35KG/h Ozone Generator

The ozone system uses water cooling technology to maintain efficient and stable ozone production.

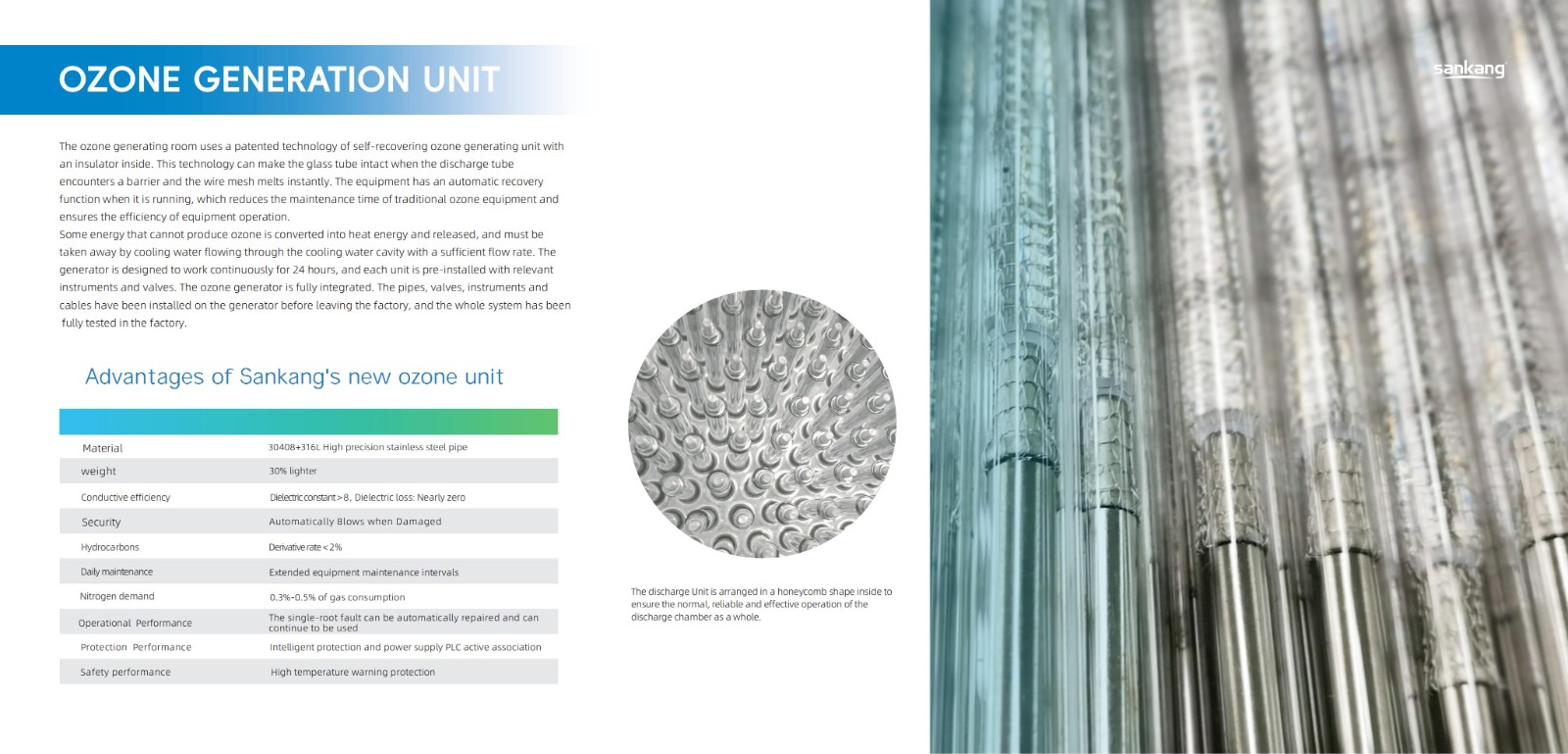

The discharge tube adopts advanced high borosilicate tube discharge technology.

The vacuum thermal regeneration system provides high-quality air to the generating unit and increases the ozone concentration.

The equipment works in negative pressure mode, which effectively avoids ozone leakage and is safe and reliable.

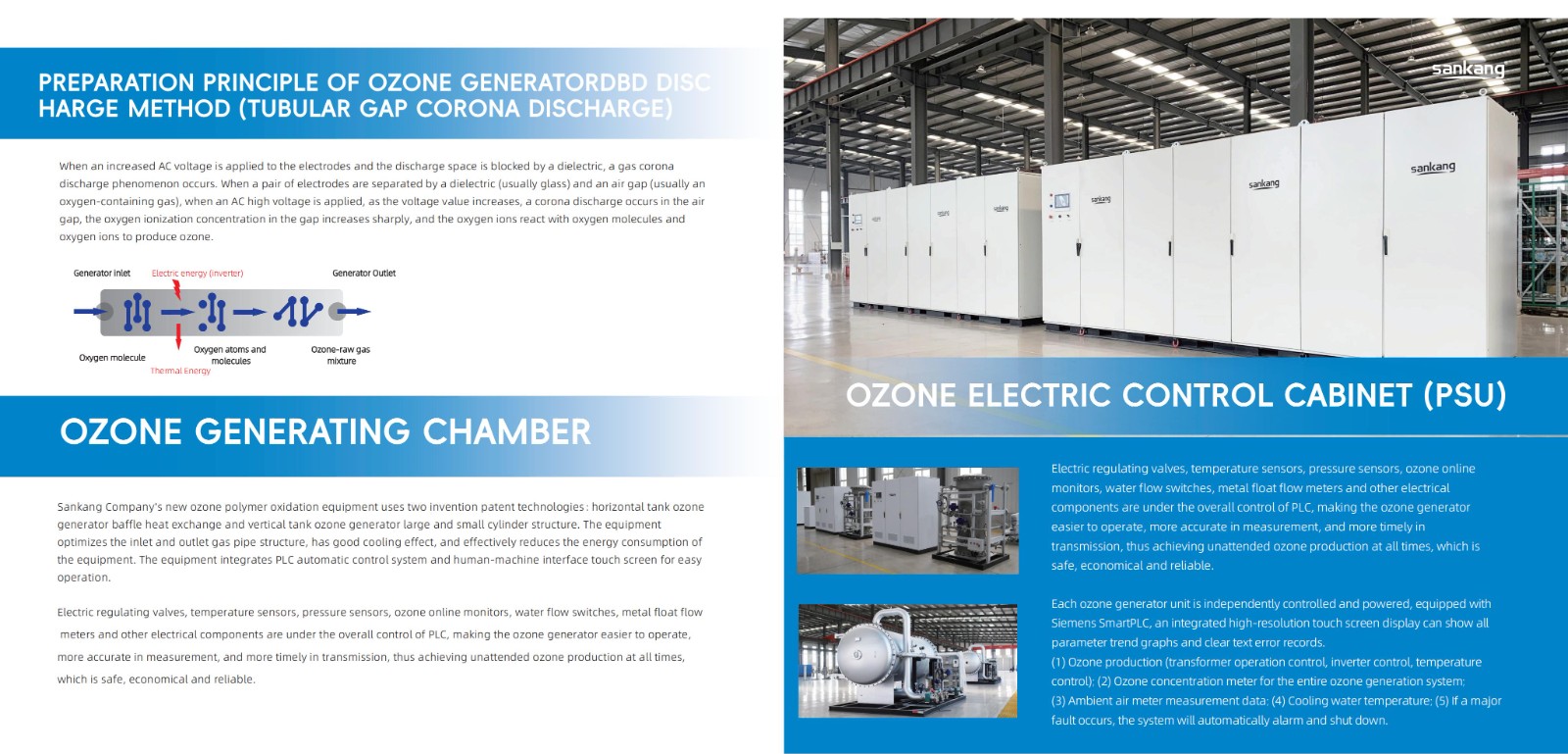

The equipment carries out advanced PLC automatic control and realizes the integration of ozone generation system, air source system, cooling system and control system.

Optimized mechanical design, compact structure, low maintenance workload.

Low harmonic pollution, low power consumption, silent design.

Effective balancing of ejector suction obstruction.

Highly efficient and energy-saving, ozone utilization rate is as high as 95%

The application of IGBT inverter medium-frequency high-voltage power supply can effectively improve ozone generation efficiency, achieve high efficiency and energy saving, and ensure continuous and stable operation.

The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.

In the field of modern industry and environmental protection, ozone generators, as an efficient and environmentally friendly equipment, play a pivotal role. Among them, ozone generators with a production capacity of 35KG/h are core equipment in large-scale water treatment, air purification and food processing industries. This article will explore in depth the technical principles, application fields, equipment advantages and maintenance management of 35KG/h ozone generators, in order to provide valuable reference for practitioners in related industries.

1. Technical Principles

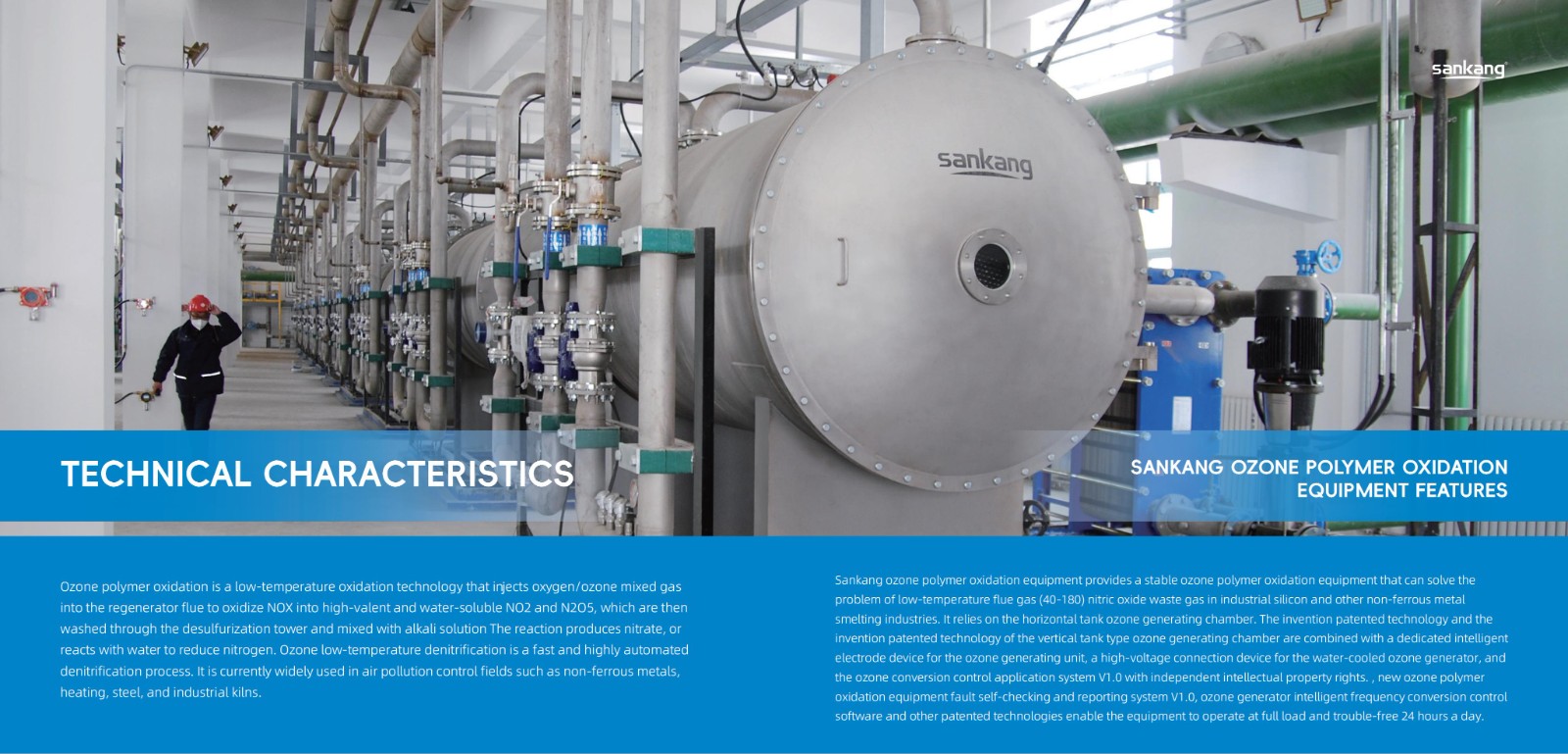

As the name suggests, ozone generators are devices that convert oxygen or air into ozone (O3) through specific technologies. Ozone is a strong oxidant, and its oxidizing ability is second only to fluorine. It can quickly decompose organic matter in water, kill bacteria and viruses, and remove odors. 35KG/h ozone generators usually use high-voltage discharge method (also known as corona discharge method) or ultraviolet radiation method to generate ozone.

High-voltage discharge method is one of the most widely used technologies at present. This method ionizes gas molecules to form high-energy electrons by applying high voltage to a confined space filled with dry oxygen or air. These high-energy electrons collide with oxygen molecules (O2), decomposing them into oxygen atoms (O), which then combine with undecomposed oxygen molecules to form ozone molecules (O3). This process requires precise control of voltage, current, gas flow and cooling system to ensure efficient and stable production of ozone.

The ultraviolet radiation method uses ultraviolet rays of a specific wavelength to irradiate oxygen or air, stimulate electron transitions in oxygen molecules, and form ozone. Although this method has relatively simple equipment, it consumes a lot of energy, and the ozone output is limited by the life and radiation efficiency of the ultraviolet lamp. Therefore, under the large output demand of 35KG/h, it is not as popular as the high-voltage discharge method.

2. Application fields

The 35KG/h ozone generator is widely used in many fields due to its high efficiency and environmental protection characteristics:

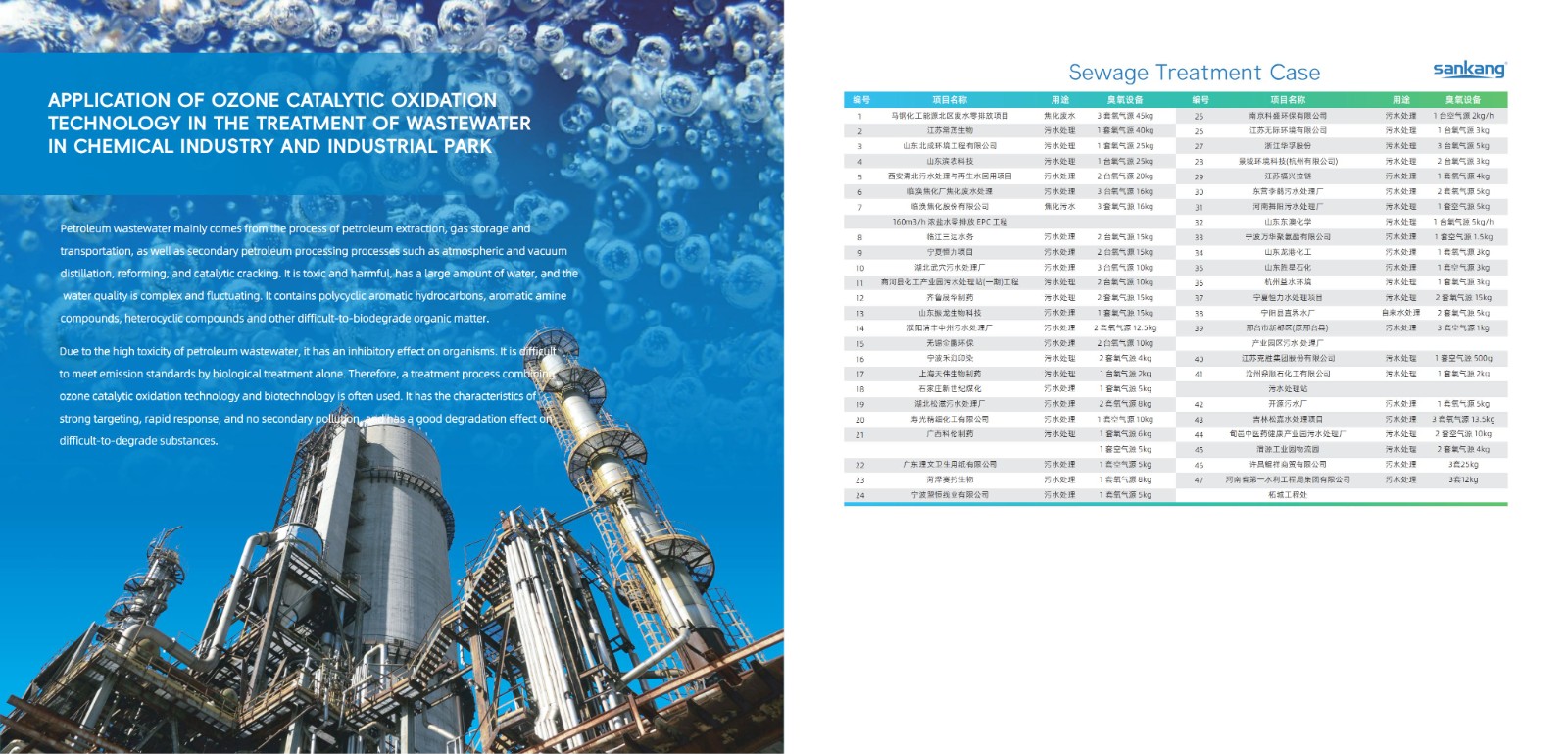

1. **Water treatment**: In water treatment plants, ozone is used as a disinfectant, which can effectively kill bacteria, viruses and parasites in water, while removing color, odor and organic matter in water to improve water quality safety. For large water supply systems, the output of 35KG/h is sufficient to meet daily treatment needs.

2. **Air purification**: In food processing plants, hospitals, pharmaceutical plants and other places with extremely high environmental requirements, ozone generators can be used for air purification to remove bacteria, viruses, molds and harmful chemicals in the air and create a sterile or low-bacteria environment.

3. **Food processing**: Ozone is used as a preservative and disinfectant in food processing, which can extend the shelf life of food and reduce microbial contamination. Especially in fruit and vegetable preservation, meat processing and aquatic product processing, a 35KG/h ozone generator can effectively improve product quality.

4. **Swimming pool water treatment**: Ozone can quickly decompose harmful substances such as chloramines and urea in swimming pool water, reduce the use of disinfectants, and improve water clarity and comfort. For large public swimming pools, a 35KG/h output is an ideal solution.

III. Equipment advantages

1. **High efficiency and energy saving**: Advanced ozone generation technology, combined with an optimized control system, ensures that the equipment operates at high efficiency while reducing energy consumption.

2. **Safe and reliable**: The equipment design complies with international safety standards, and has built-in multiple protection mechanisms, such as overcurrent protection, overvoltage protection, short-circuit protection, etc., to ensure safe operation.

3. **Intelligent management**: Remote monitoring and intelligent control are achieved through PLC or DCS systems, which allows users to grasp the operating status of the equipment in real time, adjust parameters in time, and improve management efficiency.

4. **Modular design**: Easy to install, maintain and upgrade, and can flexibly configure ozone production according to actual needs to meet the needs of different application scenarios.

IV. Maintenance management

To ensure the long-term stable operation of the 35KG/h ozone generator, regular maintenance management is essential. This includes:

- Regularly check key components such as power lines, cooling systems, gas pipelines, etc. to ensure that there are no looseness, leakage and other problems.

- Regularly clean the electrodes and the inner wall of the reactor to remove dust and sediment to maintain high ozone generation efficiency.

- Regularly check the ozone concentration and output, and adjust the operating parameters according to actual usage.

- Establish detailed maintenance records, record the time, content, replacement parts and other information of each maintenance, so as to facilitate subsequent analysis and troubleshooting.

In summary, the 35KG/h ozone generator has become an indispensable and important equipment in many industries with its high efficiency, environmental protection, wide application field and significant equipment advantages. Through scientific and reasonable maintenance management, its effectiveness can be maximized to contribute to environmental protection and human health.