320g Ozone Generator

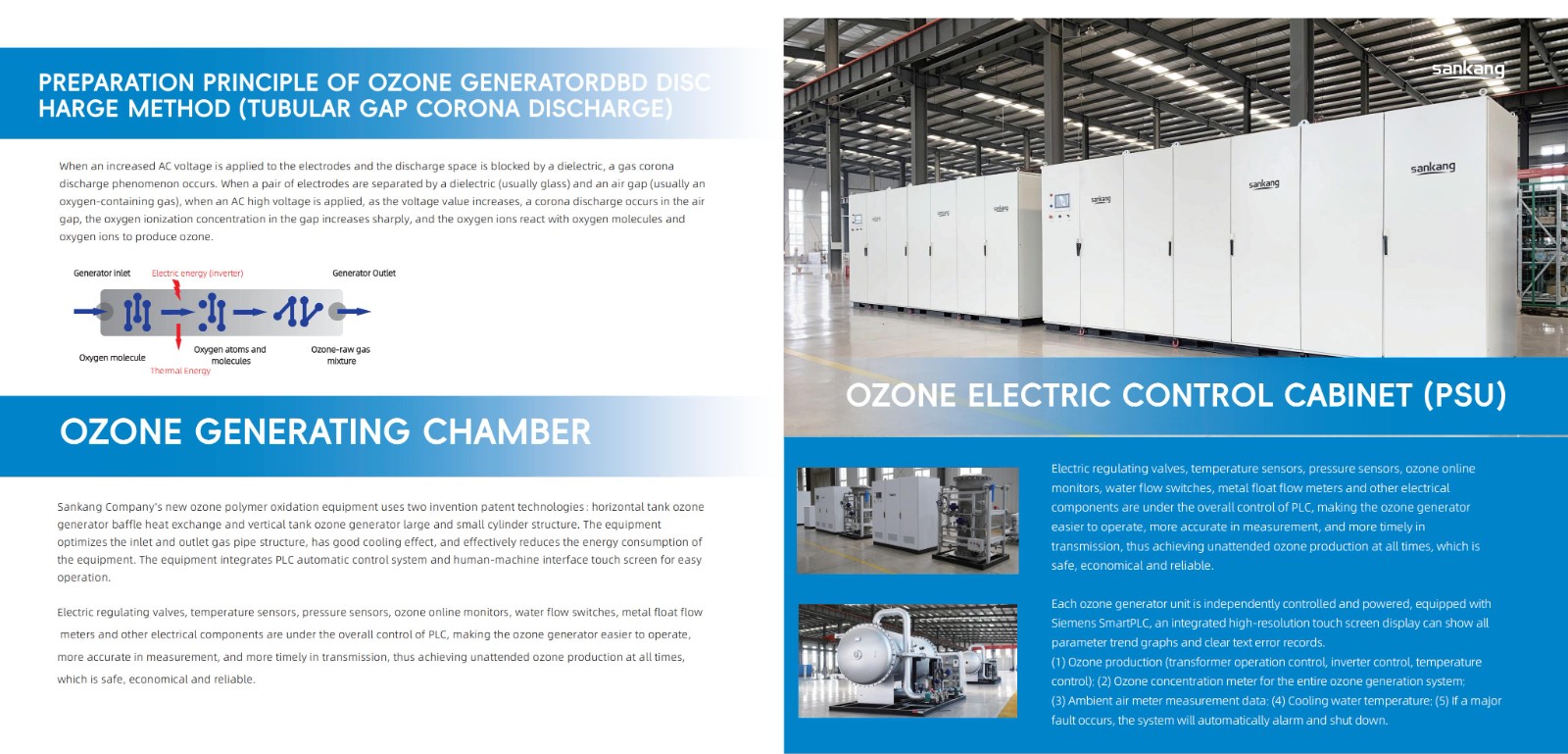

The application of IGBT inverter medium-frequency high-voltage power supply can effectively improve ozone generation

efficiency, achieve high efficiency and energy saving, and ensure continuous and stable operation.The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.The ozone system uses water cooling technology to maintain efficient and stable ozone production.The discharge tube adopts advanced high borosilicate tube discharge technology.The vacuum thermal regeneration system provides high-quality air to the generating unit and increases ozone concentration.The equipment works in negative pressure mode, which effectively avoids ozone leakage and is safe and reliable.The equipment carries out advanced PLC automatic control and realizes the integration of ozone generation system, air source system, cooling system and control system.Optimized mechanical

design, compact structure, low maintenance workload .Low harmonic pollution, low power consumption, silent design.Effective balancing of ejector suction obstruction.

Industrial ozone generator Water treatment ozone generator High-quality ozone generator

In the field of modern industry and environmental protection, ozone generators, as an efficient and environmentally friendly equipment, are playing an increasingly important role. In particular, industrial ozone generators, water treatment ozone generators and high-quality ozone generators have become an indispensable part of many industries with their unique advantages. This article will introduce these three ozone generators in detail, explore their working principles, application fields and the importance of choosing high-quality ozone generators.

1. Industrial ozone generator: a model of high efficiency and stability

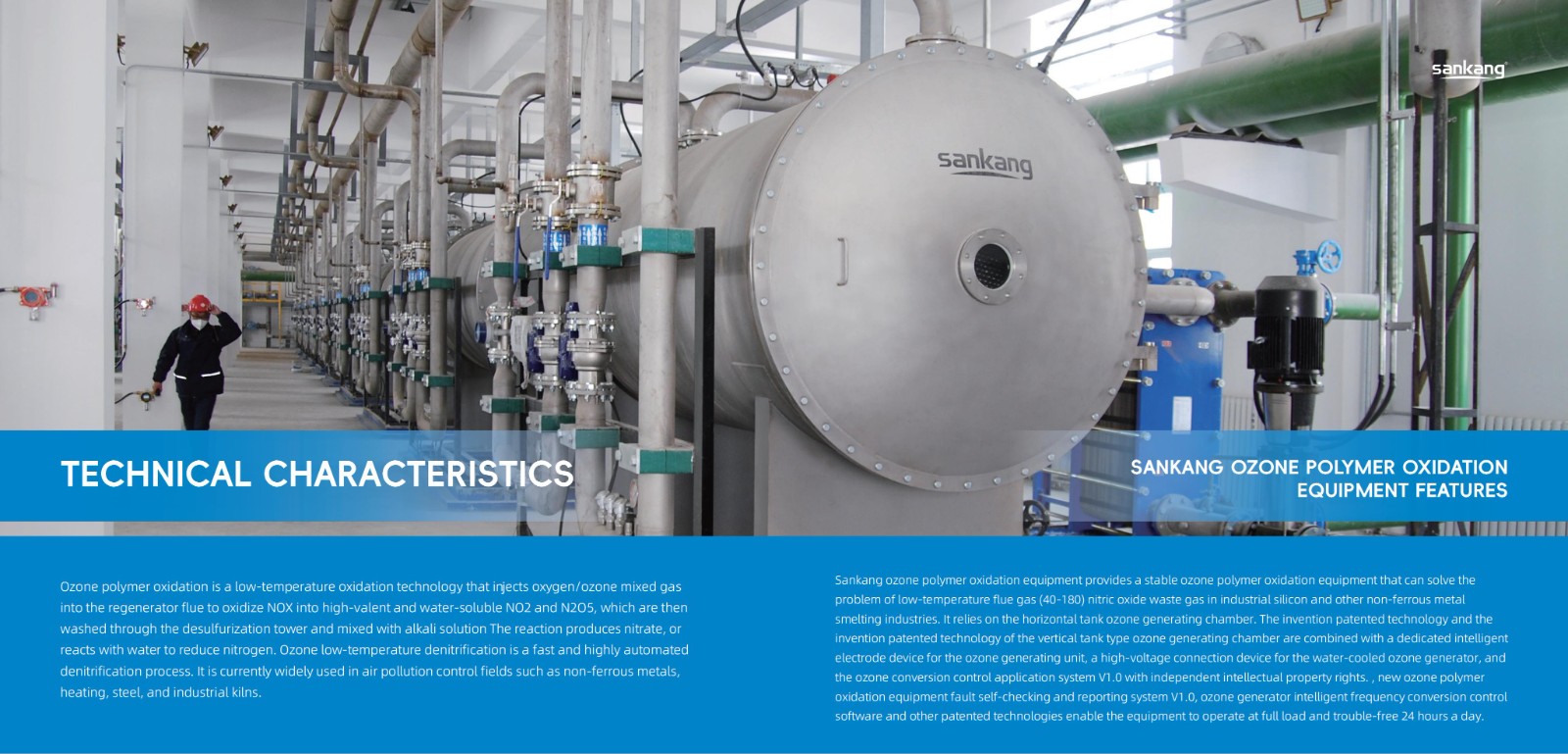

Industrial ozone generators are mainly used for large-scale air or water purification. It uses a high-voltage electric field to ionize oxygen or air molecules, decompose them into oxygen atoms, and then combine with oxygen molecules to form ozone (O3). This process is not only efficient, but also can continuously and stably produce a large amount of ozone. Industrial ozone generators are widely used in food processing, pharmaceuticals, chemicals, textiles and other fields for disinfection, deodorization, bleaching and other processes.

In the food processing industry, industrial ozone generators can effectively kill microorganisms on the surface of food and extend the shelf life of food. In the pharmaceutical industry, the strong oxidizing property of ozone can destroy the cell structure of pathogens such as bacteria and viruses to meet the requirements of aseptic production. In addition, industrial ozone generators can also be used in chemical production to remove harmful substances in exhaust gas and protect the environment.

2. Water treatment ozone generator: Green Guardian of Water Quality

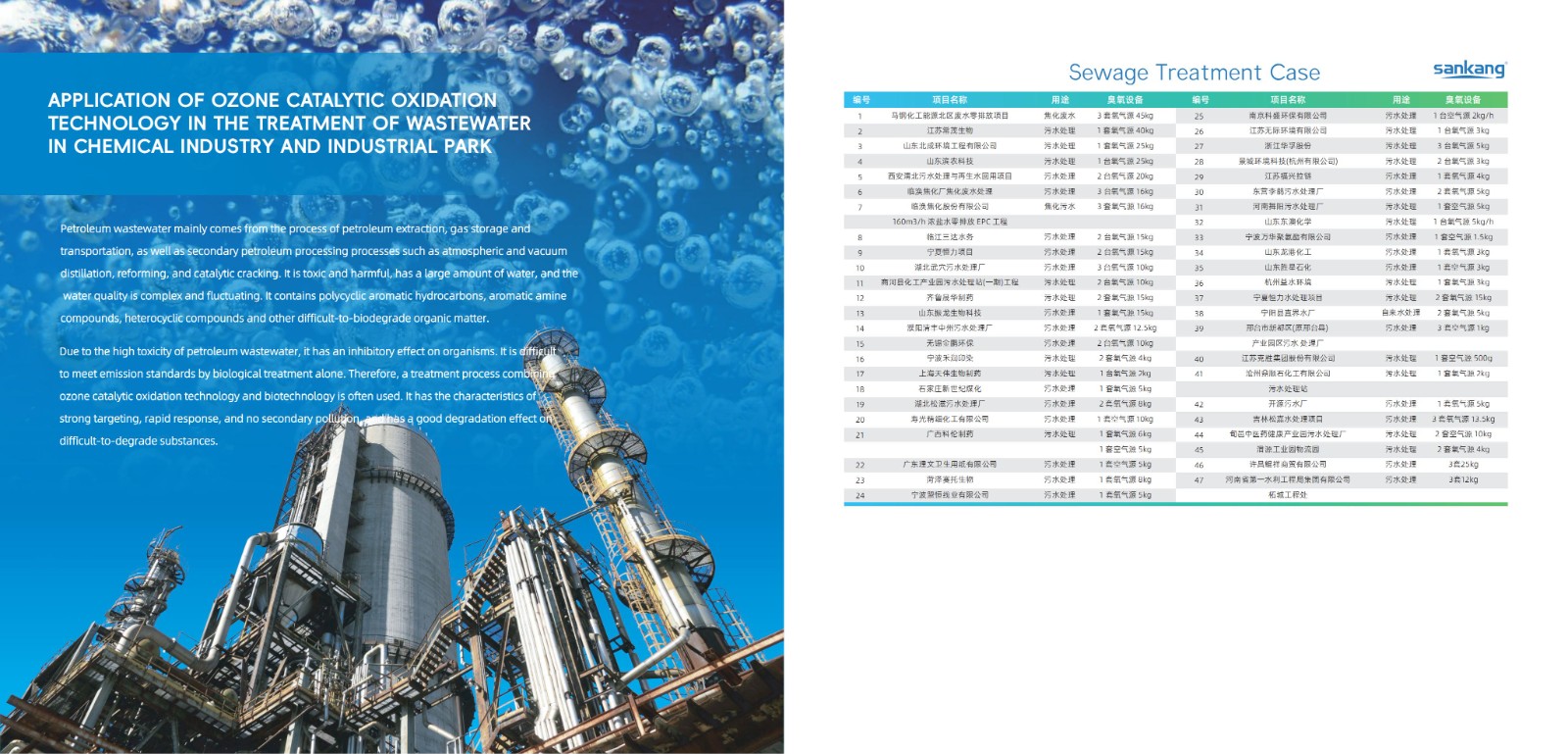

Water treatment ozone generator is an ozone generating device specially designed for water purification. It injects ozone into the water and uses the strong oxidizing property of ozone to decompose organic matter, inorganic matter and microorganisms in the water, thereby improving the water quality. Water treatment ozone generators are widely used in drinking water treatment, sewage treatment, swimming pool water treatment and other fields.

In drinking water treatment, ozone generators can remove odor and color from water, kill bacteria and viruses in water, and improve the safety and taste of drinking water. In sewage treatment, ozone generators can accelerate the decomposition of organic matter in sewage, improve the biodegradability of sewage, and create favorable conditions for subsequent biological treatment. In swimming pool water treatment, ozone generators can inhibit the growth of algae, reduce the use of disinfectants, and protect the health of swimmers.

3. High-quality ozone generator: quality determines efficiency and safety

Whether it is an industrial ozone generator or a water treatment ozone generator, its quality is directly related to the operating efficiency and safety of the equipment. High-quality ozone generators usually use advanced production processes and high-quality materials to ensure that the equipment remains efficient and stable in long-term operation.

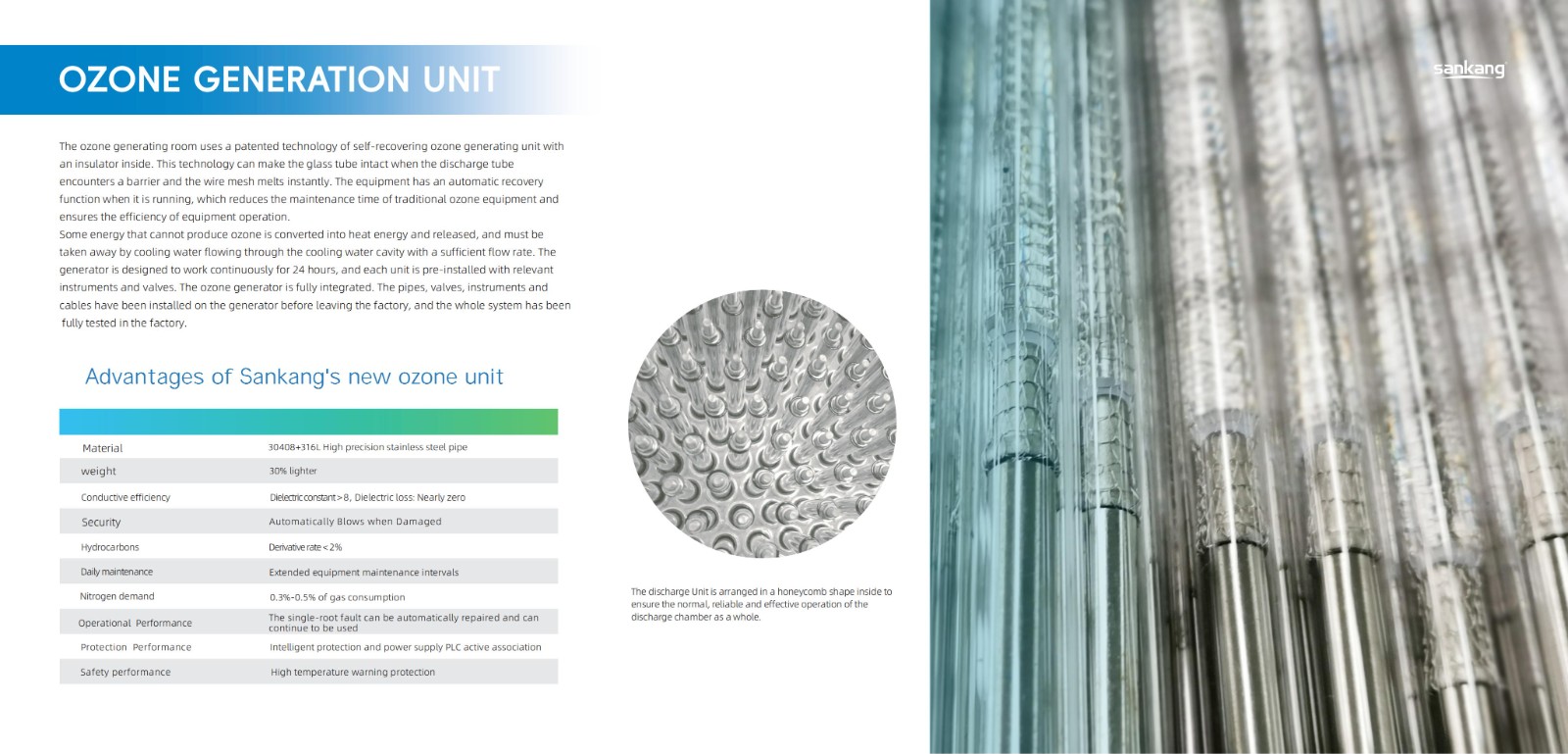

High-quality ozone generators pay more attention to details in design. For example, use high-efficiency ozone generation units to improve the efficiency of ozone generation; optimize the gas distribution system to ensure uniform distribution of ozone; equip with advanced control systems to achieve intelligent management of equipment. These designs not only improve the performance of the ozone generator, but also reduce the energy consumption and operating costs of the equipment.

In addition, high-quality ozone generators also perform well in terms of safety. They are usually equipped with complete safety protection devices, such as overvoltage protection, overcurrent protection, overheating protection, etc., to ensure that the equipment can automatically shut down under abnormal conditions to prevent accidents. At the same time, high-quality ozone generators also focus on environmental protection performance, reduce the discharge of waste gas and wastewater, and reduce the impact on the environment.

IV. Conclusion

Industrial ozone generators, water treatment ozone generators and high-quality ozone generators play an important role in modern industry and environmental protection. They not only improve production efficiency and reduce operating costs, but also promote the development of environmental protection. Choosing high-quality ozone generators is the key to ensuring equipment operating efficiency and safety. In the future, with the advancement of science and technology and the improvement of environmental awareness, ozone generators will be used in more fields and contribute to the sustainable development of mankind.