32kg Ozone Generator

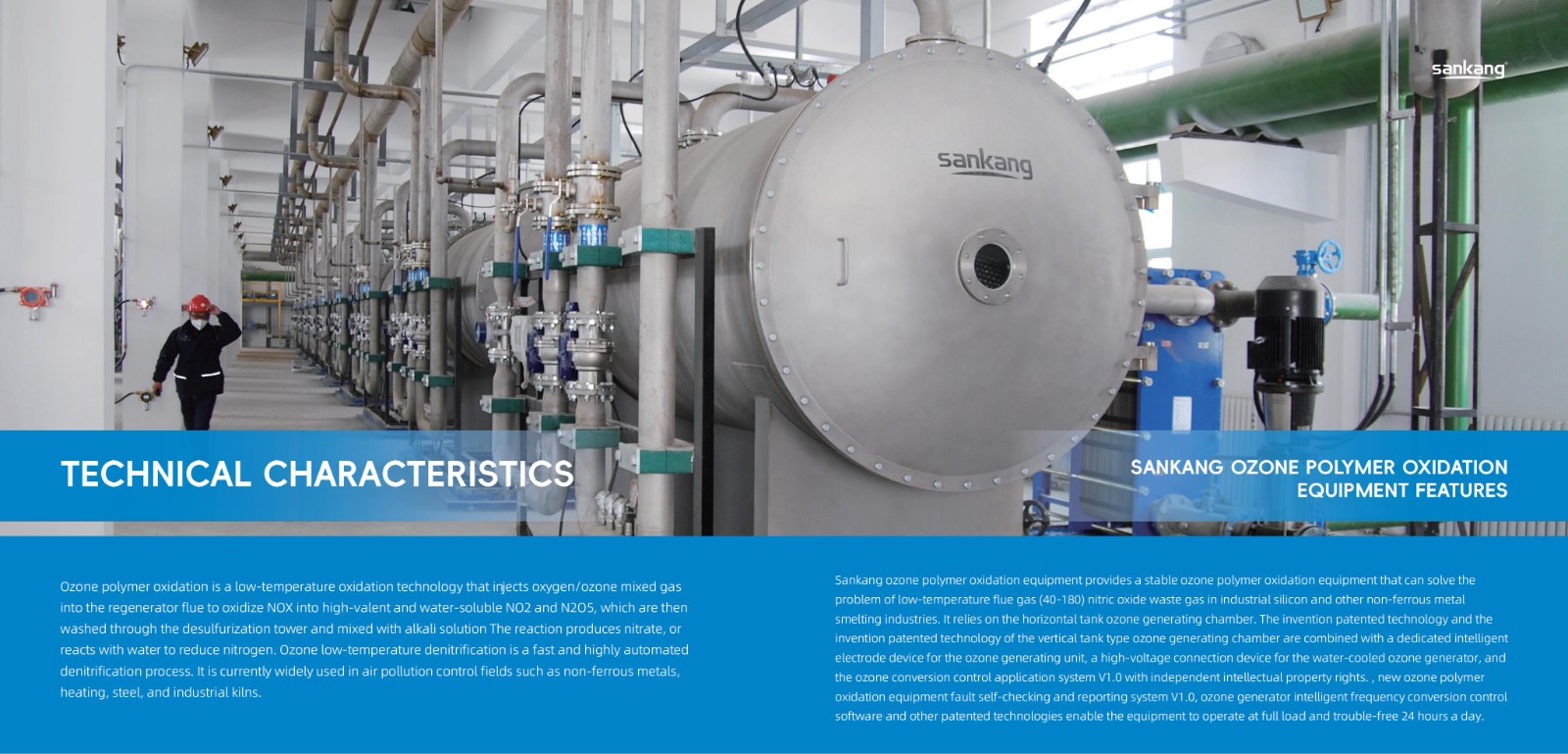

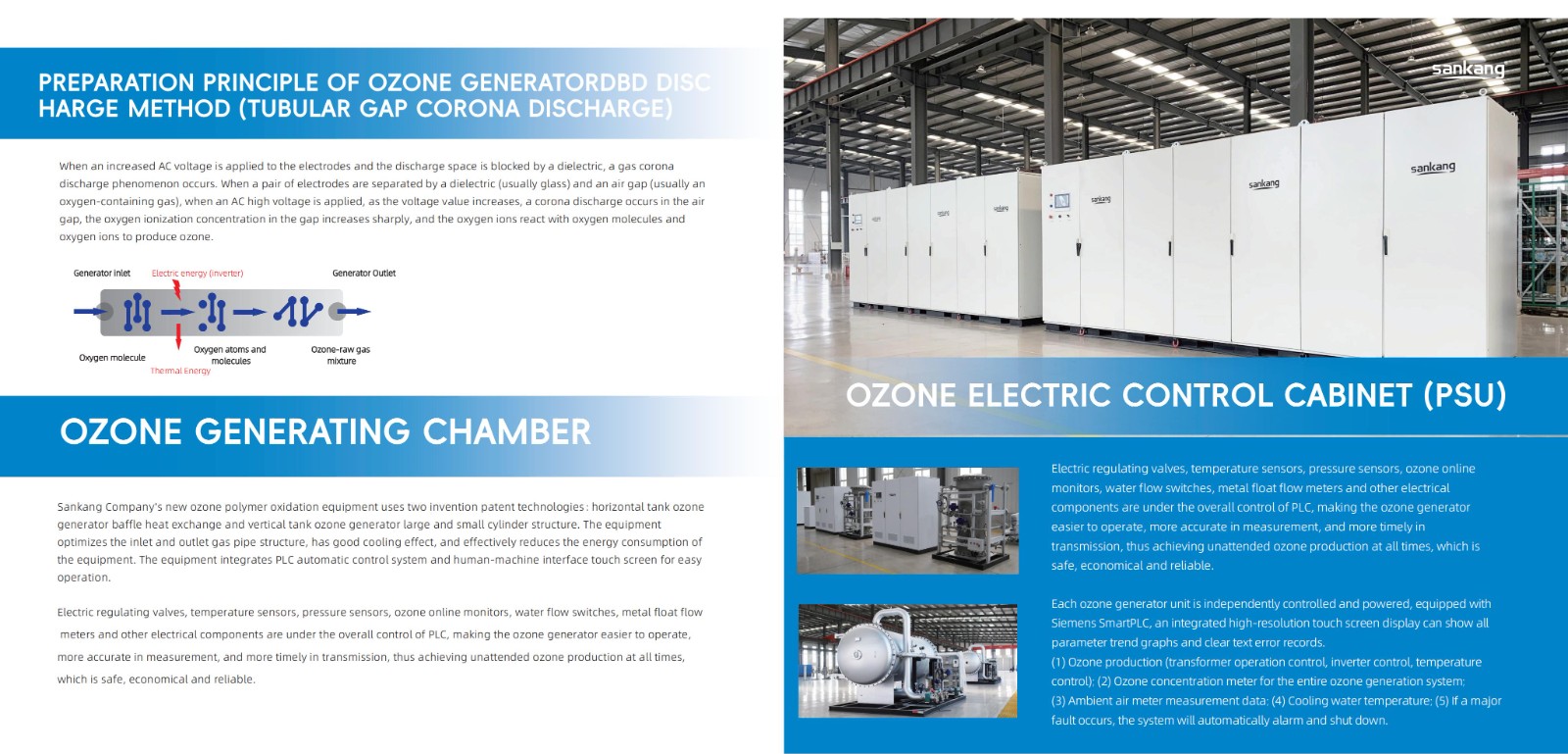

Sankang's new ozone polymer oxidation equipment applies two patented invention technologies: horizontal tank-type ozone generating chamber baffle plate heat exchange and vertical tank-type ozone generating chamber large and small cylinder structure. The equipment optimizes the structure of the air inlet and outlet ducts, has good cooling effect, and effectively reduces the energy consumption of the equipment. The equipment integrates a PLC automatic control system and a human-machine interface touch screen, making it easy to operate.

Electrical control valves, temperature sensors, pressure sensors, ozone online monitors, water flow switches, metal float flowmeters and other electrical components are under the overall control of PLC, making the ozone generator more convenient to operate, more accurate in measurement, and more timely in transmission, realizing ozone The whole production period is unattended, safe, economical and reliable.

Large ozone generator for chemical oxidation

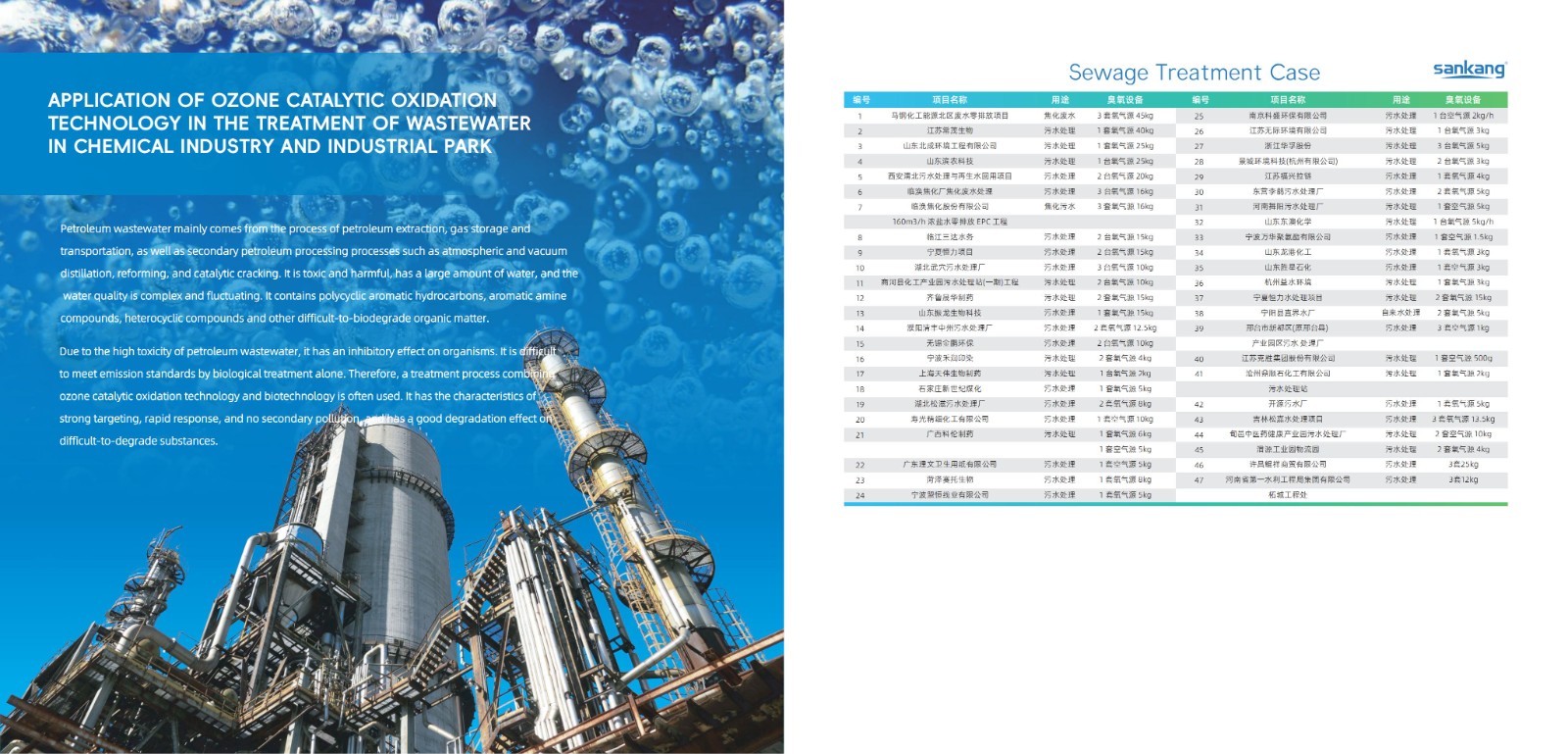

In the modern chemical industry, the oxidation process plays a vital role. It not only promotes the progress of chemical reactions, but also effectively removes pollutants in water and improves water quality. Among many oxidants, ozone stands out for its high efficiency and environmental protection, becoming the preferred choice in water treatment, air purification and chemical production. In order to meet the needs of large-scale oxidation treatment, large-scale ozone generators have emerged and become indispensable equipment in these fields. This article will deeply explore the working principle, structural characteristics, application fields and future development trends of large-scale ozone generators for chemical oxidation.

#### Working principle

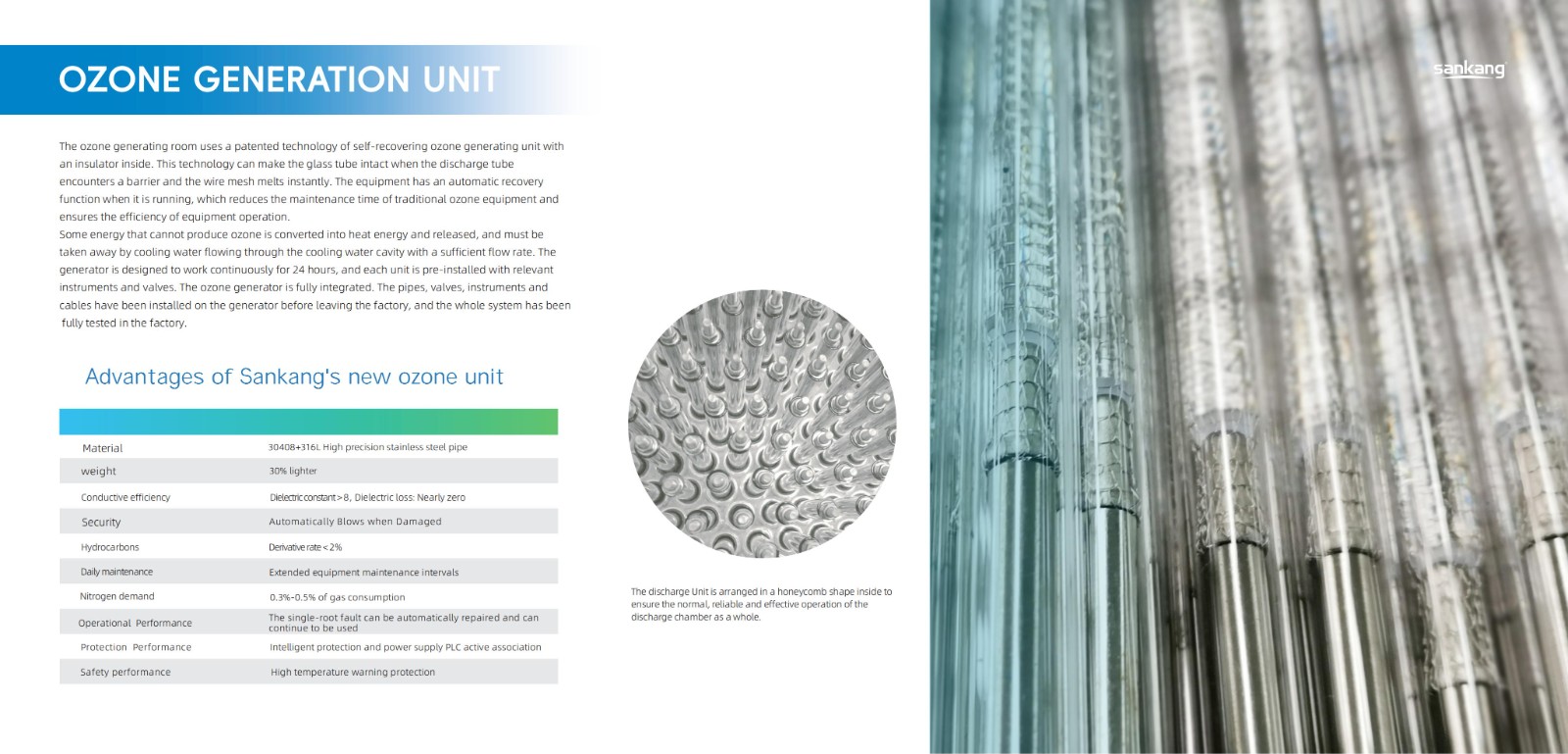

Large-scale ozone generators mainly use high-voltage electric field discharge technology to generate ozone. The basic principle is to pass dry, pure oxygen or air through a high-voltage electric field. When the electric field strength reaches a certain threshold, oxygen molecules (O2) are excited and decomposed into oxygen atoms (O) under the action of the electric field. These oxygen atoms then combine with undecomposed oxygen molecules to form ozone molecules (O3). This process is a typical corona discharge process, which requires precise control of parameters such as electric field strength, gas flow, temperature and humidity to ensure efficient generation of ozone.

#### Structural features

Large-scale ozone generators are usually composed of several parts: gas supply system, cooling system, high-voltage power supply, ozone generation chamber and control system.

- **Gas supply system**: Responsible for providing high-quality oxygen or air as raw materials to ensure the purity and efficiency of ozone generation.

- **Cooling system**: Since a large amount of heat is generated during the ozone generation process, an efficient cooling system is essential to maintain stable operation of the equipment.

- **High-voltage power supply**: Provides the necessary electrical energy to stimulate gas discharge, is the core component of ozone generation, and its stability and efficiency directly affect ozone production.

- **Ozone generation chamber**: It is the main place for ozone generation. Its design needs to optimize the electric field distribution, reduce energy loss, and increase ozone concentration.

- **Control system**: Integrated automatic control, monitoring and adjusting various parameters to ensure that the equipment operates in the best condition.

#### Application fields

Large-scale ozone generators have shown wide application value in many fields due to their powerful oxidation ability:

1. **Water treatment**: used for deep treatment of tap water, sewage and industrial wastewater, effectively removing organic matter, color, odor and killing microorganisms, and improving water quality standards.

2. **Air purification**: used for air disinfection in hospitals, food processing, pharmaceuticals and other industries to reduce the content of bacteria, viruses and harmful gases in the air.

3. **Chemical production**: used as an oxidant to participate in chemical reactions, such as synthesizing organic compounds, catalyst regeneration, etc., to improve production efficiency and product quality.

4. **Agriculture and food preservation**: used for preservation of agricultural products and food, extending storage period and reducing pesticide residues.

#### Future development trends

With the enhancement of environmental awareness and the continuous advancement of technology, large-scale ozone generators are developing in a more efficient, smarter and more environmentally friendly direction:

- **Technological innovation**: research and develop new discharge technologies and materials to improve ozone generation efficiency and reduce energy consumption.

- **Intelligent control**: Integrate advanced technologies such as the Internet of Things and big data to achieve remote monitoring and intelligent adjustment, and improve the level of operation management.

- **Modular design**: It is easy to flexibly configure according to actual needs to meet the application needs of different scales and scenarios.

- **Green energy saving**: Optimize the cooling system and energy recovery mechanism, reduce carbon emissions, and promote sustainable development.

In short, large-scale ozone generators used for chemical oxidation, with their unique advantages, play an important role in many fields such as environmental protection, industrial production and daily life. With the continuous advancement of technology and the in-depth expansion of applications, large-scale ozone generators will show a broader prospect in promoting green chemistry and promoting sustainable development.