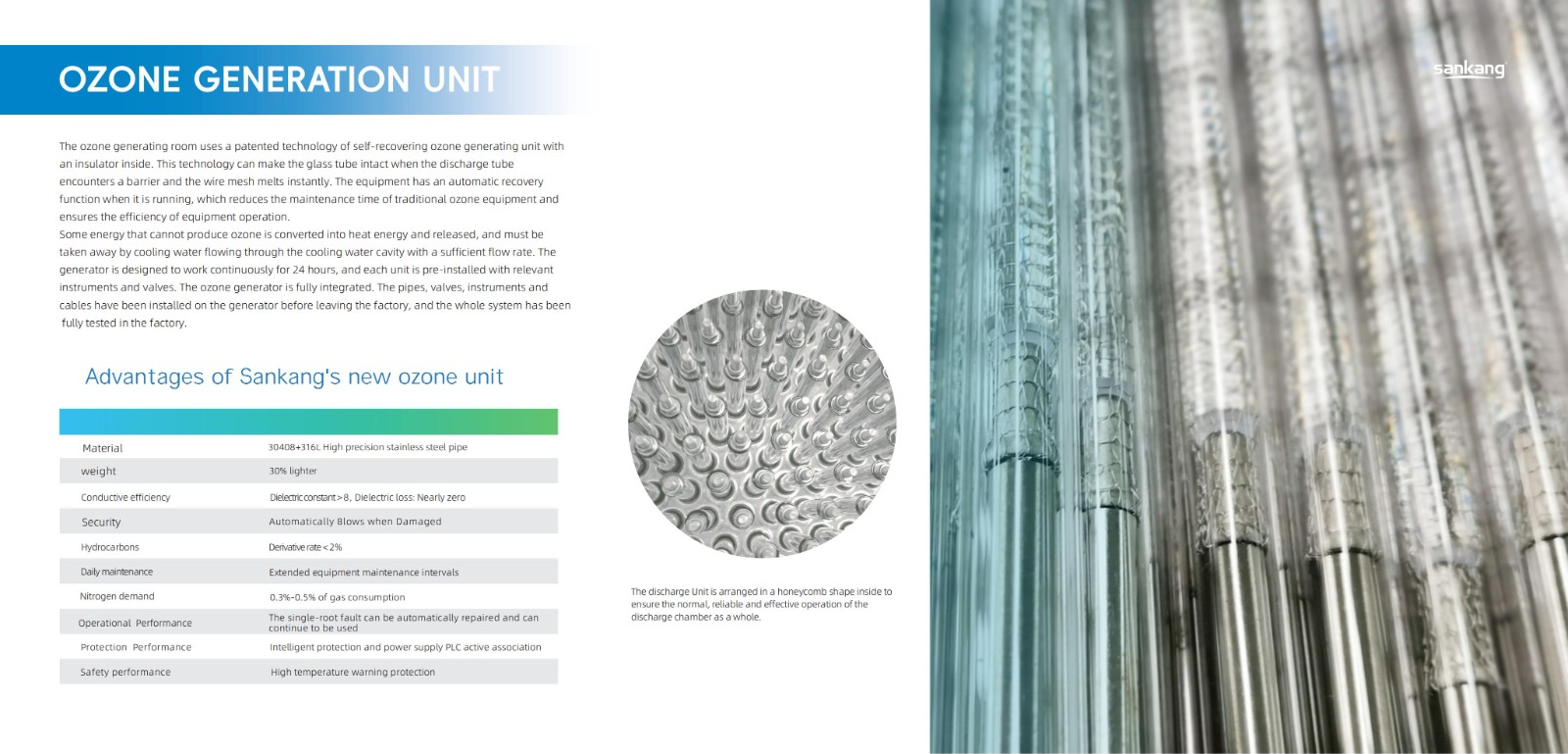

The discharge tube adopts advanced high borosilicate tube discharge technology.

The vacuum thermal regeneration system provides high-quality air to the generating unit and increases the ozone concentration.

The equipment works in negative pressure mode, which effectively avoids ozone leakage and is safe and reliable.

The equipment carries out advanced PLC automatic control and realizes the integration of ozone generation system, air source system, cooling system and control system.

Optimized mechanical design, compact structure, low maintenance workload.

Low harmonic pollution, low power consumption, silent design.

Effective balancing of ejector suction obstruction.

The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.

As an important environmental protection equipment, ozone generator plays an irreplaceable role in many fields. This article will introduce a 150KG ozone generator in detail, including its working principle, application field, technical specifications and precautions for use, in order to provide valuable reference for relevant practitioners.

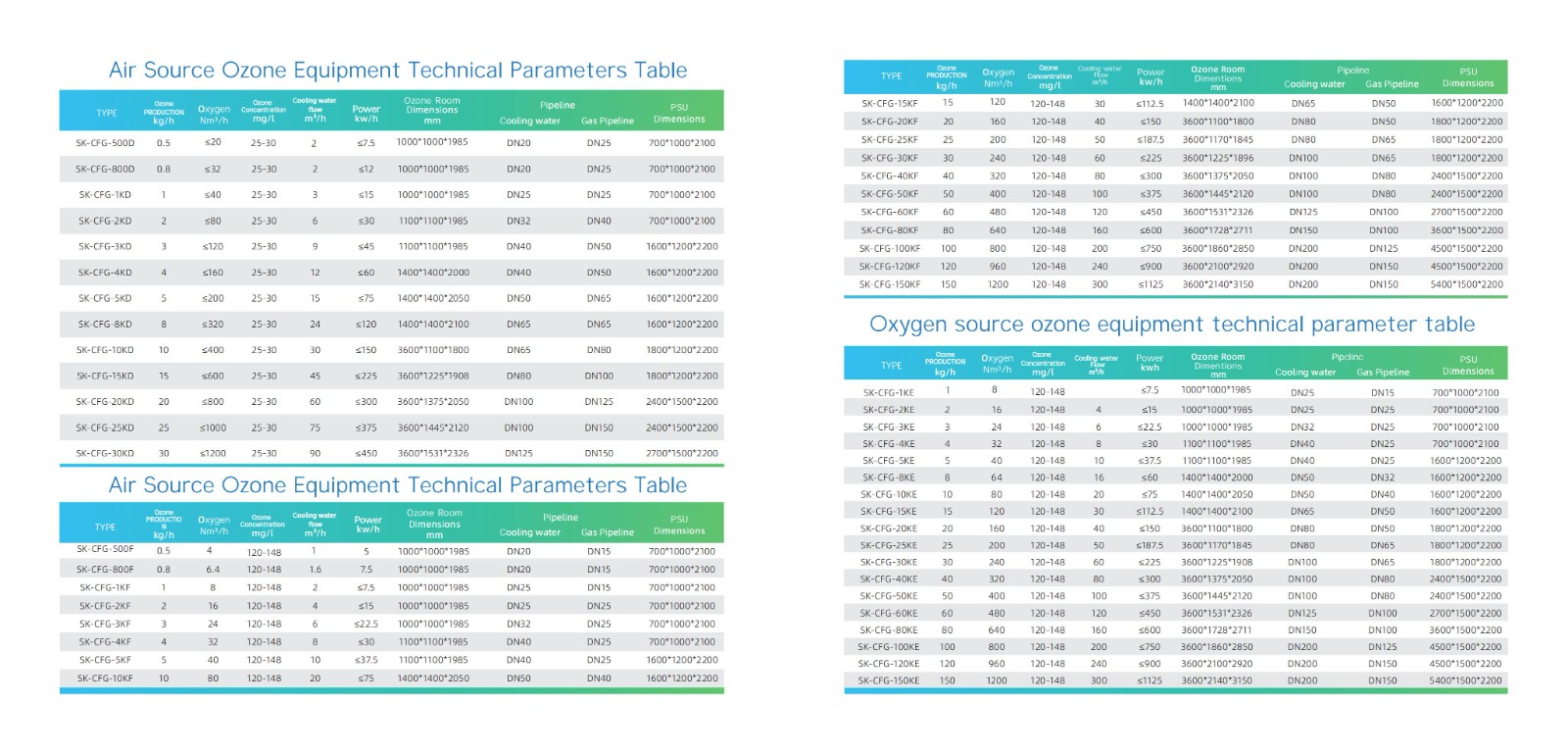

1. Working principle of ozone generator

Ozone generator is a device that generates ozone (O3) by physical or chemical reactions such as corona discharge. Its basic principle is to stimulate oxygen molecules (O2) to ionize through electrical energy to produce free oxygen atoms (O), and then the free oxygen atoms and oxygen molecules combine to generate ozone. Specifically, the ozone generator uses the action of high-voltage electric field to decompose oxygen molecules into free oxygen atoms through an ionizer. Under the action of a strong electric field, the oxygen molecules are hit by electrons and break to form two oxygen atoms. These free oxygen atoms have unpaired electrons, so they have high reactivity and quickly combine with surrounding oxygen molecules to form ozone molecules.

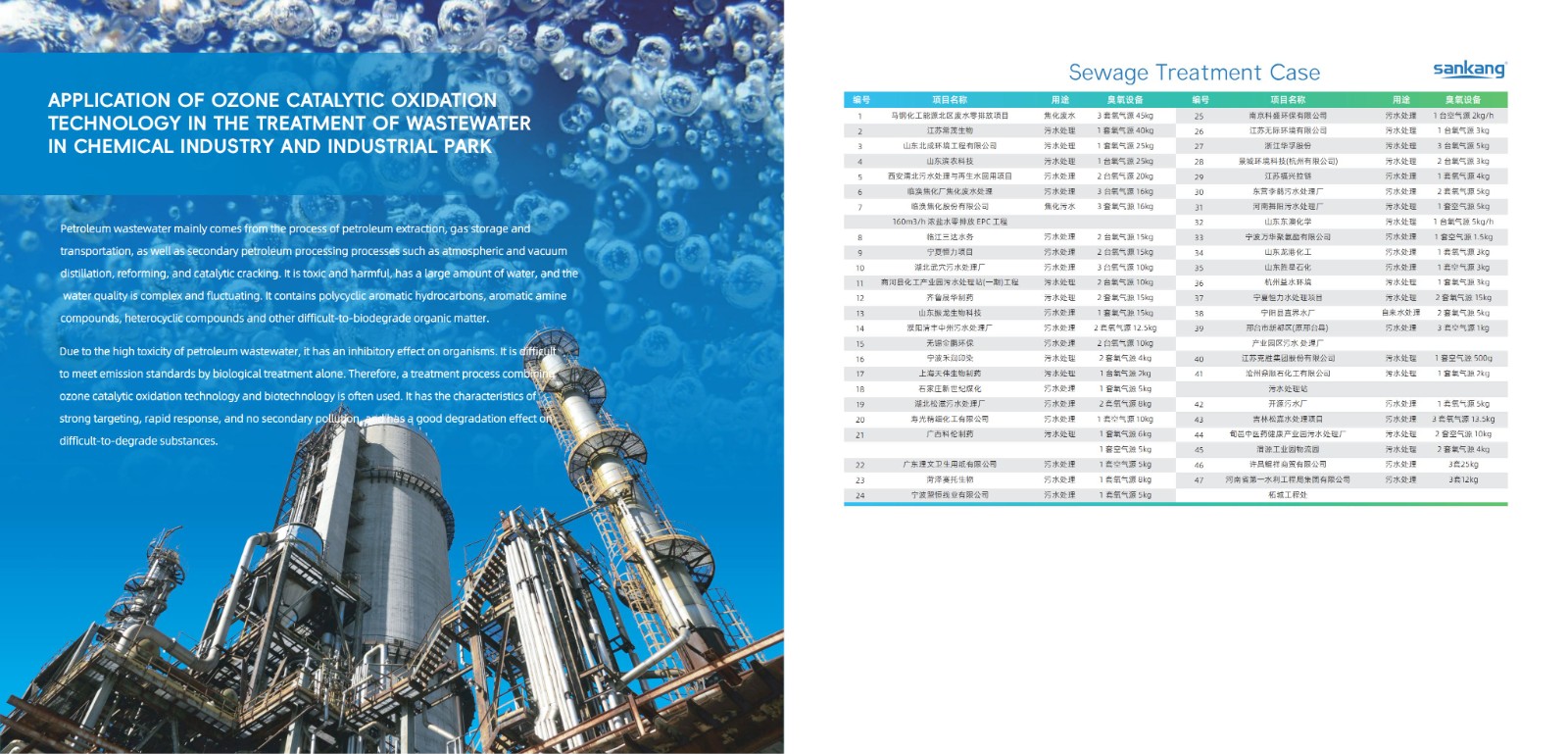

2. Application fields of ozone generators

Due to its strong oxidation ability, ozone generators have been widely used in many fields. At present, ozone has been widely used in many fields such as drinking water treatment, sewage treatment, air purification, chemical oxidation, pulp bleaching, food processing, medical and family, and its application scale, application depth and product specifications have reached unprecedented levels. Especially in water plants, pharmaceutical industry and food processing industry, ozone is widely used. In addition, ozone generators are also suitable for hotels, clothing factories, building material stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, advertising companies, energy and mining, construction projects, printing shops, retail stores, homes, restaurants and other places.

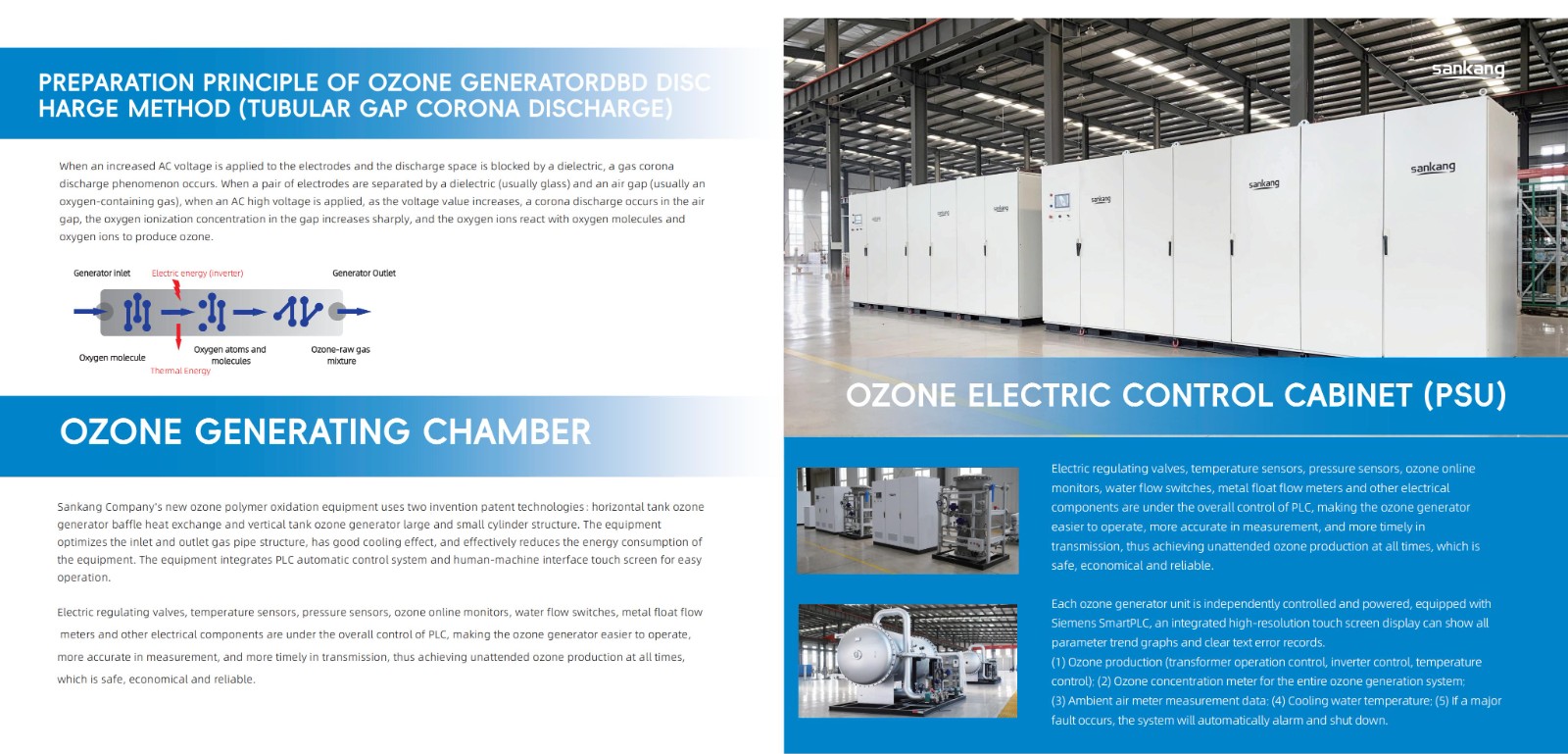

3. Technical specifications of 150KG ozone generator

Take a 150KG ozone generator as an example, its technical specifications are as follows:

1. **Production capacity**: This ozone generator can produce 750 liters of ozone per hour, which is suitable for large places or industrial applications that require a large amount of ozone.

2. **Power supply**: Usually 380V/3ph/50Hz power supply is used, and the allowable voltage fluctuation range is ±5%.

3. **Ozone concentration**: Depending on the gas source, the ozone concentration also varies. The ozone concentration of the oxygen source is usually between 120mg/L and 150mg/L, while the ozone concentration of the air source is between 20mg/L and 30mg/L.

4. **Working voltage and working frequency**: The working voltage is generally around 4.5kV, and the working frequency is between 800Hz and 1500Hz.

5. **Intake flow**: The intake flow of the oxygen source is between 6.7Nm3/h•kgO3 and 8.3Nm3/h•kgO3, while the intake flow of the air source is between 35Nm3/h•kgO3 and 50Nm3/h•kgO3.

6. **Cooling system**: The ozone generator uses a water cooling system. The cooling water temperature should be kept below 28℃, and the cooling water flow rate depends on the ozone output.

7. **Material and size**: The shell of the ozone generator is usually made of corrosion-resistant materials such as stainless steel or aluminum alloy. The size depends on the specific model, but it is generally larger to meet the needs of its high production capacity.