110KG Ozone Generator

Highly efficient and energy-saving, ozone utilization rate is as high as 95%

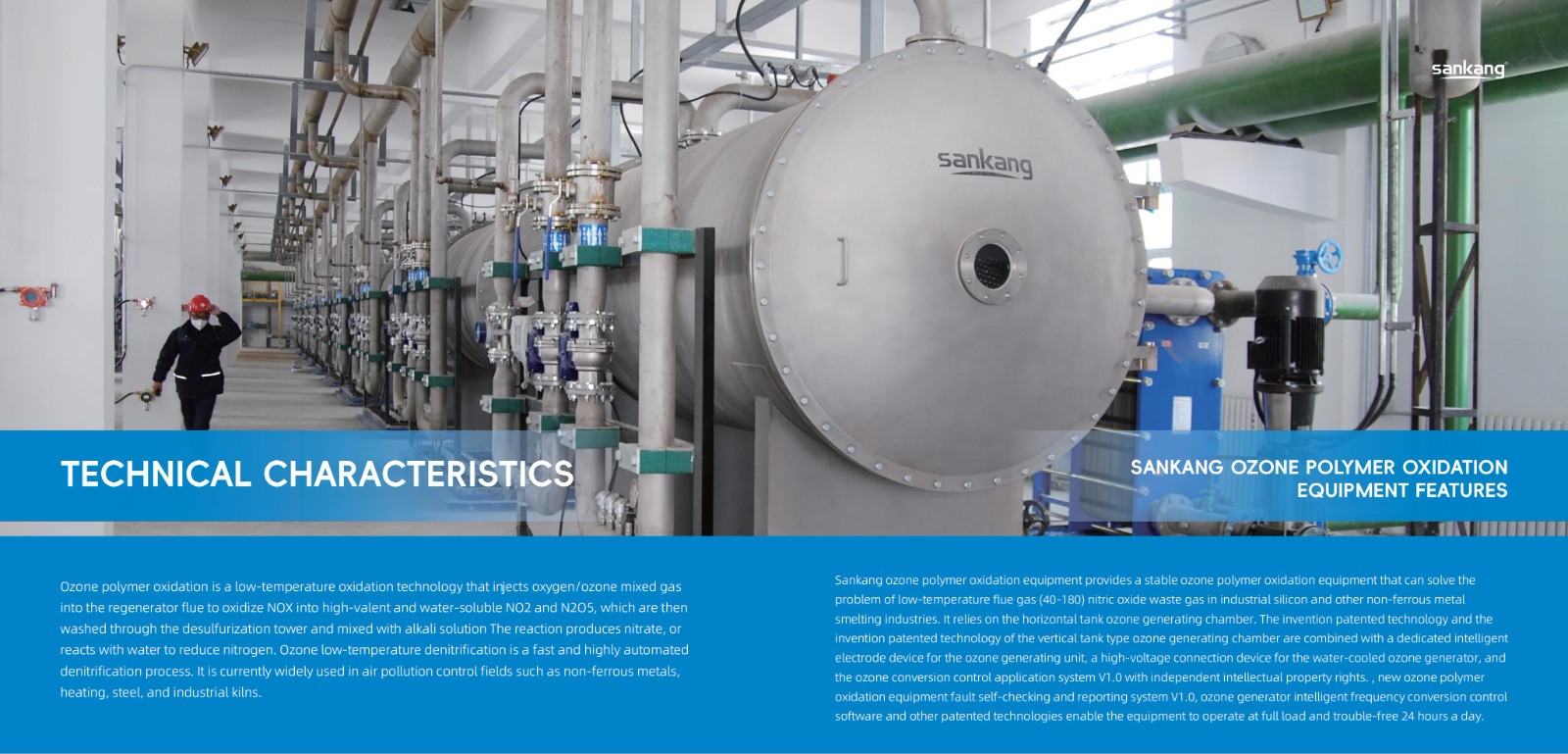

The application of IGBT inverter medium-frequency high-voltage power supply can effectively improve ozone generation efficiency, achieve high efficiency and energy saving, and ensure continuous and stable operation.

The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.

The ozone system uses water cooling technology to maintain efficient and stable ozone production.

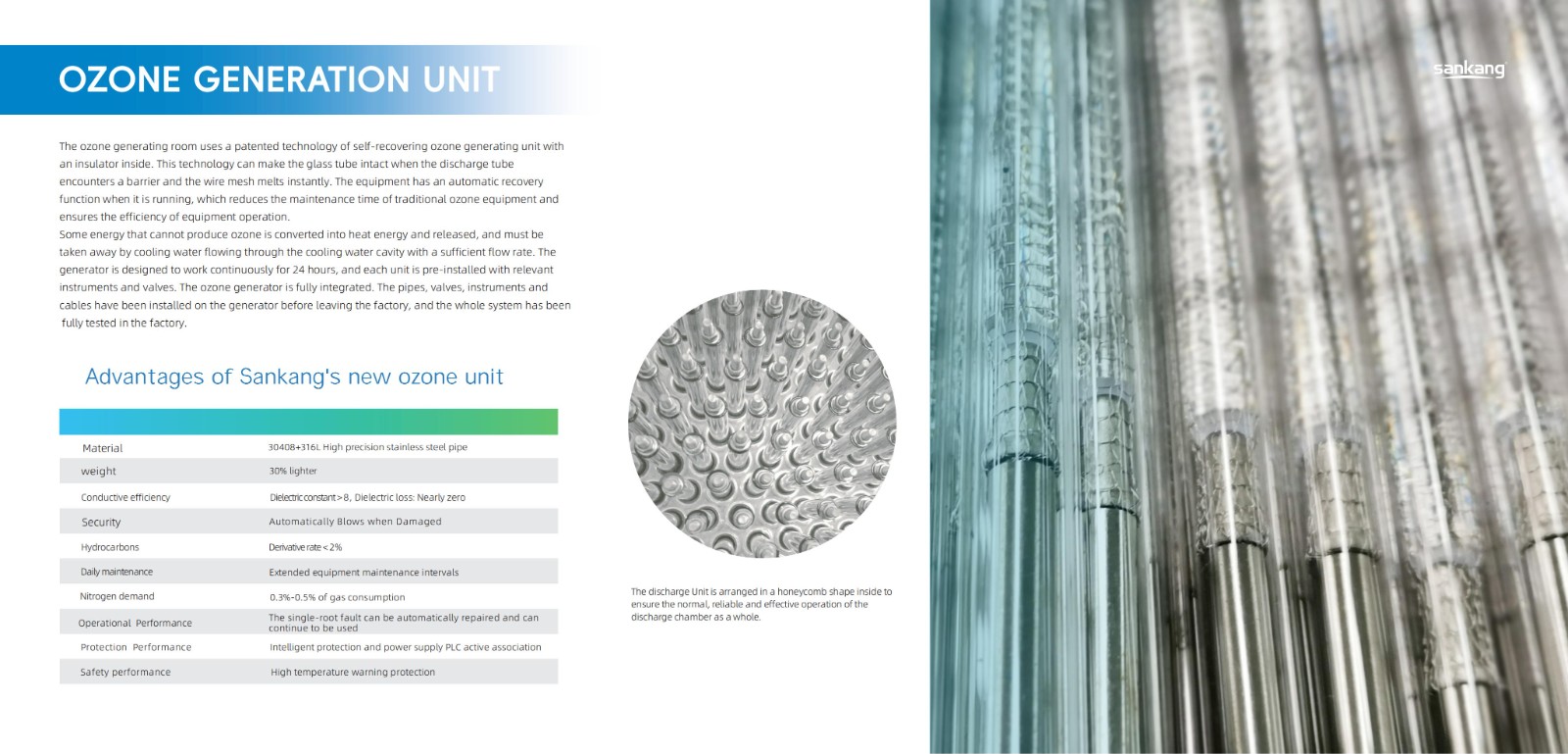

The discharge tube adopts advanced high borosilicate tube discharge technology.

The vacuum thermal regeneration system provides high-quality air to the generating unit and increases the ozone concentration.

The equipment works in negative pressure mode, which effectively avoids ozone leakage and is safe and reliable.

In the field of modern industry and environmental protection, ozone generators, as an efficient and environmentally friendly equipment, play a pivotal role. Among them, the 110KG-level ozone generator has become one of the indispensable equipment in many industries with its powerful ozone production capacity and wide application scenarios. This article will explore in depth the technical characteristics, working principles, application fields, and maintenance of the 110KG ozone generator, in order to provide valuable reference for relevant practitioners.

1. Technical characteristics

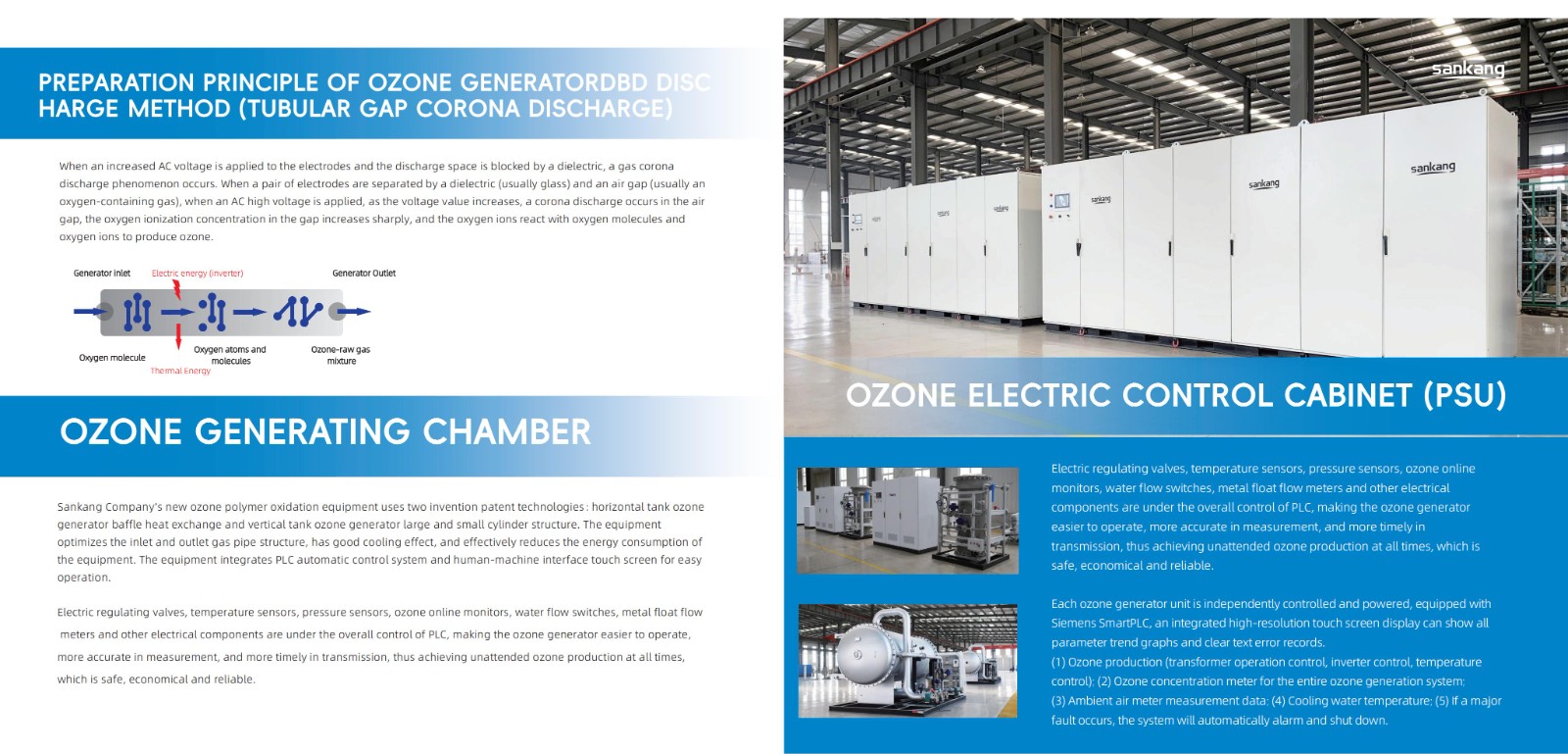

As the name suggests, the 110KG ozone generator has a designed capacity of 110 kilograms of ozone per hour. This capacity enables the equipment to meet the needs of large-scale ozone treatment, whether it is water treatment, air purification, or food processing, medical and health fields, it can play an excellent role. In terms of technology, the 110KG ozone generator usually uses advanced dielectric barrier discharge (DBD) technology or ultraviolet (UV) radiation technology to produce ozone. The dielectric barrier discharge technology ionizes oxygen molecules in the air through a high-frequency high-voltage electric field to form ozone; while the ultraviolet radiation technology uses ultraviolet photons to excite oxygen molecules, decomposing them into atomic oxygen and then combining them into ozone molecules. Both technologies have their own advantages and disadvantages, but both can ensure efficient and stable production of ozone.

2. Working principle

Taking the dielectric barrier discharge technology as an example, the working principle of the 110KG ozone generator is as follows: First, the equipment sends dry, pure air or oxygen into the ozone generating chamber through an air compressor or an oxygen source. In the ozone generating chamber, an electric field is formed between the high-voltage electrode and the grounding electrode. When the electric field strength reaches a certain level, the oxygen molecules in the air are ionized under the action of the electric field to form negatively charged oxygen ions and free electrons. These oxygen ions and free electrons further collide and combine in the electric field to eventually form ozone molecules. Ozone molecules have strong oxidizing properties and can quickly decompose organic matter in water, kill bacteria and viruses, and remove odors.

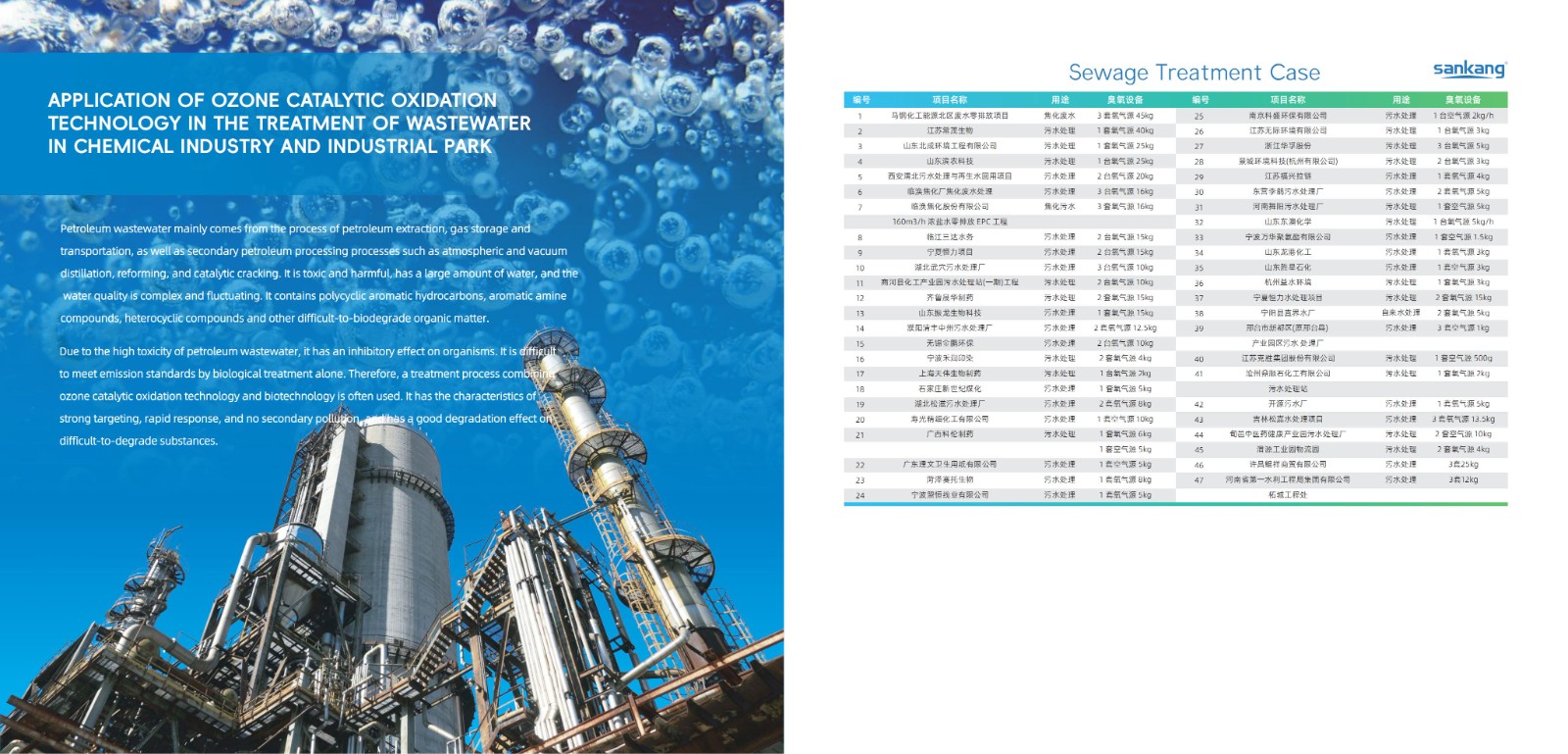

3. Application fields

110KG ozone generators have been widely used in many fields due to their high efficiency and environmental protection. In the field of water treatment, ozone generators are used for disinfection of tap water, swimming pool water, industrial wastewater, etc., which can effectively remove harmful substances in water and improve water quality; in the field of air purification, ozone generators are used to remove harmful gases such as formaldehyde and benzene in indoor air, and kill bacteria and viruses in the air to improve indoor air quality; in the field of food processing, ozone generators are used for food preservation, disinfection of packaging materials, etc., which can extend the shelf life of food and improve food safety; in the field of medical and health care, ozone generators are used for air disinfection in operating rooms, wards, etc., as well as disinfection of medical equipment, providing strong protection for medical safety.

4. Maintenance

In order to ensure the long-term and stable operation of the 110KG ozone generator, regular maintenance is essential. First, the power supply, cables, wiring and other electrical components of the equipment should be checked regularly to ensure that the electrical connection is good and there is no short circuit, open circuit and other phenomena; secondly, the dust, dirt and other impurities in the ozone generating room should be cleaned regularly to avoid affecting the efficiency of ozone generation; in addition, the ozone generation and concentration of the equipment should be tested regularly to ensure that the equipment is always in the best working condition. During the maintenance process, the equipment manual should be strictly followed to avoid equipment damage or safety accidents caused by misoperation.

In summary, as an efficient and environmentally friendly equipment, the 110KG ozone generator plays an important role in many fields. By deeply understanding its technical characteristics, working principles, application fields, maintenance and other aspects, we can make better use of this equipment and contribute to environmental protection, food safety, medical and health care and other undertakings. At the same time, we should continue to explore innovations to promote the continuous progress and development of ozone generator technology.