80kg Large Ozone Generator

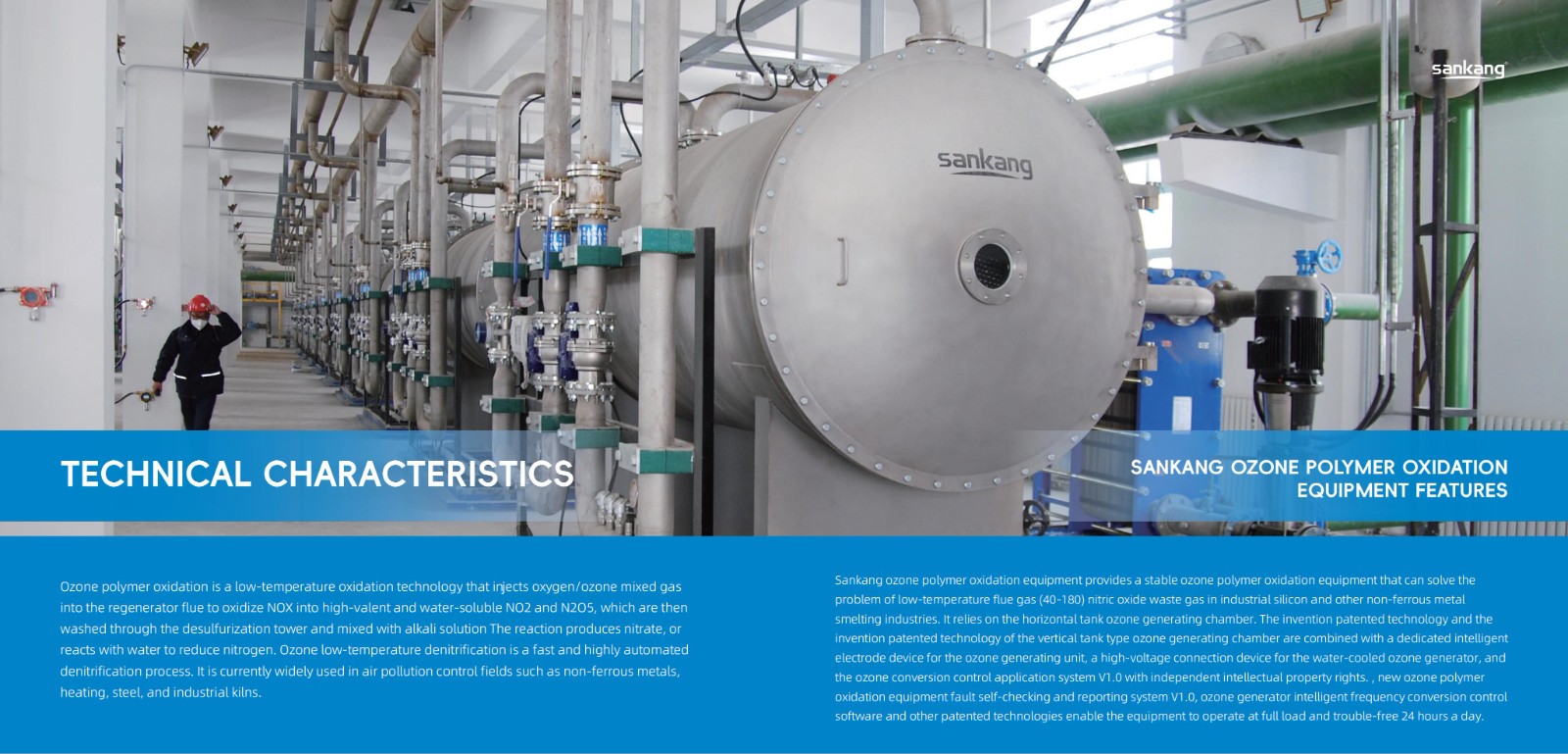

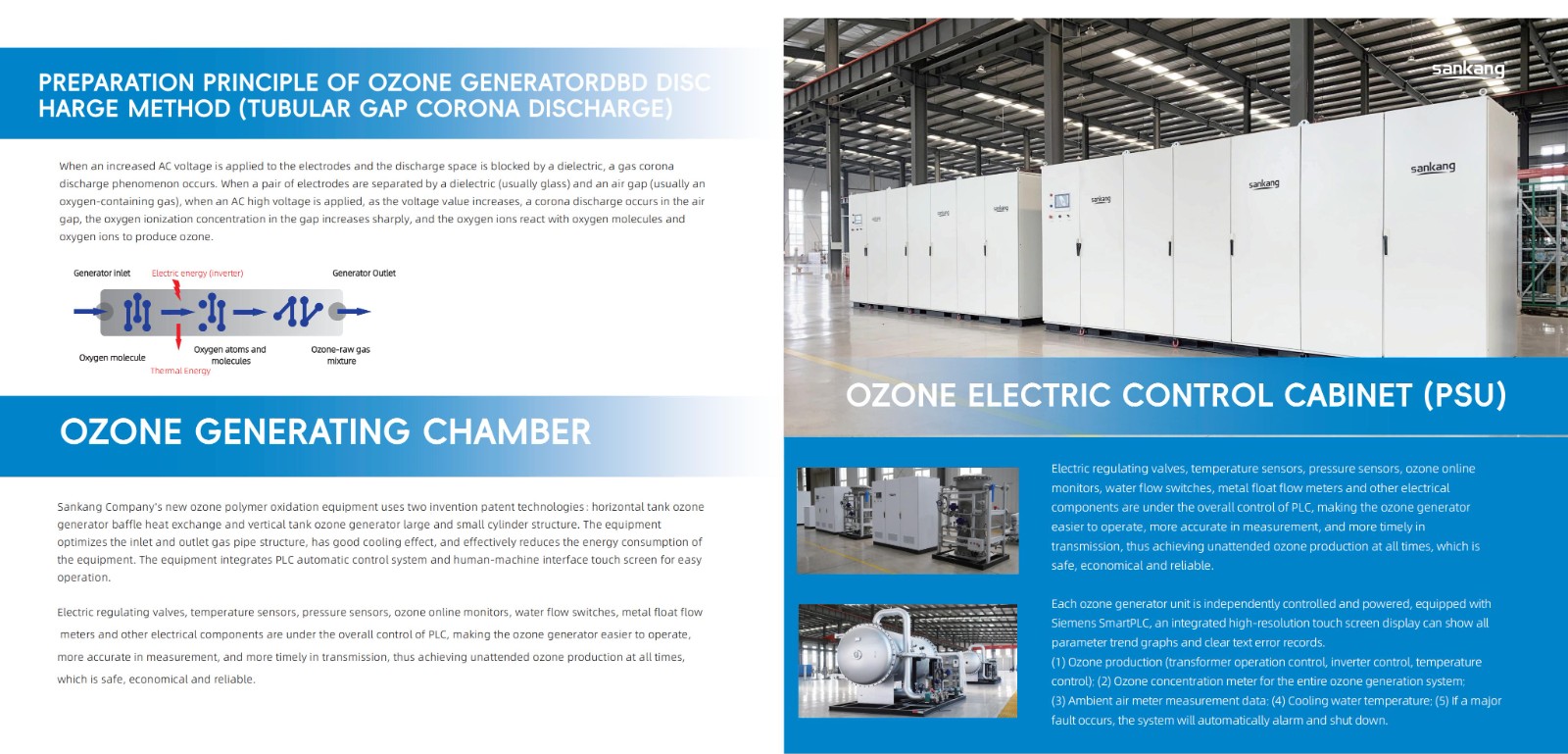

Sankang's new ozone polymer oxidation equipment applies two patented invention technologies: horizontal tank-type ozone generating chamber baffle plate heat exchange and vertical tank-type ozone generating chamber large and small cylinder structure. The equipment optimizes the structure of the air inlet and outlet ducts, has good cooling effect, and effectively reduces the energy consumption of the equipment. The equipment integrates a PLC automatic control system and a human-machine interface touch screen, making it easy to operate.

Electrical control valves, temperature sensors, pressure sensors, ozone online monitors, water flow switches, metal float flowmeters and other electrical components are under the overall control of PLC, making the ozone generator more convenient to operate, more accurate in measurement, and more timely in transmission, realizing ozone The whole production period is unattended, safe, economical and reliable.

In the field of modern industrial production and environmental purification, ozone generator plays a pivotal role as an efficient and environmentally friendly equipment. Among them, industrial ozone generators with a capacity of 80kg and larger, such as 80kg, 100kg, 120kg, 150kg and other specifications, are favored for their strong ozone generation capabilities and a wide range of application scenarios. This article will deeply discuss the characteristics, working principles, application fields, selection and maintenance of this series of large-scale ozone generators, in order to provide valuable reference for related industries.

1. Characteristics of large ozone generators

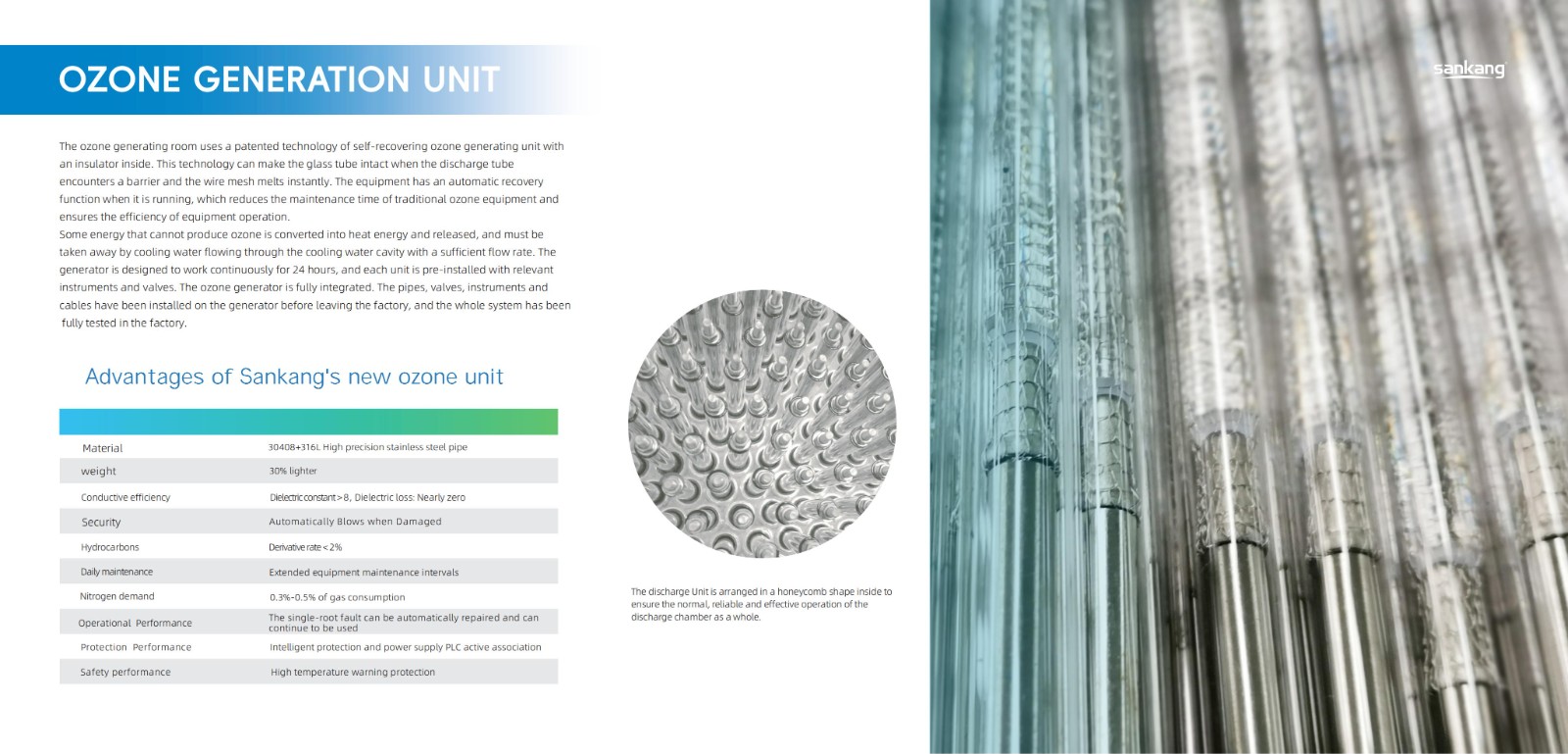

The most striking feature of large-scale ozone generators, especially those of 80 kg and above, is their efficient ozone generation and stable operation. These devices typically use advanced ozone generation technologies, such as high-voltage discharge, ultraviolet radiation, or electrolysis, to produce large amounts of ozone in a short period of time. At the same time, in order to ensure the long-term stable operation of the equipment, the design of large-scale ozone generators often pays attention to the selection of materials and the optimization of manufacturing processes to ensure that the equipment can still maintain good working conditions under harsh working conditions.

In addition, the large ozone generator also has the characteristics of intelligent control. By integrating advanced sensors and control systems, the equipment can monitor key parameters such as ozone concentration and gas flow in real time, and automatically adjust the amount of ozone produced according to actual needs to achieve energy-efficient operation.

Second, the working principle

The working principle of large ozone generators is mainly based on the chemical synthesis process of ozone. In the high-voltage discharge method, for example, when a high-voltage electric field acts on an oxygen-containing gas, gas molecules are ionized into ions and electrons in a high-energy state. These high-energy particles collide and excite further in an electric field to form ozone molecules. Ultraviolet radiation and electrolysis also promote the conversion of oxygen molecules to ozone molecules through similar mechanisms.

It is important to note that ozone is a strong oxidizing agent with extremely high reactivity. Therefore, in the process of ozone generation, it is necessary to strictly control the reaction conditions and equipment parameters to avoid excessive decomposition of ozone or reaction with other substances, which will affect the purity and yield of ozone.

Third, the field of application

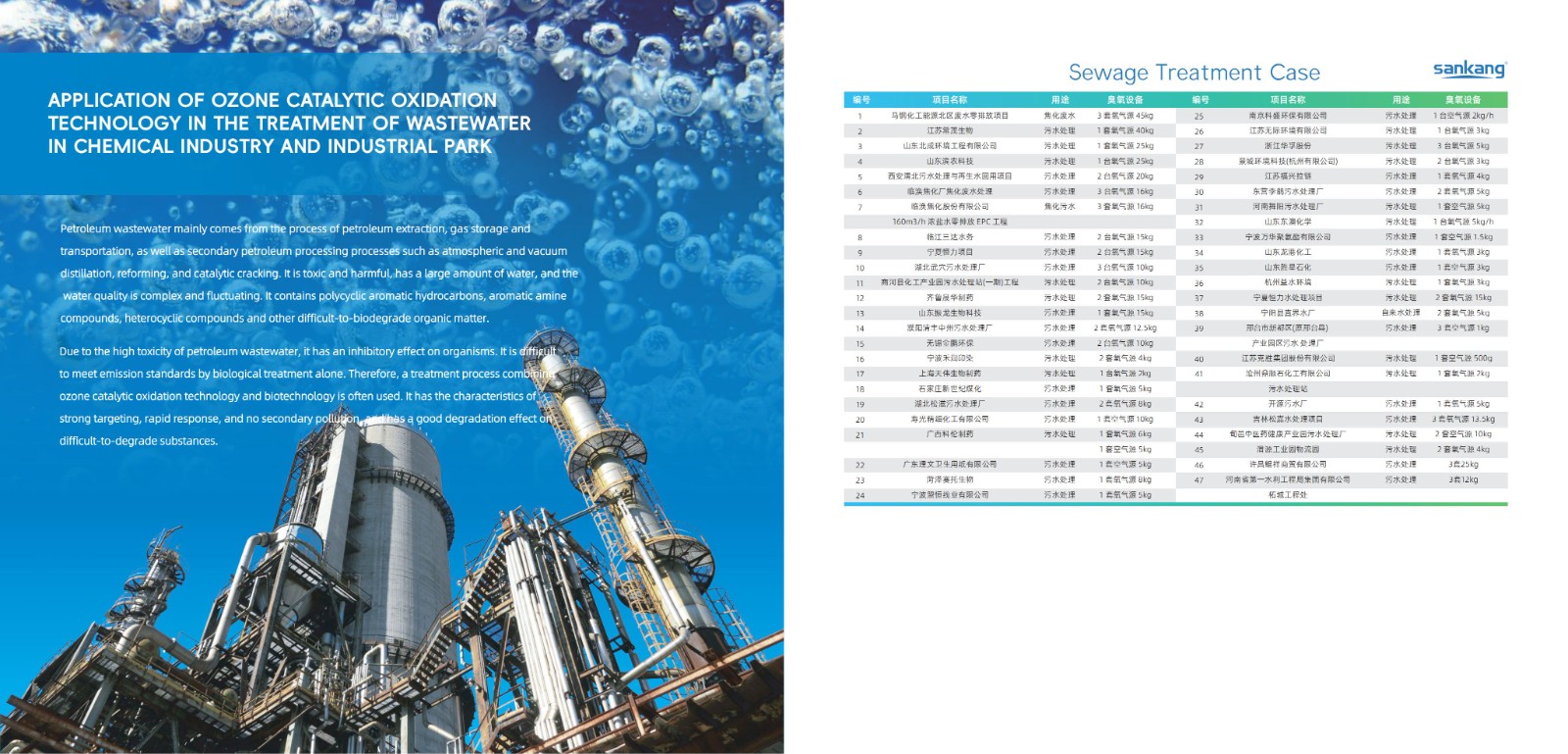

Large ozone generators have a wide range of applications in a variety of fields. In the field of environmental protection, they are used for wastewater treatment, air purification and deodorization of exhaust gases. The strong oxidizing properties of ozone can effectively improve water quality and air quality by destroying the structure of organic matter and decomposing it into harmless substances.