15Kg Ozone Generator

Ozonated polymer oxidation is a low-temperature oxidation technology in which an oxygen/ozone mixture is injected into the regenerator flue to oxidize NOX to the highly valent and water-soluble NO2 and N2O5, which are then scrubbed through the desulfurization tower and reacted with a base solution to form nitrate, or reacted with water to reduce nitrogen gas. Ozone low-temperature denitrification is a fast and highly automated denitrification process. Currently it is widely used in non-ferrous metals, heat, steel, industrial kilns and other air pollution control fields.

Product description:

Sankang's ozone polymer oxidation equipment provides a stable solution for addressing the issue of low-temperature flue gas (40-180℃) nitric oxide emissions in industries like industrial silicon and non-ferrous metal smelting. This is made possible through the patented technology of horizontal and vertical ozone generating chambers, combined with the application of an intelligent electrode-specific ozone generating unit and a water-cooled ozone generator. The system also includes a high-pressure connection device and features the proprietary ozone conversion control application system V1.0, a fault self-checking and reporting system V1.0, and intelligent frequency control software for the ozone generator. These patented technologies ensure 24-hour, full-load, trouble-free operation of the equipment.

Ozone Generator Preparation Principle:

The DBD (Dielectric Barrier Discharge) method, also known as Tubular Gap Corona Discharge, involves generating a gas corona discharge by applying a high AC voltage to electrodes separated by a dielectric barrier. Typically, the dielectric material is glass, and the air gap between the electrodes contains oxygen gas. As the AC voltage increases, a corona discharge occurs in the air gap, leading to a significant increase in ionization of the oxygen within the gap. The ionized oxygen molecules and ions interact, producing ozone as a result of these reactions. This method is widely used for efficient ozone generation in various applications.

Application:

Industrial ozone generators are primarily utilized in industries and fields that demand large-scale disinfection, oxidation processes, and odor control. Due to ozone's strong oxidizing properties, these generators are commonly applied in the following industrial scenarios:

Wastewater Treatment: Industrial wastewater often contains organic compounds, heavy metals, and hard-to-degrade harmful chemicals. Ozone is used to oxidize these organic pollutants, remove coloration, lower the Chemical Oxygen Demand (COD) of the water, and enhance the overall effectiveness of wastewater treatment.

Drinking Water Purification: In water treatment facilities, industrial ozone generators serve as a replacement for chlorine in disinfection processes. Ozone not only effectively eliminates bacteria and viruses but also removes organic contaminants, reducing both odor and harmful by-products in the water.

Cooling Water Circulation Treatment: In industrial cooling systems, water is prone to microorganism growth and scale formation. Ozone helps control these issues, extending the equipment's operational lifespan and maintaining system efficiency.

R&D Team:

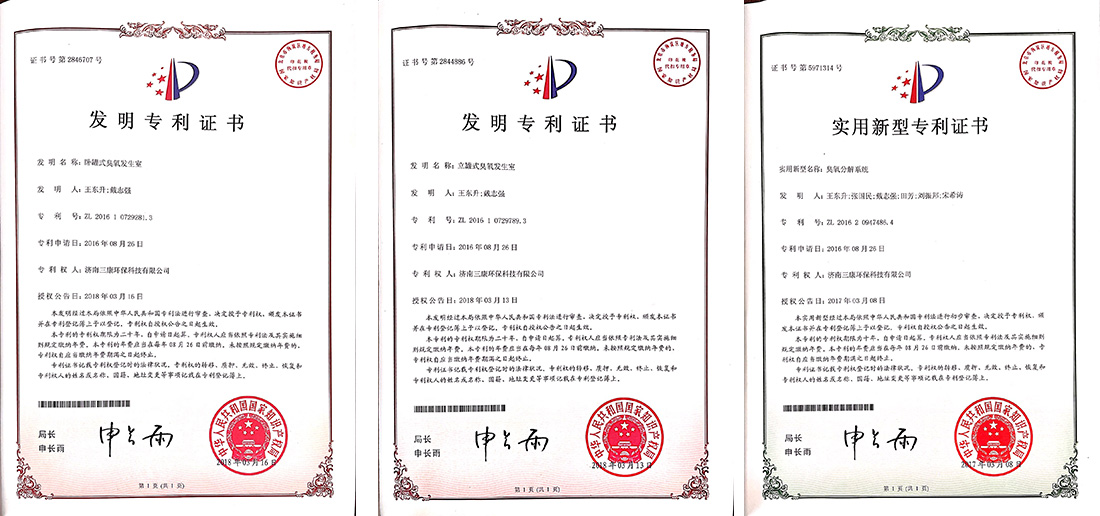

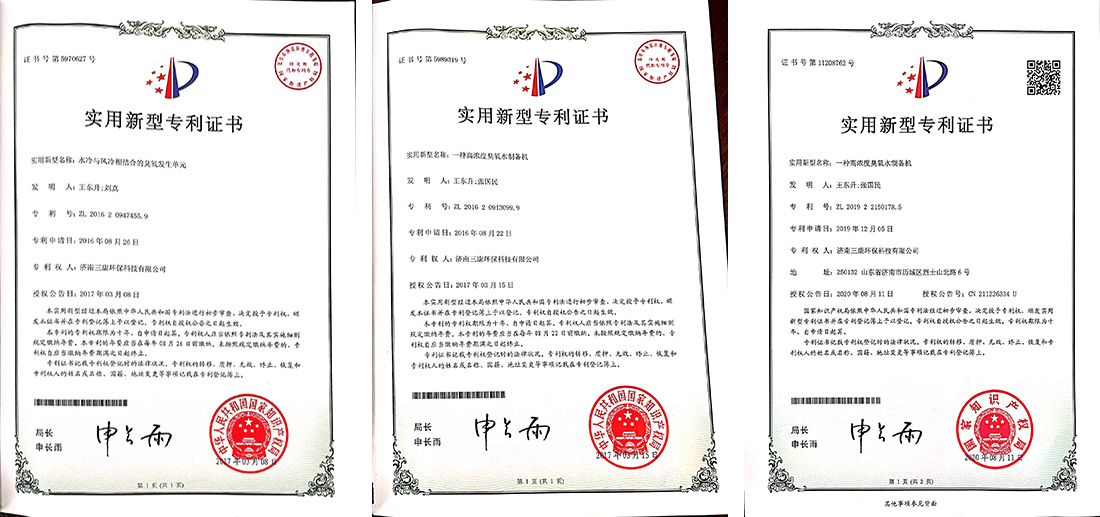

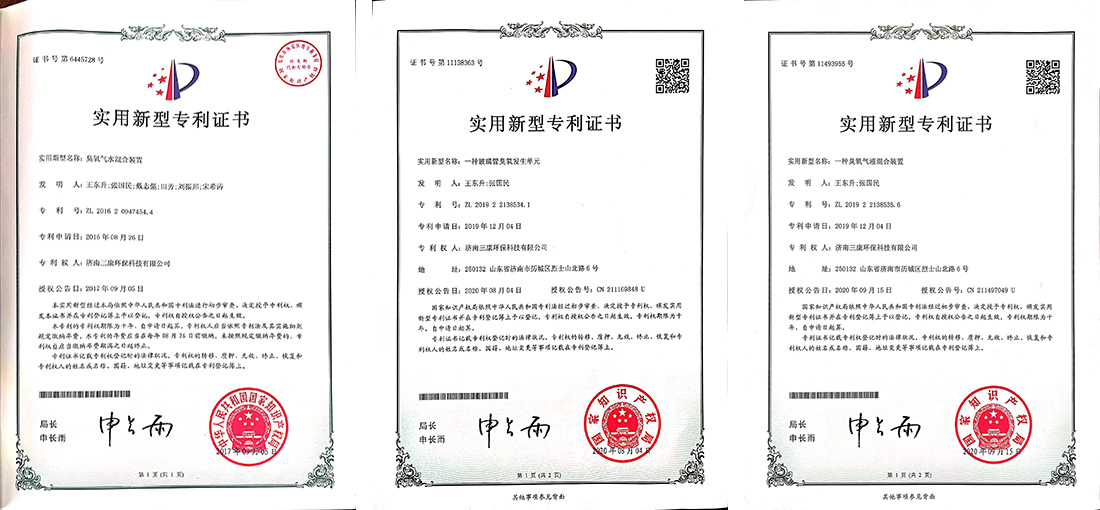

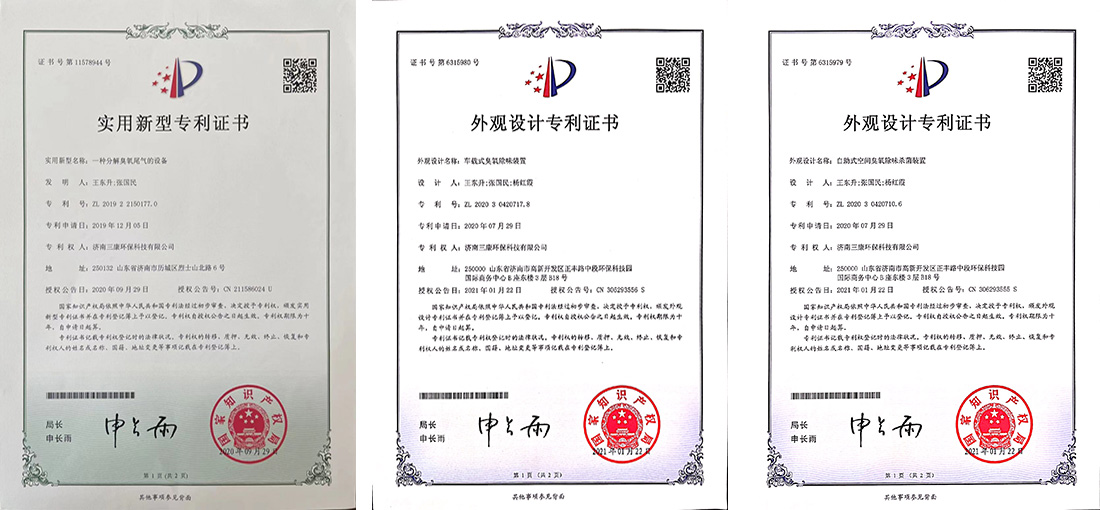

Wang Dongsheng, founder of Sankang Ozone, is a senior engineer and serves as the director of the China Environmental Protection Machinery Industry Association and the deputy director of the China Ozone Specialized Committee. He has led his company's team in over 50 internal product and technology R&D projects, resulting in 37 patented technologies, including 3 invention patents.

Wang Dongsheng's team successfully developed key technologies such as high borosilicate glass tube double air gap discharge and new ozone polymer oxidation equipment for the treatment of nitrogen oxide exhaust gases in non-ferrous metal smelting. They also became the first to master the full IGBT-controlled rectification primary resonance high-power 2WM power supply technology. Their ozone polymer oxidation equipment for treating nitrogen oxide exhaust gases in non-ferrous metal smelting passed the Science and Technology Achievement appraisal by the Chemical Association. The main technology of the product has reached a leading level domestically, with several patented innovations breaking international monopolies.This project Wang Dongsheng team average age of more than 6 years, all for undergraduate education and above, the team has obtained a total of 12 patents including invention and utility model patents, 2021, the team led the enterprise to obtain the Ministry of Industry, air pollution control standard conditions of the enterprise, 2023, Shandong Province, “specializing in fine, special and new” enterprises, 2023. Its products are selected as the first set of equipment in Shandong Province.

Honor Certificate: