47kg/h Ozone Generator

In order to ensure the long-term stable operation of the 47kg/h ozone generator, regular maintenance and maintenance are required. Here are some common maintenance measures:

1. **Regular Cleaning**: Regularly clean the discharge room, air circuit system and cooling system to remove accumulated dust and dirt and keep the equipment clean and unblocked.

2. **Check the power supply**: Regularly check the voltage, current and frequency of the power supply system and other parameters to ensure the stability and reliability of the power supply.

3. **Replace consumables**: Replace filters, electrodes and other consumables regularly according to the use of consumables to prevent the performance and life of the equipment from being affected by the aging of consumables.

4. Monitoring ozone concentration: Use an ozone concentration monitor to regularly monitor the ozone output concentration of the equipment to ensure the stability and accuracy of ozone generation.

5. **Professional Training**: Regularly conduct professional training for operators to improve their operation skills and maintenance awareness, and ensure the correct use and effective maintenance of the equipment.

In the field of modern industry and environmental protection, ozone generator plays an increasingly important role as an efficient and environmentally friendly equipment. Among them, the 47kg/h output ozone generator has become a popular product in the market due to its strong ozone generation capacity and a wide range of application scenarios. This article will introduce the principle, structure, application and maintenance of 47kg/h ozone generator in detail, in order to provide reference for practitioners in related fields.

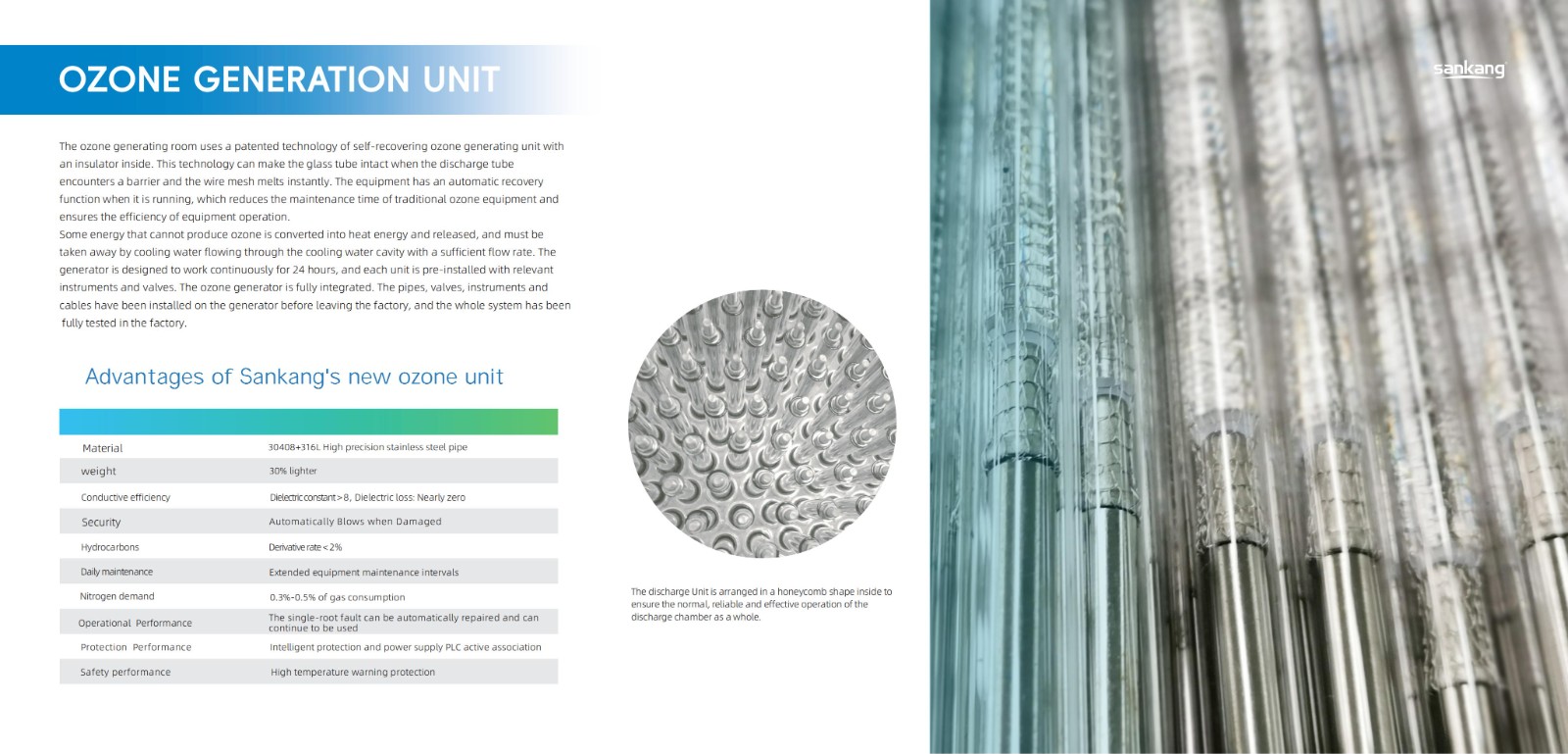

#### First, the basic principle of ozone generator

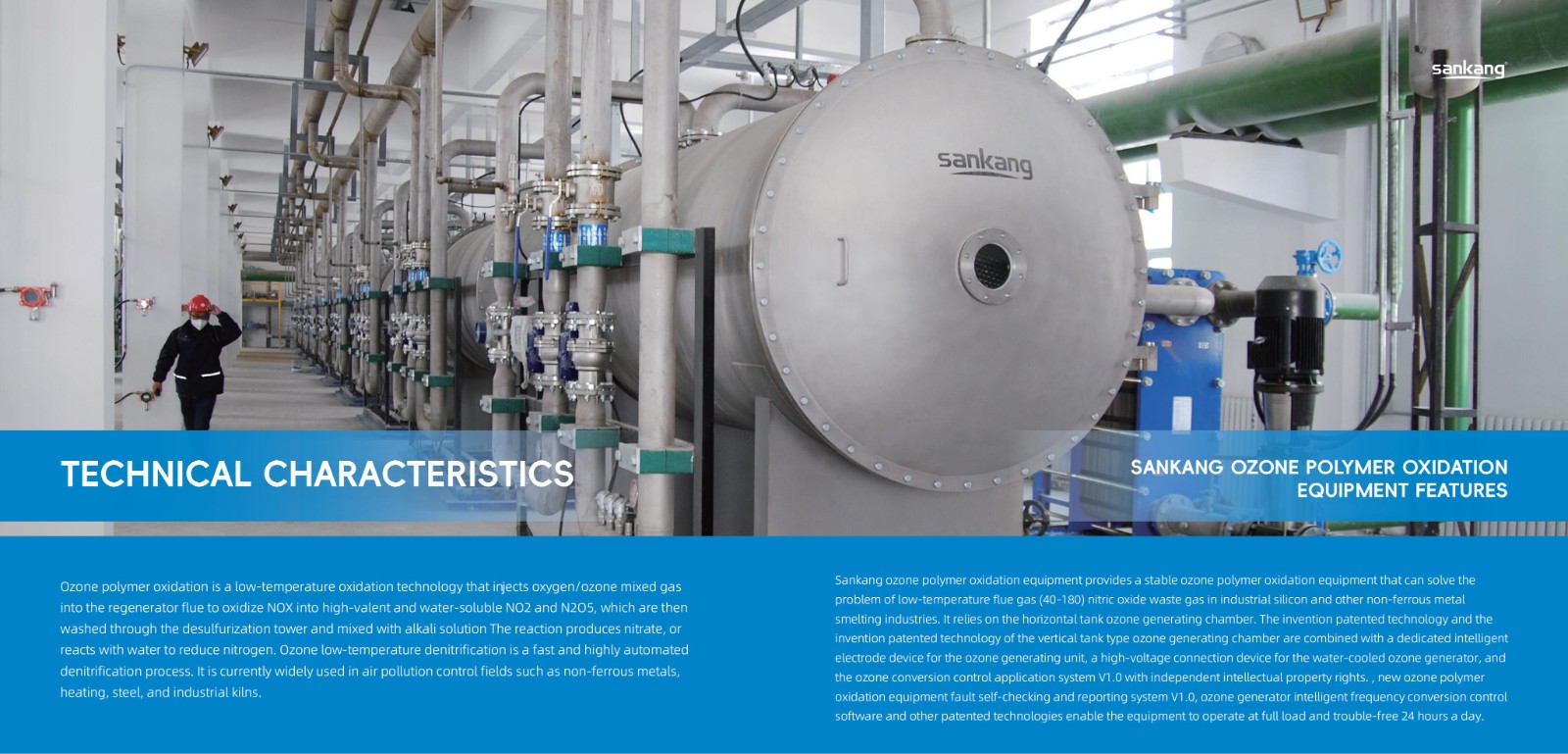

Ozone (O3) is an allotrope of oxygen (O2), which has strong oxidation properties and sterilization and disinfection capabilities. The ozone generator is a device that converts oxygen in the air into ozone through certain technical means. Its core principle mainly involves the corona discharge method, that is, under specific electric field conditions, the oxygen molecules in the air can obtain enough energy to decompose into a single oxygen atom, which then combines with the oxygen molecules to form ozone molecules.

The 47kg/h ozone generator usually uses a high-frequency and high-voltage power supply as the energy source, and efficiently converts the input electrical energy into ozone through a precision-designed discharge chamber. In addition to the generation of ozone, a small amount of heat and by-products such as nitrogen oxides are produced in this process, but modern ozone generators are able to minimize the generation of these by-products through optimized design and control technology, ensuring that the equipment is environmentally friendly and efficient.

#### Second, the structure and composition of the equipment

The structure of the 47kg/h ozone generator is relatively complex, but it is mainly composed of the following key parts:

1. **Power supply system**: It provides high-frequency and high-voltage electrical energy, which is the energy source for ozone generation. Power systems are usually digitally controlled and can accurately adjust the output voltage and current to suit different operating needs.

2. **Discharge chamber**: It is the core component of ozone generation, made of stainless steel or special alloy, and has a discharge electrode and dielectric layer inside. The discharge electrode produces a corona discharge under the action of a high-voltage electric field, which excites oxygen molecules into ozone.

3. Cooling system: Since heat is generated during ozone generation, an effective cooling system is required to keep the equipment running smoothly. Common cooling methods include air cooling and water cooling, and the 47kg/h ozone generator is usually water-cooled to improve cooling efficiency and equipment life.

4. **Air Path System**: Includes components such as air intake, filter, flow meter and air outlet, which are used to feed dry, pure air or oxygen into the discharge chamber and output the generated ozone to the application site.

5. **Control system**: responsible for monitoring the operating status of the equipment, including voltage, current, temperature, ozone concentration and other parameters, and automatically adjusting according to the set value to ensure the stable, safe and efficient operation of the equipment.