87kg/h Ozone Generator

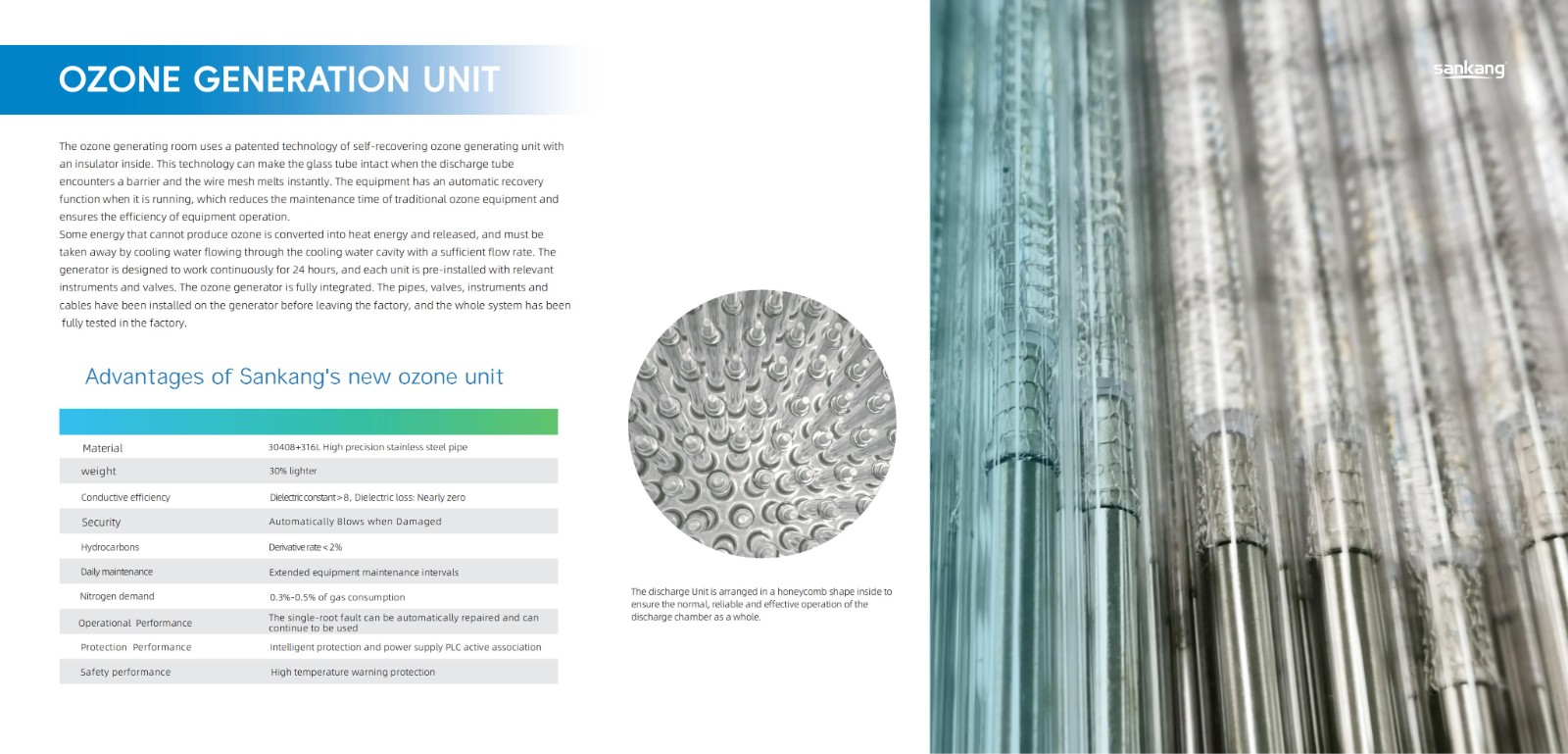

1. High efficiency: The 87kg/h ozone generator adopts advanced discharge technology and optimized gas flow channel design to ensure high ozone yield and conversion rate to meet the needs of large-scale applications.

2. Stability: Through precise control of power output, optimization of the cooling system, and the use of high-quality materials, the long-term stable operation of the equipment is ensured and the failure rate is reduced.

3. Intelligent: Modern 87kg/h ozone generators are usually equipped with intelligent control systems, which can monitor key parameters such as ozone concentration and gas flow in real time, and automatically adjust them according to the set value, improving operation convenience and energy efficiency.

4. Environmental protection and energy saving: Adopt high-efficiency and energy-saving technology to reduce energy consumption, and at the same time, ozone as a green disinfectant, no residue, no pollution, in line with environmental protection requirements.

In the field of modern industry and environmental protection, ozone generators play a vital role as an efficient and environmentally friendly equipment. Among them, the ozone generator with a capacity of 87kg/h is a leader in large-scale water treatment, air purification, disinfection and sterilization applications. This article will deeply discuss the technical principle, application field, performance characteristics and maintenance of 87kg/h ozone generator, in order to provide valuable reference for practitioners in related industries.

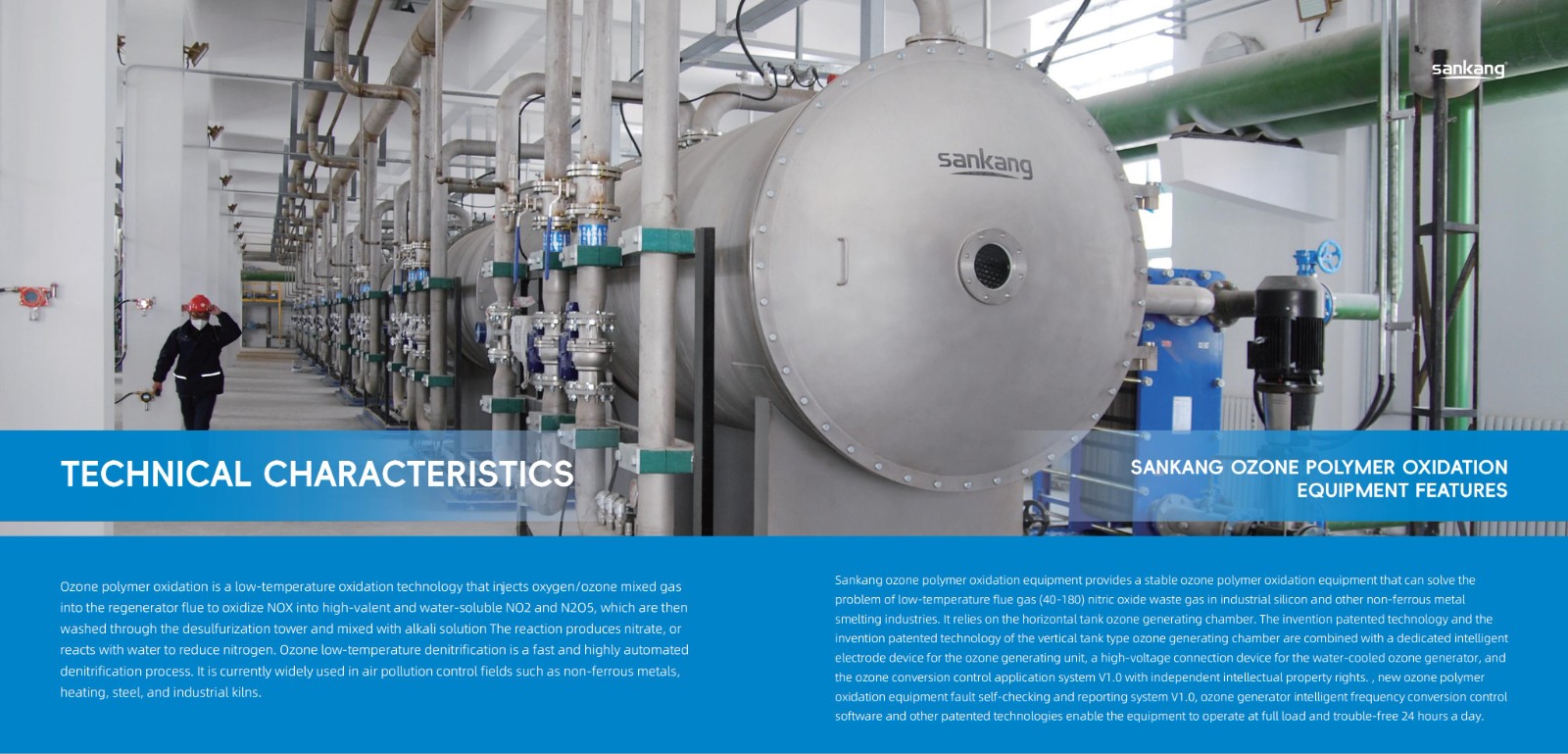

First, the technical principle

The working principle of the ozone generator is based on the corona discharge method, that is, dry, pure oxygen or air is passed through a high-voltage electric field, so that the oxygen molecules are decomposed into individual oxygen atoms under the action of the electric field energy, and then combined with the undecomposed oxygen molecules to form ozone (O3). The 87kg/h ozone generator usually uses a high-frequency and high-voltage power supply, and the precision-designed discharge chamber structure ensures efficient and stable ozone generation. In this process, the electrode material in the discharge chamber, gas flow control, cooling system and other factors have a significant impact on ozone production and purity.

Second, the field of application

1. Water treatment: 87kg/h ozone generator is widely used in the field of water treatment, including swimming pool water purification, drinking water disinfection, industrial wastewater treatment, etc. The strong oxidizing properties of ozone effectively remove organic matter, bacteria, viruses and heavy metal ions in water, and improve water quality safety.

2. Air purification: In food processing plants, hospitals, pharmaceutical factories and other places with extremely high requirements for environmental hygiene, the 87kg/h ozone generator can be used for air purification, by decomposing harmful substances in the air, such as formaldehyde, benzene, bacteria, viruses, etc., to create a cleaner and healthier indoor environment.

3. Disinfection and sterilization: Ozone's strong oxidation and broad-spectrum sterilization make it an ideal alternative to traditional chemical disinfectants. In the fields of cold storage disinfection, fruit and vegetable preservation, medical equipment disinfection, etc., the 87kg/h ozone generator can efficiently kill microorganisms, prolong the shelf life of food, and ensure public health and safety.

In order to ensure the continuous and efficient operation of the 87kg/h ozone generator, regular maintenance is essential. This includes, but is not limited to:

- Regularly inspect power cords and electrical components to ensure that there are no breakage or looseness.

- Clean the discharge chamber and gas filter to prevent the accumulation of dust and impurities from affecting the ozone generation efficiency.

- Inspect the cooling system to ensure that the cooling water is flowing smoothly and to prevent overheating from damaging the equipment.

- Regularly calibrate ozone concentrations and gas flow rates to ensure a stable output.

- Establish a sound maintenance record, track the operation status of the equipment, and find and solve problems in a timely manner.