16.5kg/h Ozone Generator

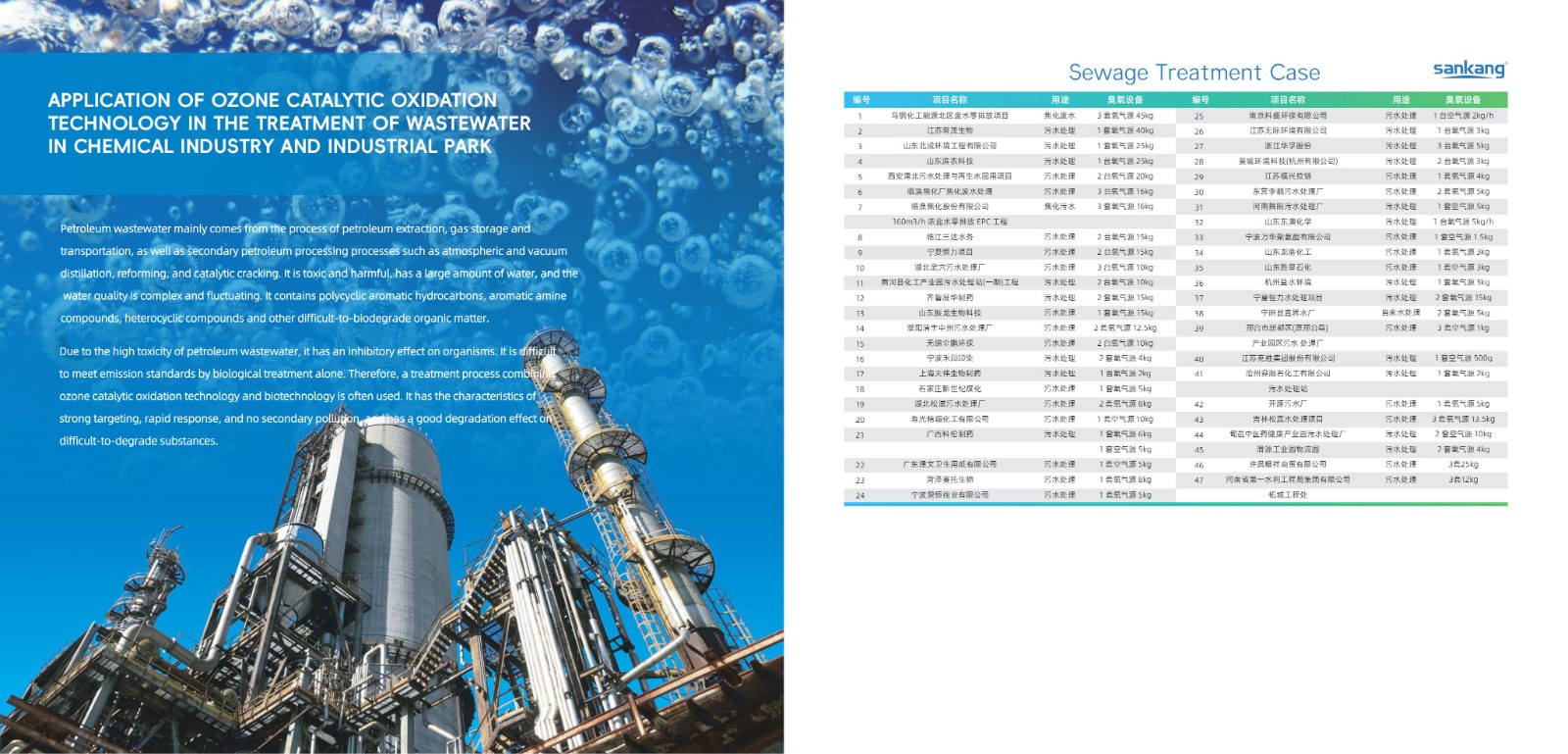

- **Water Treatment**: It is used for disinfection and sterilization of tap water, swimming pools, sewage treatment plants, etc., to improve water quality.

- **Air purification**: In hospitals, food processing plants, farms and other places, effectively remove bacteria, viruses, odors, etc. in the air.

- **Agricultural preservation**: ozone fumigation of fruits, vegetables, grains, etc., to extend the shelf life and reduce pesticide residues.

- **Industrial Manufacturing**: In semiconductor, optoelectronics, medicine and other industries, it is used for material surface cleaning, oxide layer removal, etc.

In modern industry and life, air quality has increasingly become the focus of people's attention. With the advancement of science and technology, various air purification technologies have emerged, among which ozone generators have become the preferred equipment in many occasions due to their efficient oxidation capacity and wide range of applications. This article will introduce a 16.5KG ozone generator in detail, and conduct a comprehensive analysis from its basic principle, working characteristics, application fields and maintenance.

#### First, the basic principle of ozone generator

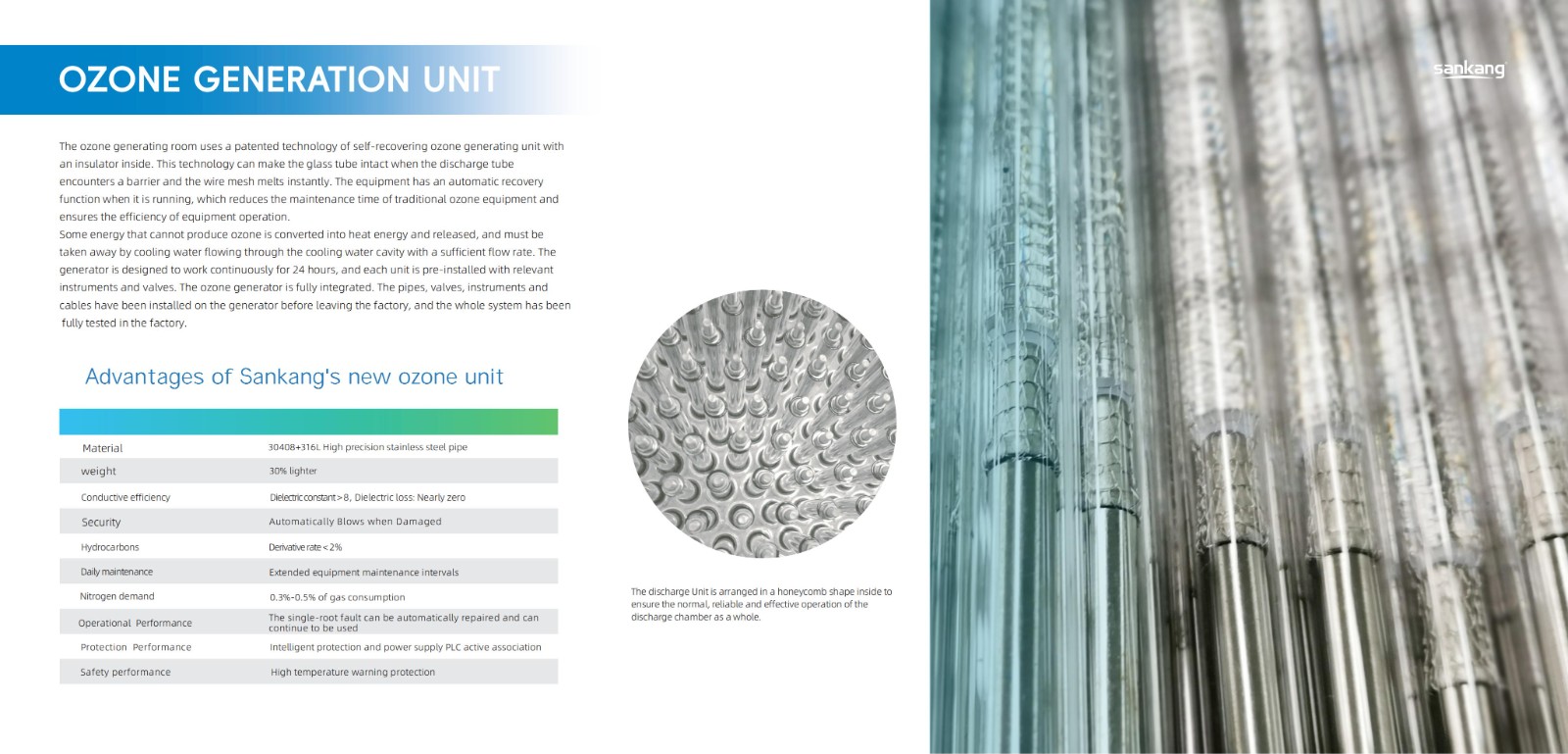

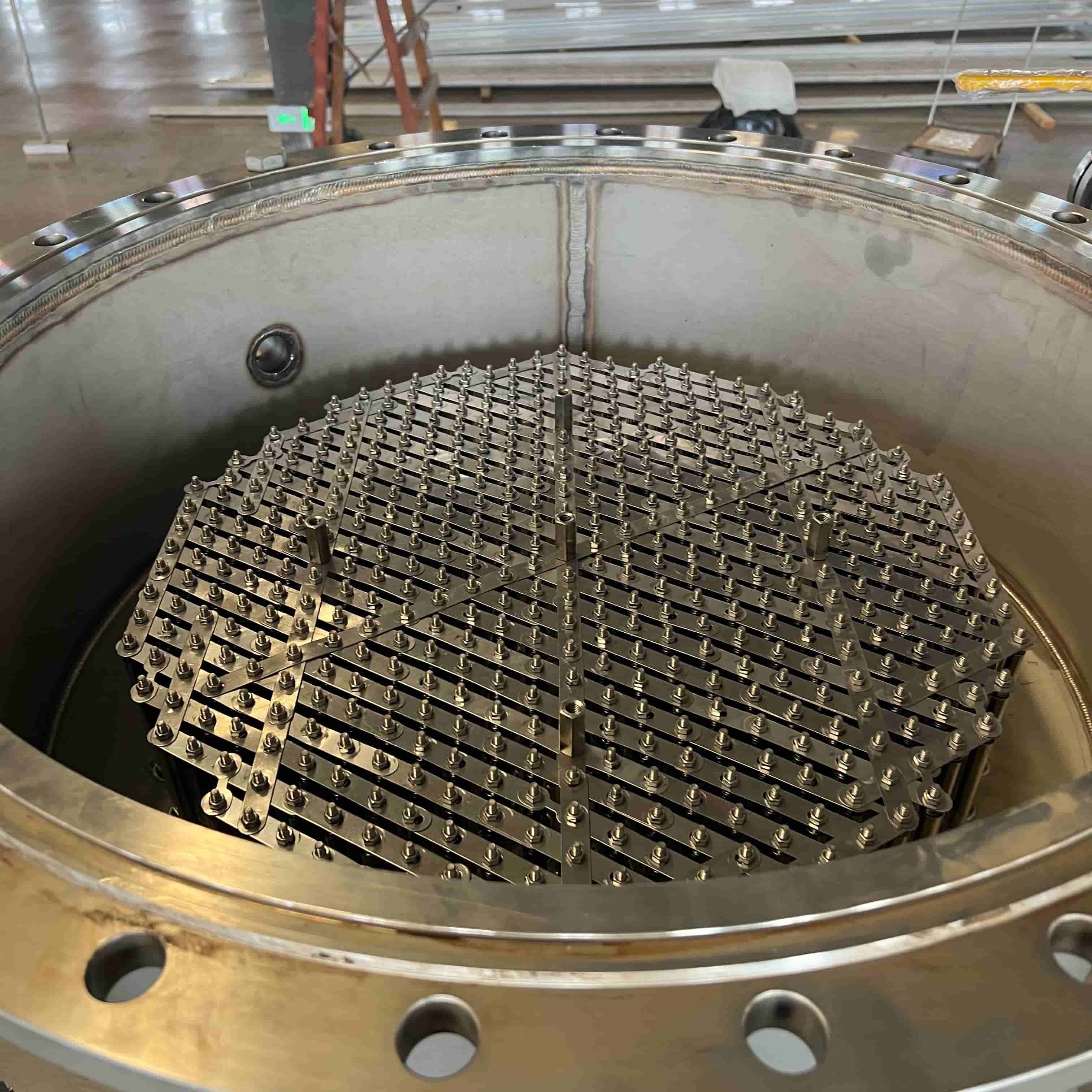

Ozone (O₃) is an allotrope of oxygen that is made up of three oxygen atoms and is extremely oxidizing. Ozone generators take advantage of this property to excite and decompose oxygen molecules (O₂) in the air into individual oxygen atoms (O) through high-voltage electric fields or ultraviolet light, which then combine with undecomposed oxygen molecules to form ozone (O₃). The 16.5KG ozone generator, as the name suggests, means that it is equipped with about 16.5kg of ozone generation medium or related components, which can continuously and stably produce a certain amount of ozone gas.

#### Second, working characteristics and performance parameters

The 16.5KG ozone generator is designed with high efficiency and durability in mind. Key features include:

- **High Yield**: Depending on the model, the unit can produce hundreds to thousands of grams of ozone per hour, making it suitable for large-scale air purification needs.

- **Intelligent Control**: Equipped with an advanced control system, the ozone output can be adjusted according to the actual demand, to achieve precise control, and at the same time, it is equipped with safety measures such as overload protection and short circuit protection.

- **Energy saving and environmental protection**: The use of high-efficiency power supply and cooling system to reduce energy consumption and ensure the long-term stable operation of the equipment.

- **Solid material**: The shell and internal components are made of corrosion-resistant and high-temperature resistant materials to adapt to various harsh environments.

In addition, performance parameters such as ozone concentration, input voltage, operating frequency, noise level, etc., are also important factors to consider when selecting and using such equipment.