8kg Ozone Generator

The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.

The ozone system uses water cooling technology to maintain efficient and stable ozone production.

The discharge tube adopts advanced high borosilicate tube discharge technology.

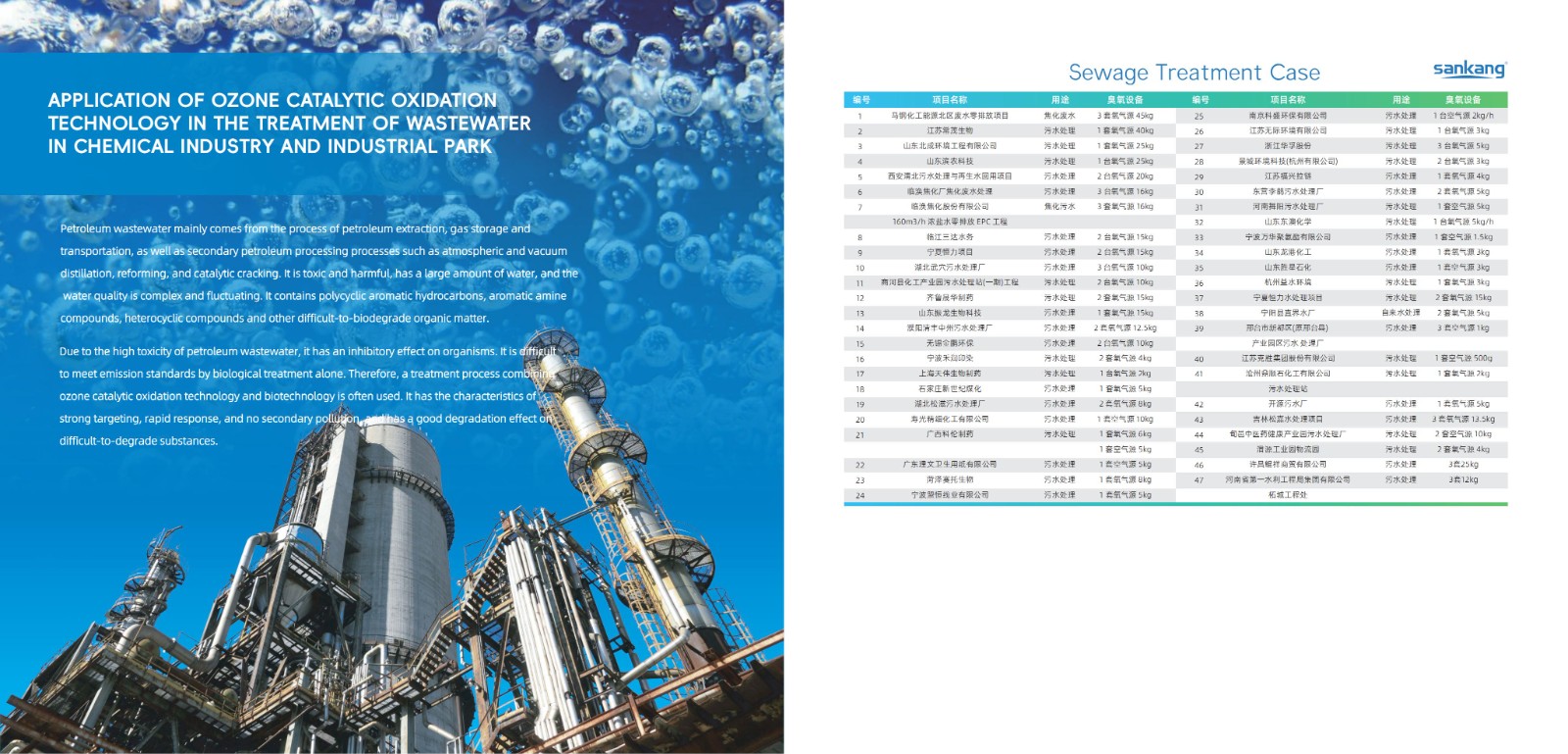

In modern water treatment processes, ozone generators have become an important water treatment equipment with their efficient oxidation capacity and wide application fields. This article will introduce in detail the application of 8kg ozone generators in water treatment, including its working principle, system configuration, technical parameters and specific application scenarios.

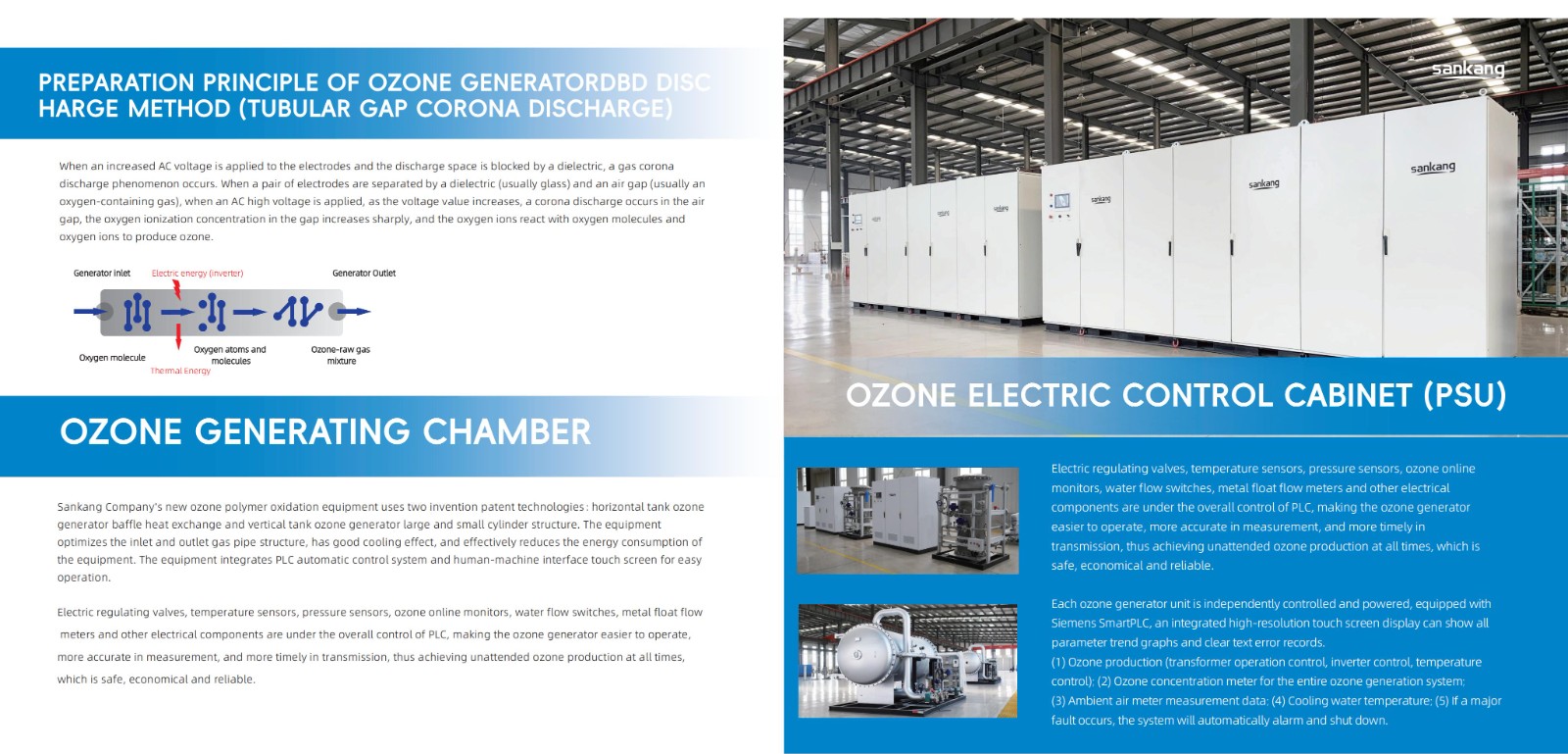

1. Working principle of ozone generator

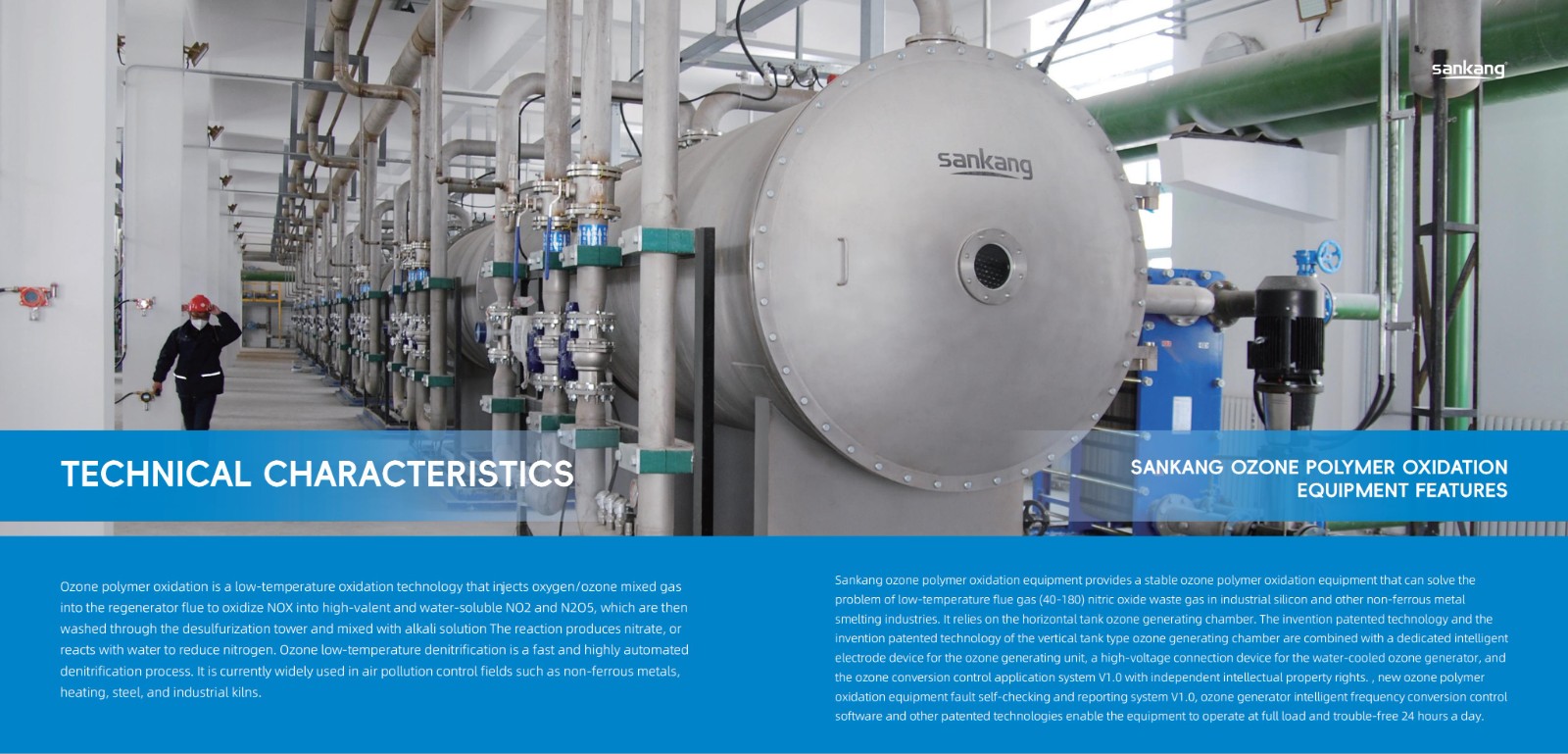

Ozone generator is a device that uses a high-voltage electric field to convert oxygen in the air into ozone through discharge. Ozone (O3) is a strong oxidant composed of three oxygen atoms and has a strong oxidation capacity. In water, ozone can oxidize and decompose harmful substances such as organic matter, heavy metal ions, bacteria, viruses, etc. in water, thereby achieving the purpose of purifying water quality. This conversion process not only depends on the design and performance of the ozone generator, but also requires a stable air source and an efficient cooling system.

2. System configuration of 8kg ozone generator

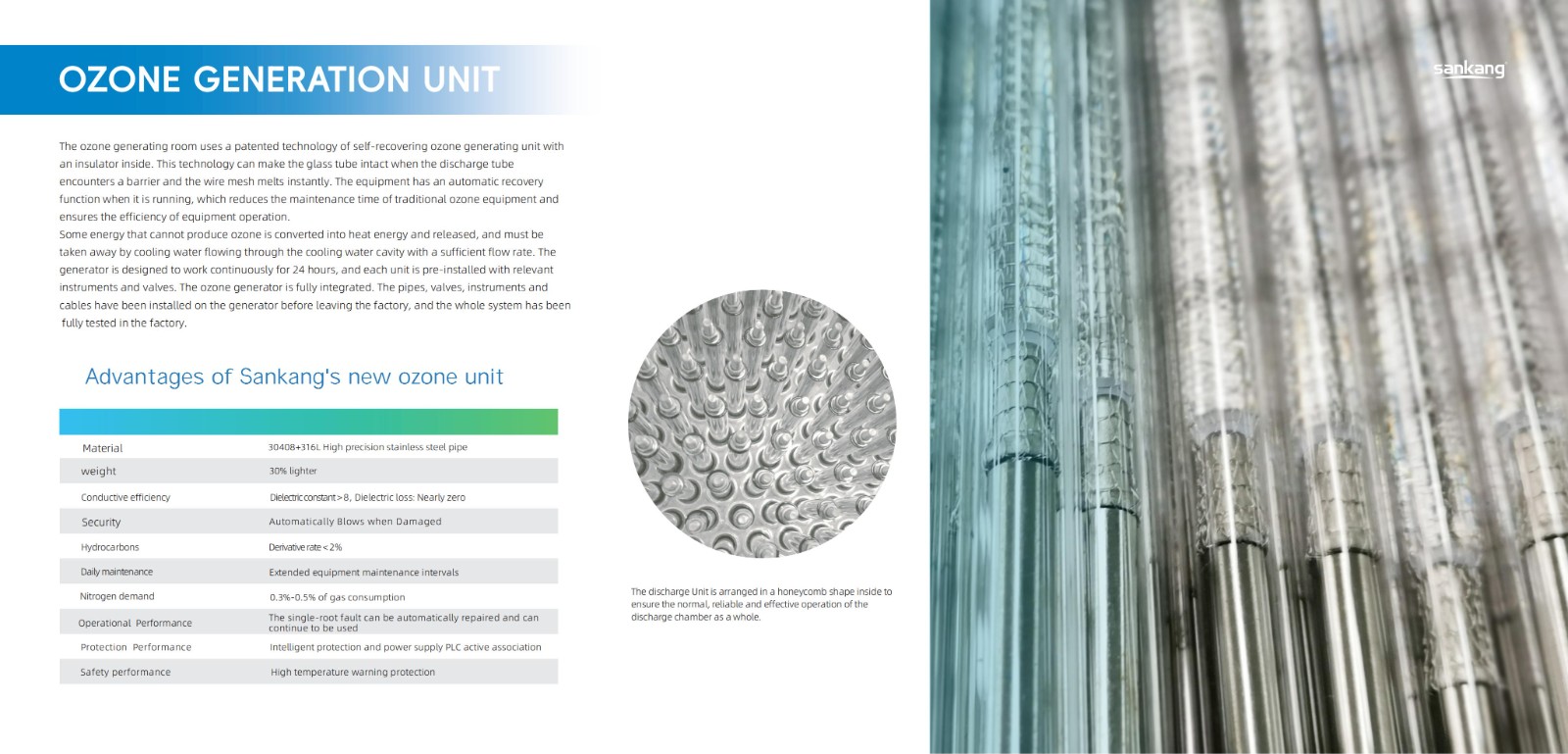

A complete 8kg ozone generator system usually consists of an ozone generation system, an air source treatment system, a circulating water cooling system, etc.

The ozone generation system includes the ozone generator body, which generally adopts a honeycomb structure, with a rated ozone output of 8kg/h, an input power of 380V/50Hz/3ph, and a rated power between 40-42KW. The system is equipped with necessary control valves such as pressure reducing valves, switch valves, safety valves, and monitoring equipment such as pressure transmitters and temperature transmitters to ensure the stability and safety of ozone generation.

The air source processing system includes air compressors, gas storage tanks, refrigerated dryers, adsorption dryers and other equipment. These equipment are responsible for providing clean, dry and stable air sources to meet the needs of ozone generators. Among them, the air compressor provides sufficient compressed air, the gas storage tank is used to store and adjust the air pressure, and the dryer is used to remove moisture and impurities from the air.

The circulating water cooling system includes internal circulation water pumps, chillers, cooling water tanks and other equipment. The ozone generator will generate a lot of heat energy during the discharge process, and the heat needs to be taken away in time through the cooling water system to maintain the normal operation of the equipment. The cooling water flows through the ozone generator tank through the cooling water cavity, takes away the generated heat, and then returns to the chiller for cooling, forming a closed-loop cooling system.

3. Technical parameters of 8kg ozone generator

The main technical parameters of the 8kg ozone generator include power requirements, system power consumption, distribution capacity, circulating cooling water volume, etc. The power supply requirement is 380V/50Hz/3ph, three-phase five-wire system, system power consumption is about 260KWh, and distribution capacity is 300KVA. The circulating cooling water volume is between 8-10m3/h, and the cooling water filling volume is about 0.5 tons.

The ozone output of the ozone generator can be adjusted between 10-100%, the unit ozone power consumption is about 42KWh/kgO3 (cooling water 25℃), and the ozone concentration is 80-100mg/L (cooling water 25℃). These parameters can be adjusted and optimized according to actual application requirements to achieve the best treatment effect.