60KG/h Ozone Generator

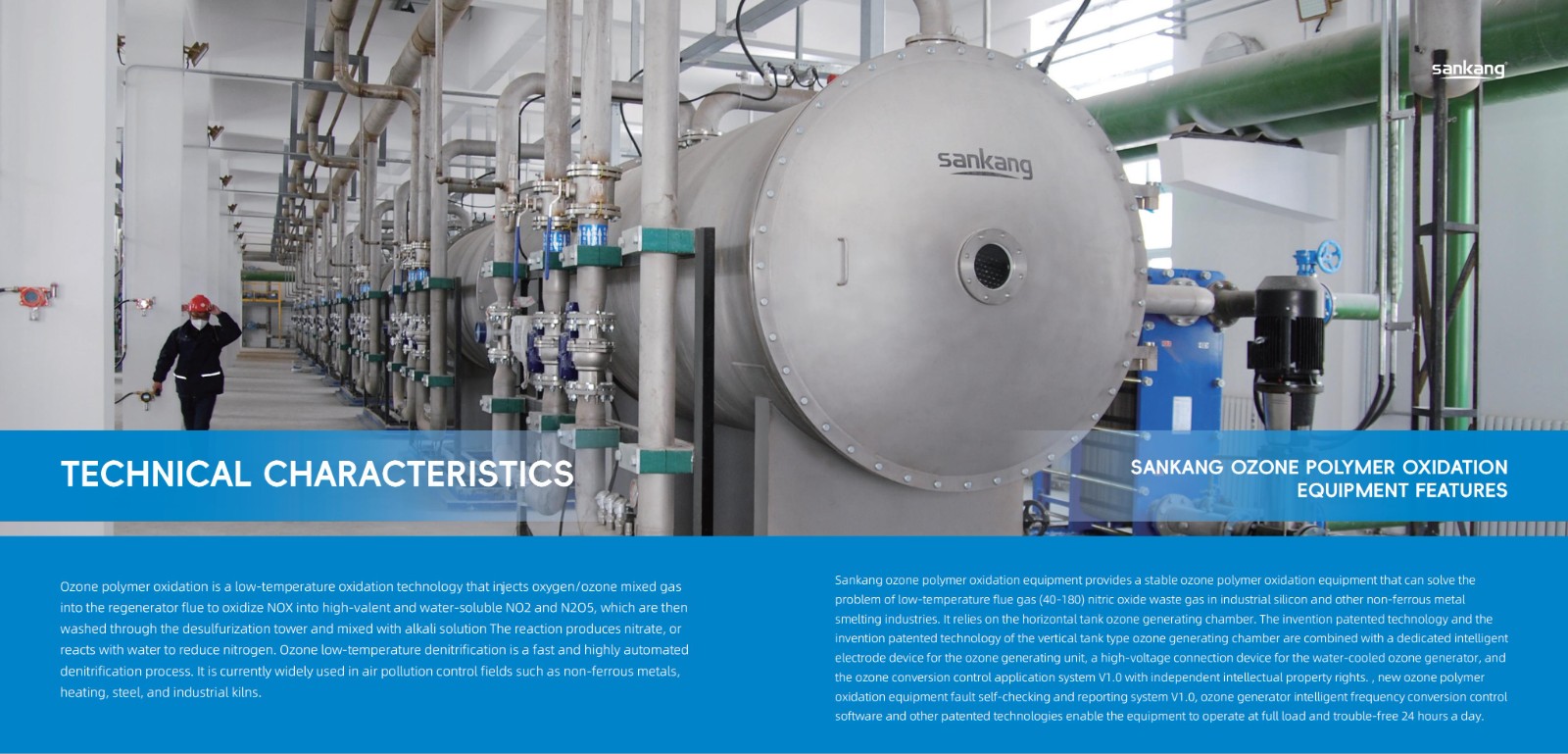

Ozone polymer oxidation flue gas treatment technology is mainly used in the field of flue gas denitration treatment. It is a new environmental protection technology and equipment developed and applied by relevant domestic scientific research institutions and enterprises in recent years for domestic industrial boilers. At present, this technical equipment has been widely used in various industrial boiler projects in steel, petrochemical, non-ferrous metals, light industry and other industries. The main component of NOx in flue gas is NO (volume concentration accounts for 95%). NO is poorly soluble in water and has poor reactivity. As a strong oxidant, ozone can easily oxidize NO into high-valent states NO2, N2O3, N2O5, etc., and dissolve in water to form HNO2 and HNO3. As a clean and strong oxidant, ozone can oxidize NO quickly and effectively. High valence state of nitrogen oxides.

In today's era of rapid industrial development, environmental protection has become an important issue that cannot be ignored. With the country's increasingly stringent requirements for emission standards, all walks of life are actively seeking efficient and environmentally friendly pollution control technologies. Among them, ozone oxidation technology has shown great potential in flue gas denitrification, wastewater treatment and other fields due to its strong oxidation ability and environmental friendliness. This article will introduce in detail a large 60KG/h ozone generator-an industrial ozone generator designed for flue gas denitrification, and explore its working principle, technical characteristics and application advantages.

1. Introduction

Flue gas denitrification is a key measure to reduce the content of nitrogen oxides (NOx) in industrial emissions such as coal-fired power plants and chemical plants. Although traditional methods such as selective catalytic reduction (SCR) and selective non-catalytic reduction (SNCR) have certain effects, they have problems such as high investment costs, complex operation and maintenance, and possible secondary pollution. In contrast, ozone oxidation technology, as an emerging and efficient denitrification method, generates water-soluble nitrates through the reaction of ozone and NOx, which are then removed by a wet scrubbing system, achieving the goal of efficient and low-cost denitrification. All of this is inseparable from the support of the core equipment - large-scale industrial ozone generator.

2. Equipment Overview

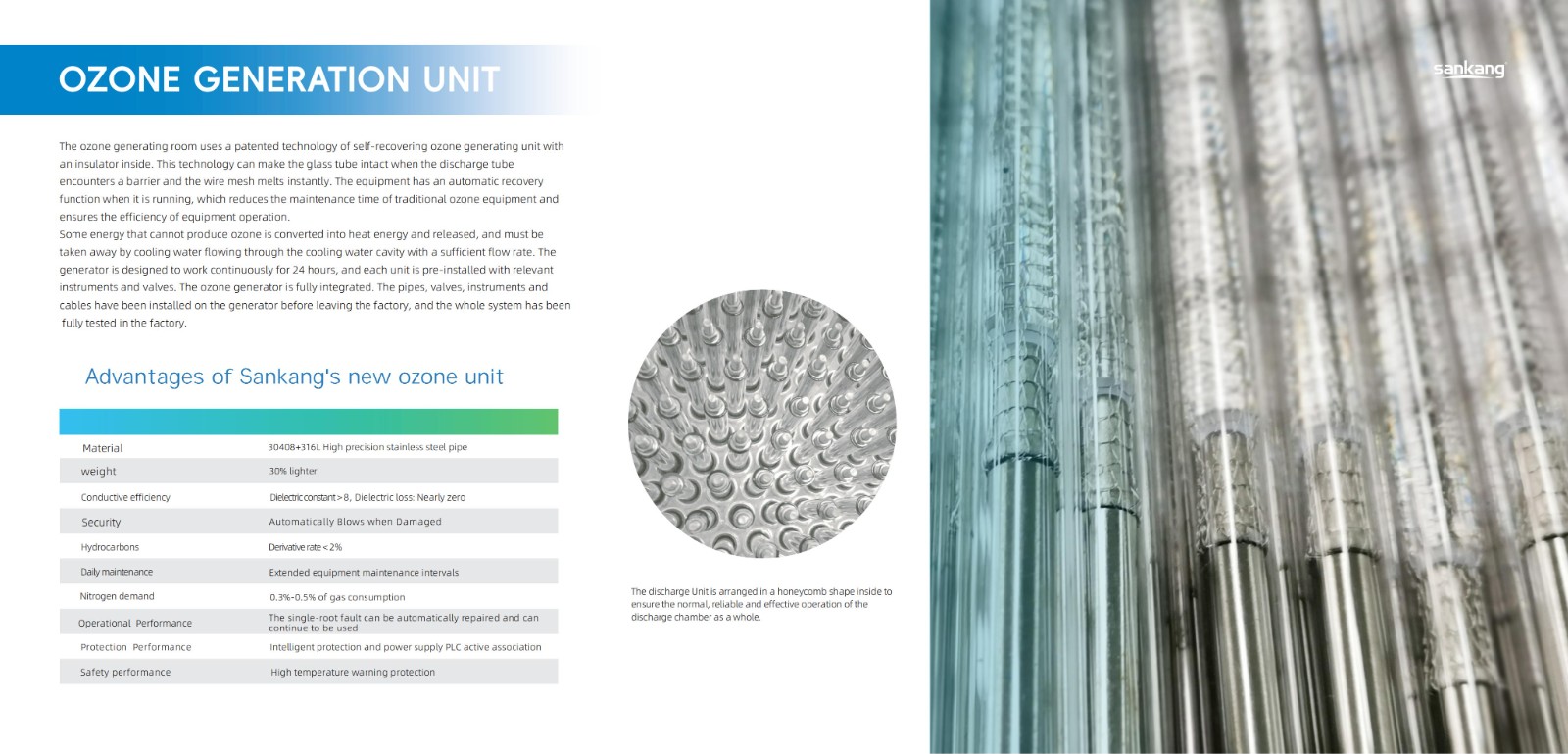

This 60KG/h ozone generator is specially designed for flue gas denitrification. It adopts advanced dielectric barrier discharge (DBD) technology and can stably produce a large amount of ozone with high energy efficiency. Its processing capacity reaches 60 kilograms per hour, which is enough to meet the denitrification needs of large and medium-sized industrial facilities. The equipment has a compact structure and a small footprint, which is convenient for on-site installation and commissioning. In addition, the ozone generator is equipped with an intelligent control system, which can automatically adjust the ozone output according to the actual flue gas flow and NOx concentration, ensuring the denitrification efficiency while maximizing the utilization of energy.

3. Working principle and technical features

1. Working principle: The ozone generator uses a high-voltage electric field to act on oxygen-containing gas (usually air or oxygen) to ionize and excite gas molecules to form ozone molecules (O3). During the flue gas denitrification process, the generated ozone reacts quickly with NOx in the flue gas to generate nitrate ions (NO3-) and nitrite ions (NO2-), which are then absorbed and removed by water in the wet scrubber.

2. Technical features:

- High efficiency: Adopting high-efficiency DBD technology, the ozone generation efficiency is high and the energy consumption is low.

- Strong stability: The equipment is designed with a cooling system and an automatic protection mechanism to ensure long-term stable operation.

- Intelligent control: Integrated intelligent control system to achieve remote monitoring and automatic adjustment, easy to operate.

- Environmental protection and safety: The entire denitrification process does not produce secondary pollution, which meets environmental protection requirements.