180KG/h Ozone Generator

Highly efficient and energy-saving, ozone utilization rate is as high as 95%

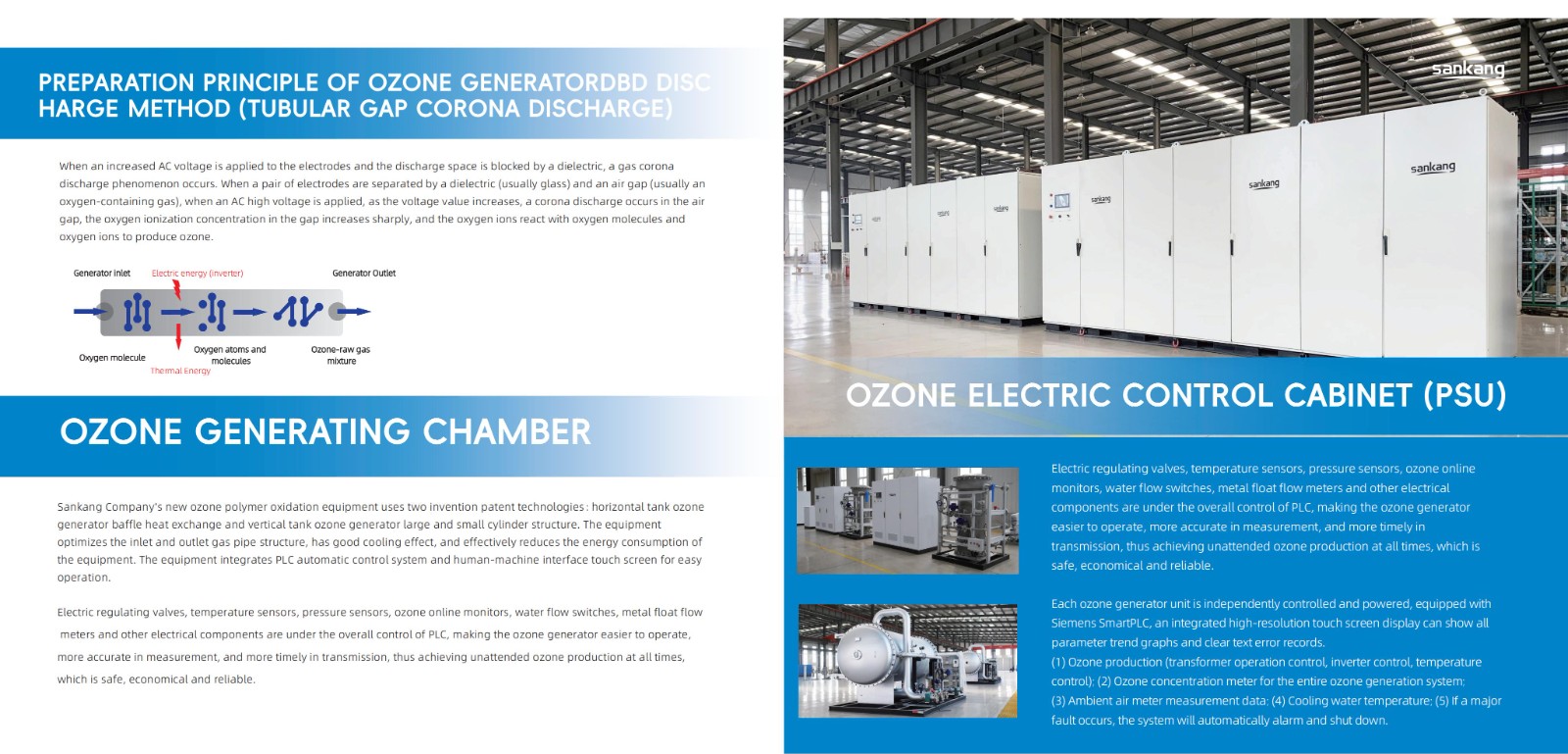

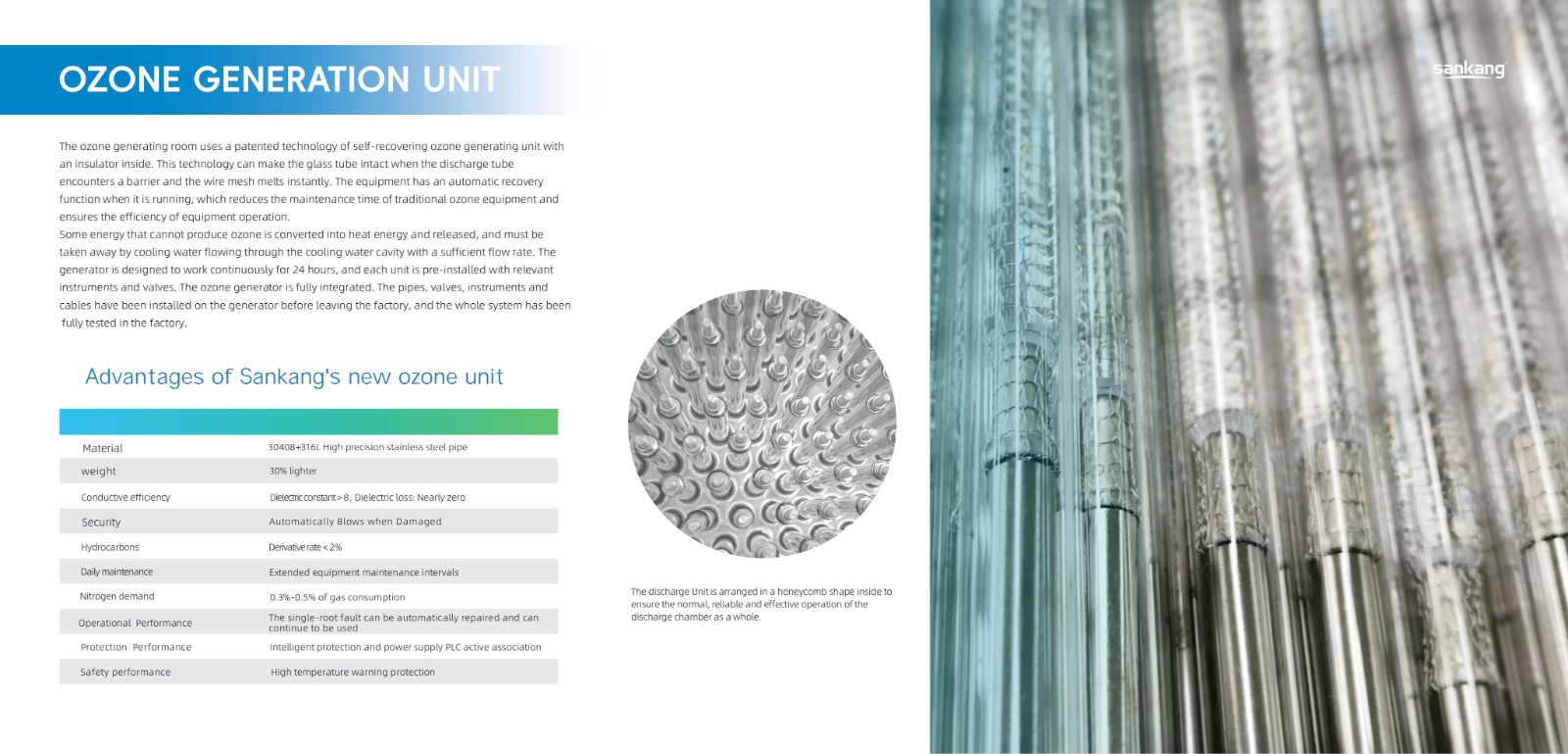

The application of IGBT inverter medium-frequency high-voltage power supply can effectively improve ozone generation efficiency, achieve high efficiency and energy saving, and ensure continuous and stable operation.

The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.

The ozone system uses water cooling technology to maintain efficient and stable ozone production.

The discharge tube adopts advanced high borosilicate tube discharge technology.

The vacuum thermal regeneration system provides high-quality air to the generating unit and increases the ozone concentration.

The equipment works in negative pressure mode, which effectively avoids ozone leakage and is safe and reliable.

The equipment carries out advanced PLC automatic control and realizes the integration of ozone generation system, air source system, cooling system and control system.

Optimized mechanical design, compact structure, low maintenance workload.

Low harmonic pollution, low power consumption, silent design.

Effective balancing of ejector suction obstruction.

In the field of modern environmental protection and water treatment, ozone generators, as an efficient oxidation disinfection equipment, are playing an increasingly important role. This article will introduce a 180kg/h ozone generator in detail, and explore its working principle, application field, technical characteristics and market value.

1. Working principle

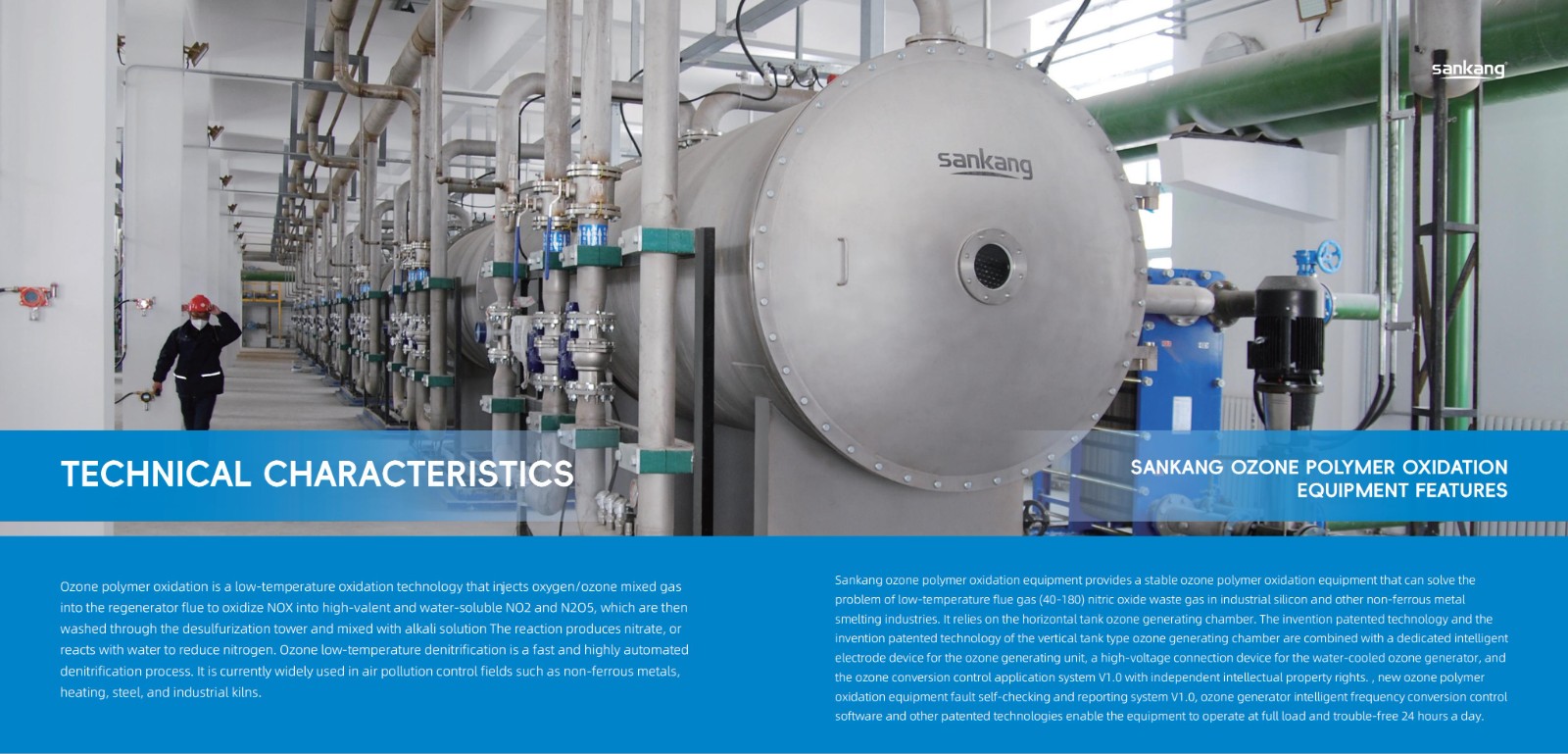

Ozone generator is a device that generates ozone (O3) by physical or chemical reactions such as corona discharge. Its core principle is to stimulate oxygen molecules (O2) to ionize through electrical energy to produce free oxygen atoms (O), and then the free oxygen atoms and oxygen molecules combine to generate ozone. Specifically, the ozone generator uses the action of a high-voltage electric field to decompose oxygen molecules into free oxygen atoms through an ionizer. Under the action of a strong electric field, the oxygen molecules are hit by electrons and break to form two oxygen atoms. These free oxygen atoms have unpaired electrons and therefore have high reactivity. They quickly combine with surrounding oxygen molecules to form ozone molecules. Ozone generators usually use condensation or electrospinning membrane methods to achieve ozone generation and collection. In the condensation method, ozone is adsorbed by contact with the condensing agent to form liquid ozone; while the electrospinning membrane method uses special textile materials to separate oxygen molecules and ozone molecules under the action of the electric field, so that ozone is concentrated separately.

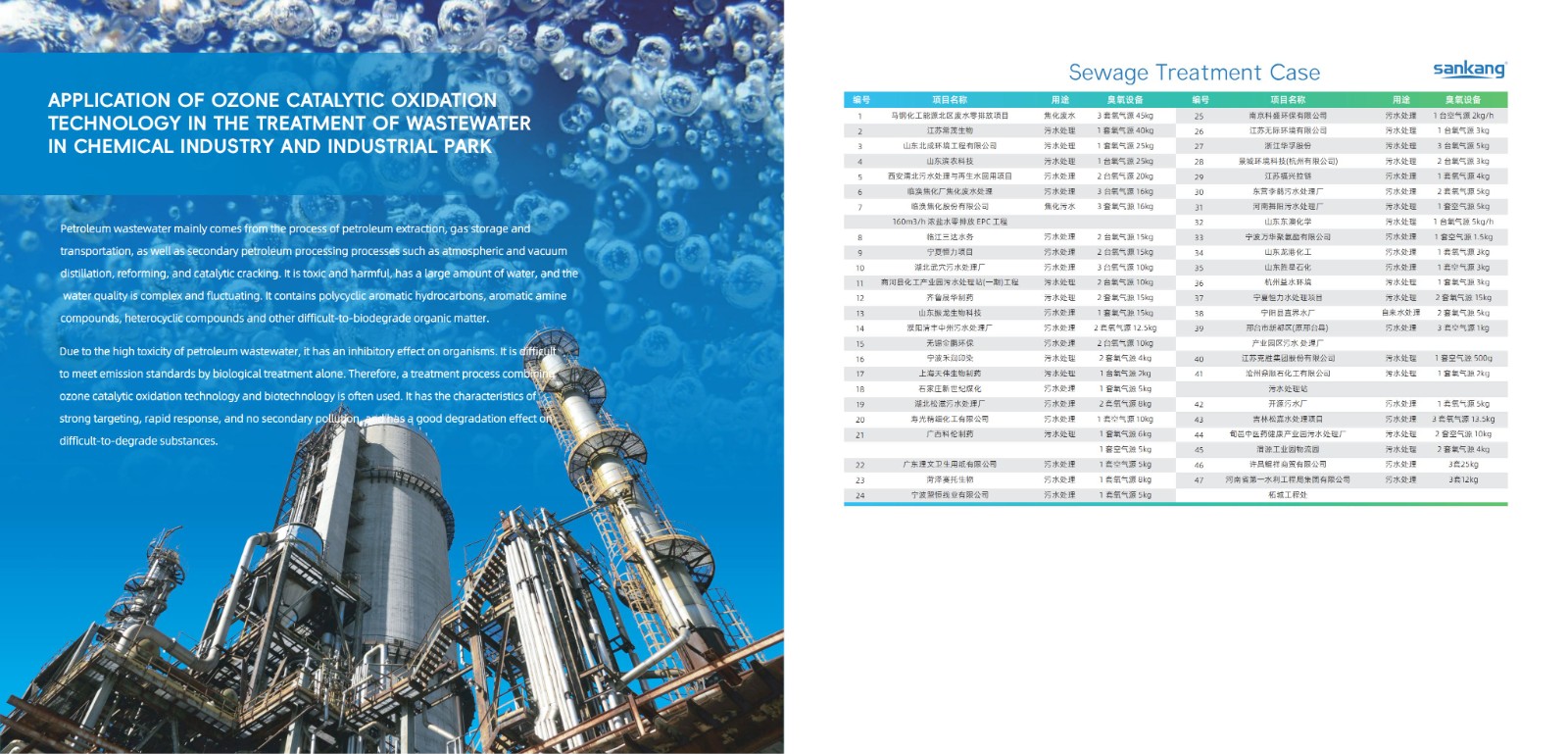

2. Application fields

The 180kg/h ozone generator has become the preferred equipment for many industries due to its efficient ozone generation capacity and wide application fields. It is suitable for the treatment of industrial and domestic wastewater, and can quickly oxidize and decompose organic matter, inorganic matter and harmful substances in water to improve water quality. In addition, the equipment is also widely used in hotels, garment factories, building materials stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, advertising companies, energy and mining, construction sites, printing shops, restaurants and other fields. In the food and beverage industry, ozone generators can be used for immersion sterilization of raw material surfaces to form sterile raw material surfaces; in the processing of aquatic products, the use of high-concentration ozone water for spray sterilization or immersion sterilization can control the sanitary indicators of aquatic products and avoid the problem of excessive chlorine residue caused by the use of chlorides. In the production process of liquid food processing (such as beverages, juices, etc.) and pharmaceutical factories, high-concentration ozone water can be used to soak and flush pipes, production equipment and containers to achieve efficient sterilization.