30KG/h Ozone Generator

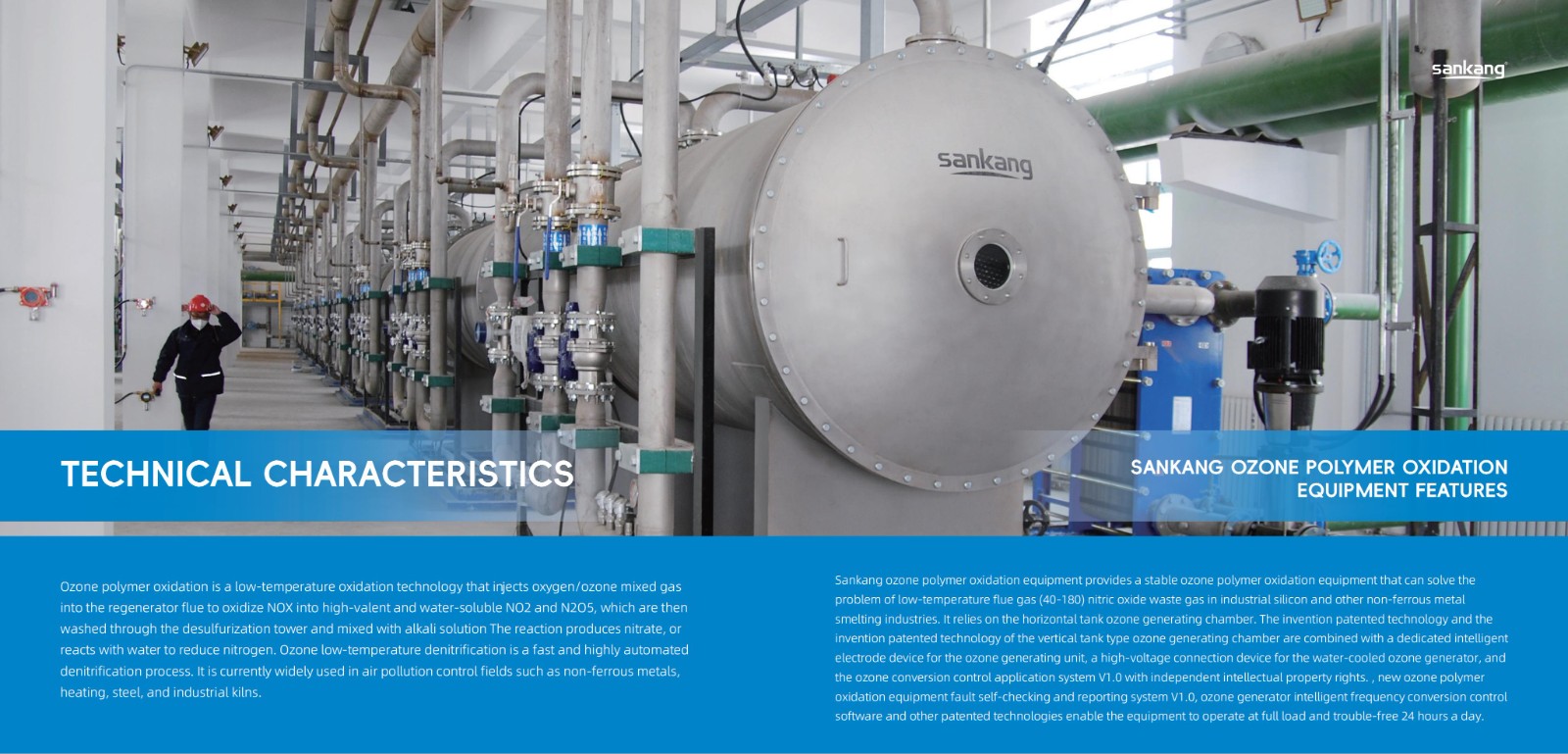

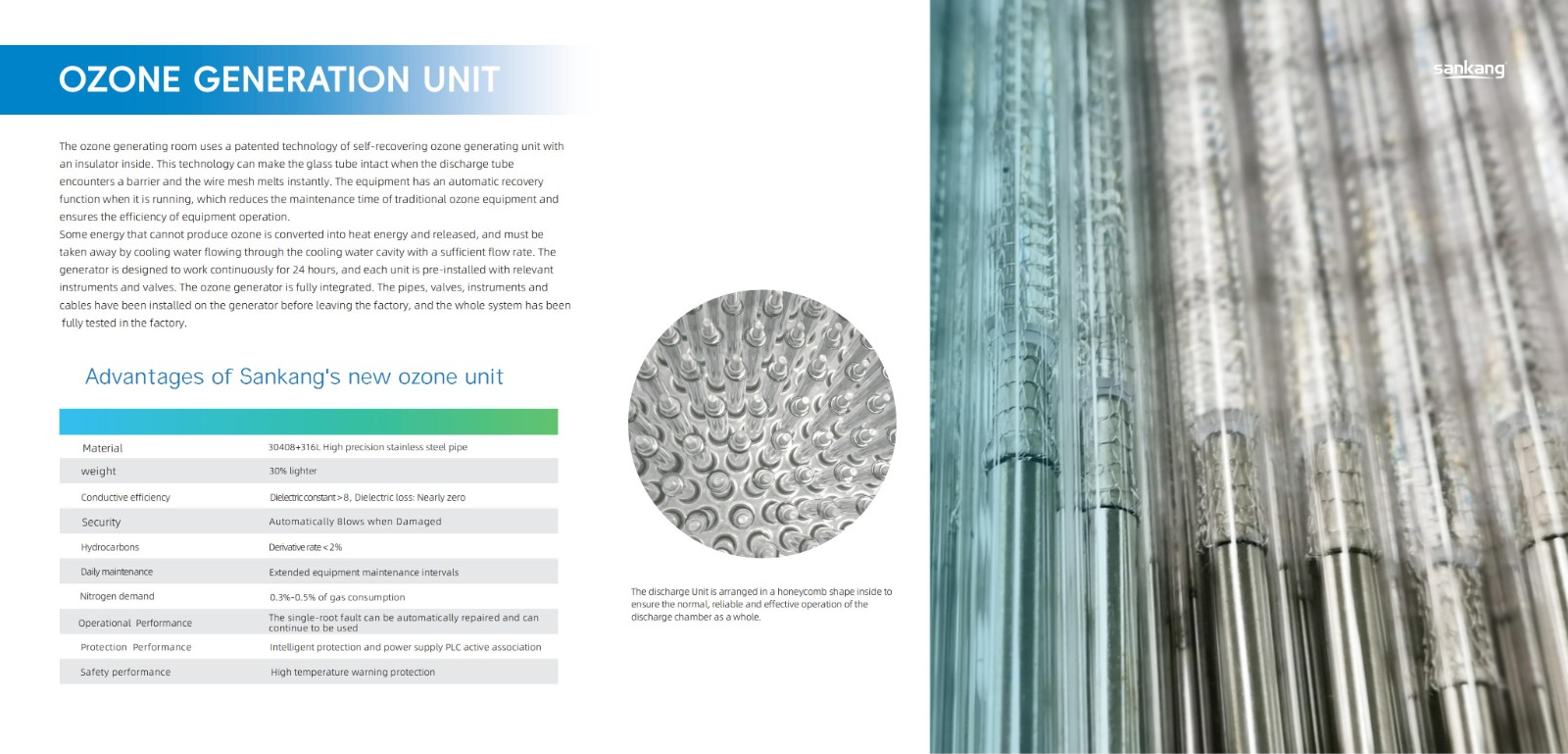

Sankang ozone polymer oxidation equipment provides a stable ozone polymer oxidation equipment that can solve the problem of low-temperature flue gas (40-180℃) nitric oxide waste gas in industrial silicon and other non-ferrous metal smelting industries. It relies on the horizontal tank ozone generating chamber. The invention patented technology and the invention patented technology of the vertical tank type ozone generating chamber are combined with a dedicated intelligent electrode device for the ozone generating unit, a high-voltage connection device for the water-cooled ozone generator, and the ozone conversion control application system V1.0 with independent intellectual property rights. , new ozone polymer oxidation equipment fault self-checking and reporting system V1.0, ozone generator intelligent frequency conversion control software and other patented technologies enable the equipment to operate at full load and trouble-free 24 hours a day.

Ozone generator for large wastewater treatment system: maximum ozone machine 80kg, 100kg, 120kg, 150kg

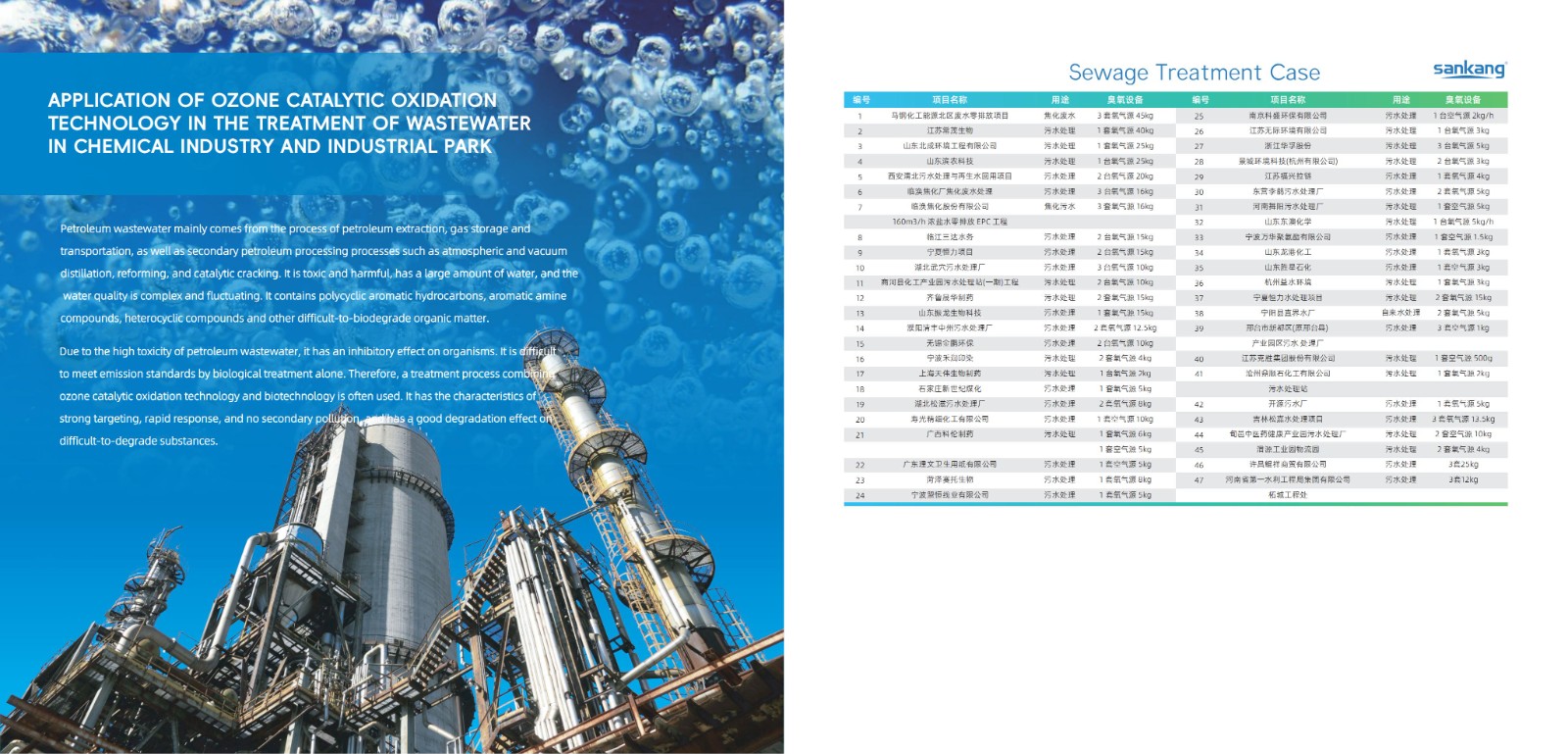

Today, with environmental protection and water resources becoming increasingly tense, wastewater treatment has become an indispensable part of industrial production. As an important equipment for treating a large amount of industrial wastewater, the performance and efficiency of large-scale wastewater treatment systems are directly related to the effect of water purification and environmental protection. In these systems, ozone generators, as key components, play a vital role. This article will introduce in detail the ozone generators used in large wastewater treatment systems, especially large ozone machines with maximum ozone production of 80kg, 100kg, 120kg and 150kg, and explore their working principles, application advantages, and selection and maintenance points.

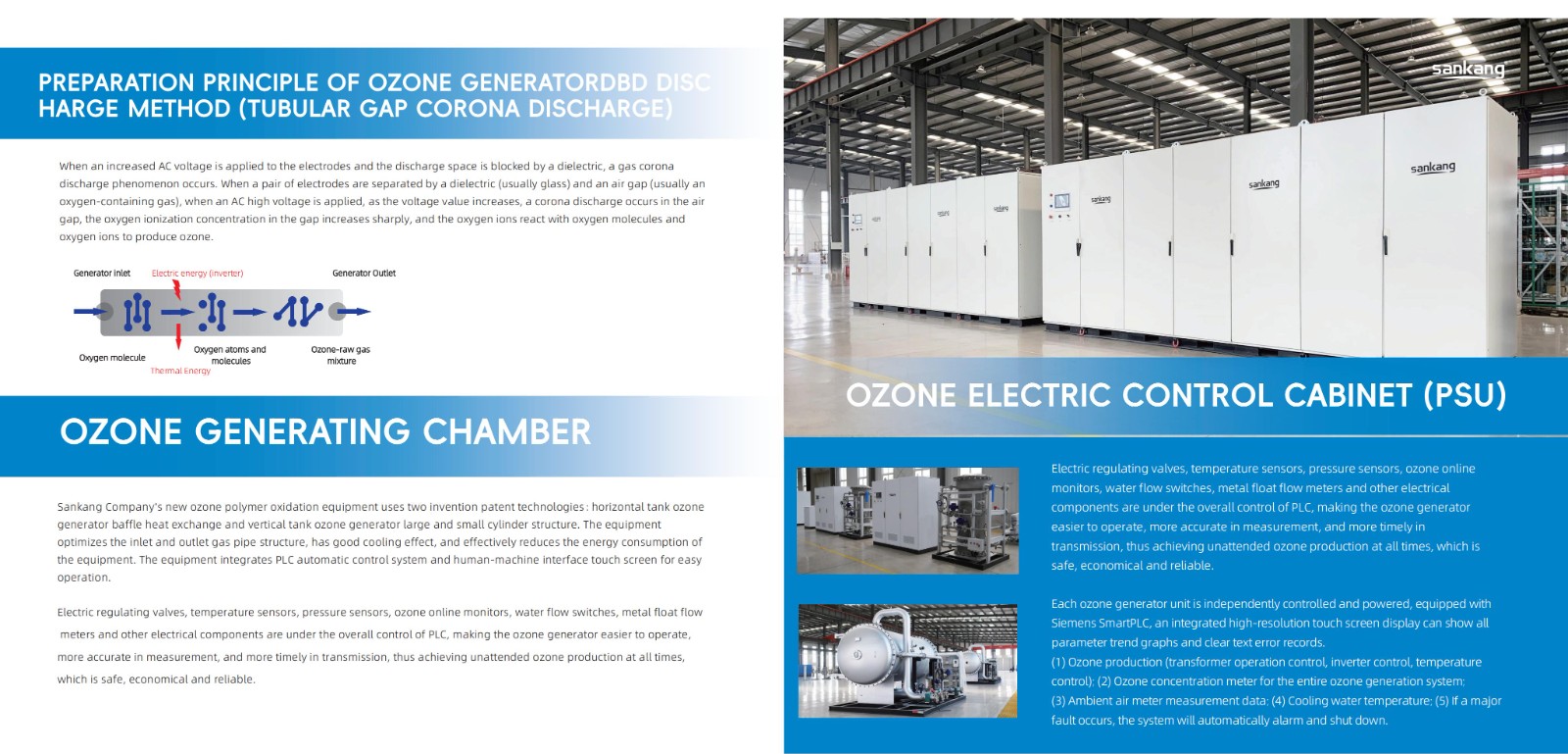

1. Working principle of ozone generator

Ozone generator is a device that converts oxygen (O2) in the air into ozone (O3) by electrolysis, ultraviolet light or high-voltage discharge. In the field of wastewater treatment, high-voltage discharge method is widely used because of its high efficiency and stability. This method uses high voltage to generate discharge in the air gap, so that oxygen molecules gain energy under the action of the electric field, and then split and recombine into ozone molecules. Ozone is a strong oxidant with extremely high reactivity. It can effectively decompose organic matter in wastewater, kill bacteria and viruses, remove odor and color, and is an important means to improve the effect of wastewater treatment.

2. Application advantages of large-scale ozone generators

1. Efficient treatment capacity: Large-scale ozone generators with a maximum ozone output of 80kg, 100kg, 120kg or even 150kg can meet the needs of large-scale wastewater treatment, quickly improve the oxidation capacity of wastewater, accelerate the decomposition process of pollutants, and shorten the treatment cycle.

2. Energy saving and environmental protection: The ozone generator does not produce secondary pollution during operation, and the ozone preparation efficiency is high, and the energy consumption is relatively low. At the same time, the natural decomposition product of ozone is oxygen, which will not cause additional burden on the environment, which is in line with the concept of green and sustainable development.

3. Strong adaptability: Large ozone generators can flexibly adjust the amount of ozone added according to the water quality characteristics and treatment requirements of different wastewaters to achieve precise control. They are suitable for wastewater treatment in various industries such as chemical, printing and dyeing, pharmaceutical, and papermaking.

4. Improve water quality standards: The strong oxidizing properties of ozone effectively remove difficult-to-degrade organic matter, heavy metal ions, and microorganisms in water, significantly improving the quality of effluent water to meet higher discharge standards or reuse requirements.