34KG/h Ozone Generator

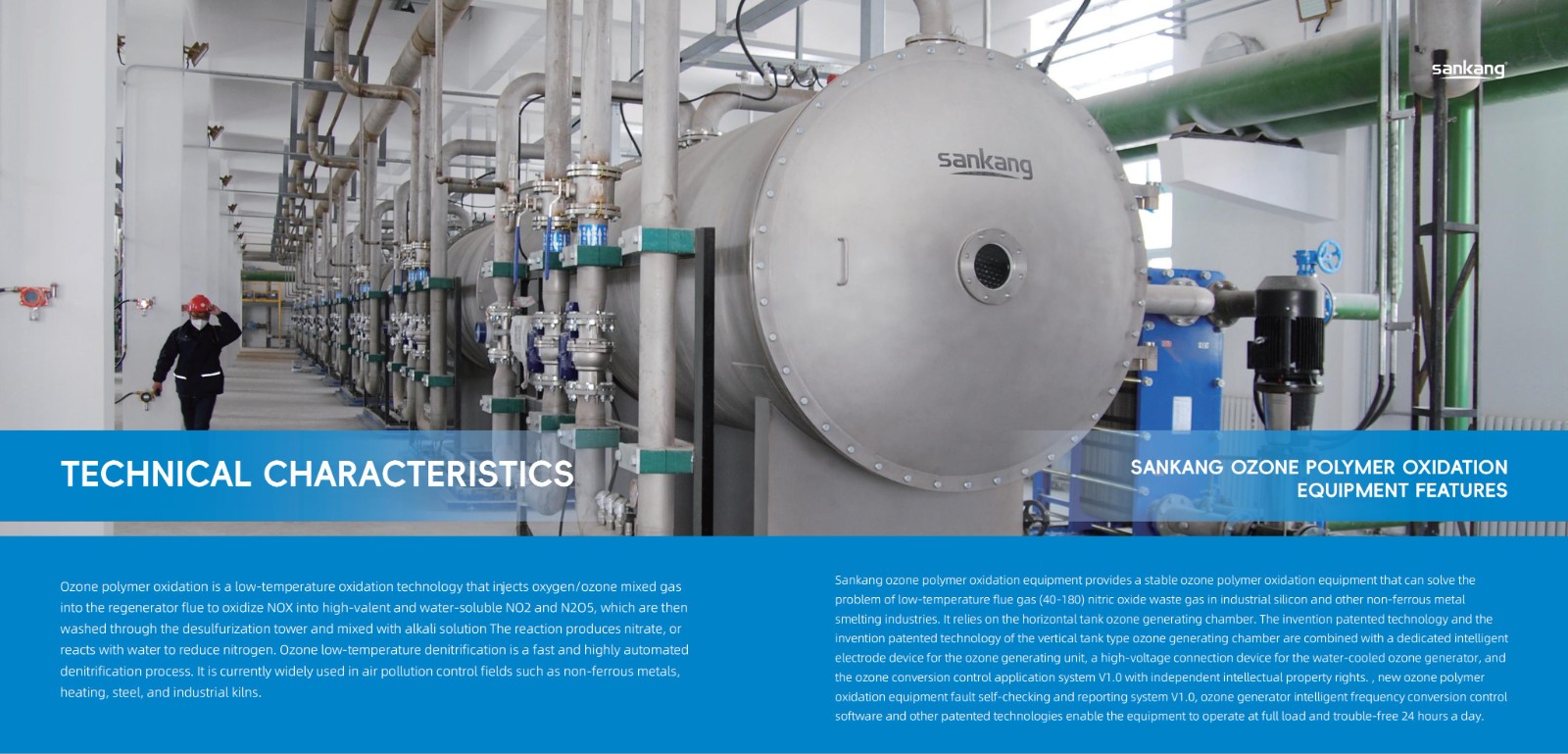

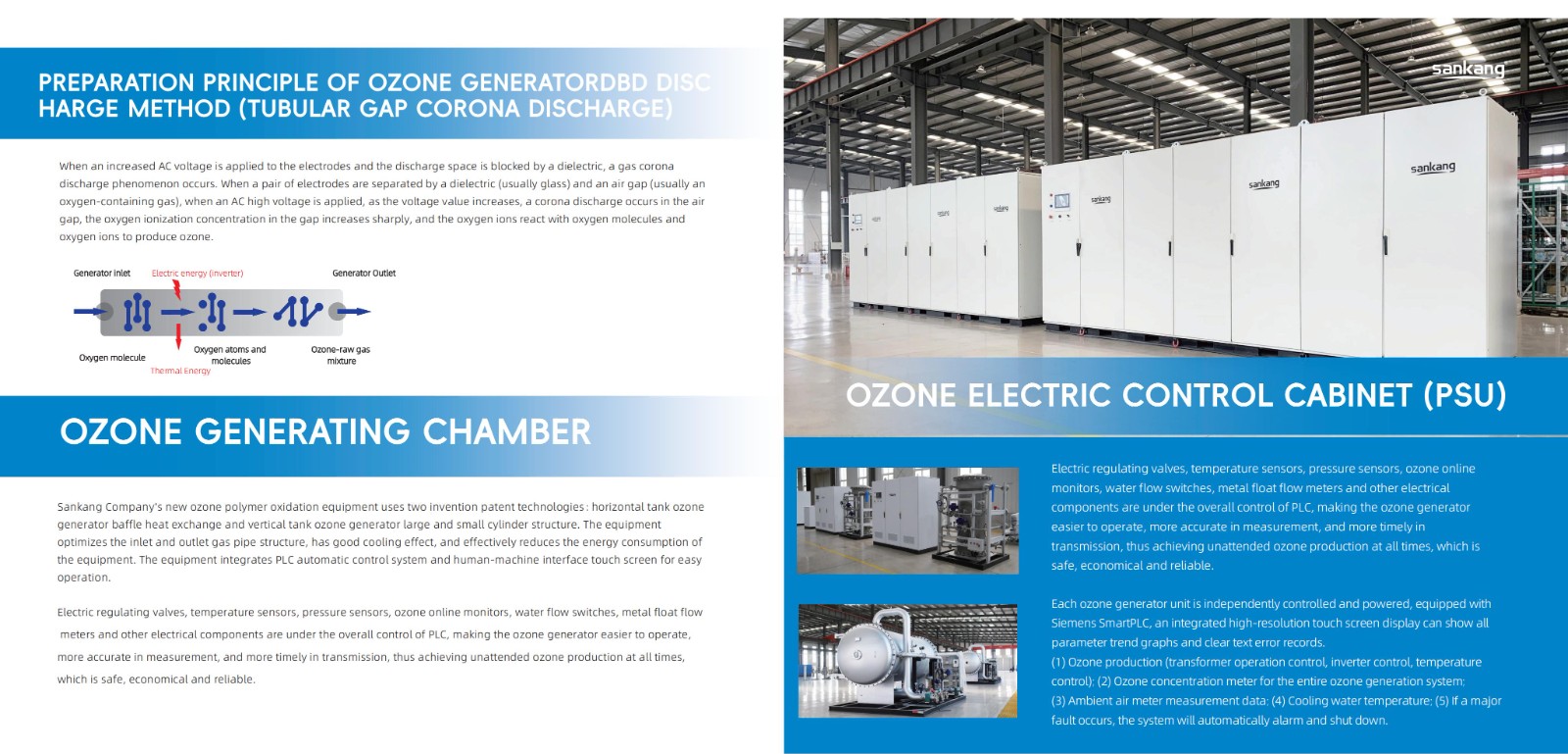

Sankang's new ozone polymer oxidation equipment applies two patented invention technologies: horizontal tank-type ozone generating chamber baffle plate heat exchange and vertical tank-type ozone generating chamber large and small cylinder structure. The equipment optimizes the structure of the air inlet and outlet ducts, has good cooling effect, and effectively reduces the energy consumption of the equipment. The equipment integrates a PLC automatic control system and a human-machine interface touch screen, making it easy to operate.

Electrical control valves, temperature sensors, pressure sensors, ozone online monitors, water flow switches, metal float flowmeters and other electrical components are under the overall control of PLC, making the ozone generator more convenient to operate, more accurate in measurement, and more timely in transmission, realizing ozone The whole production period is unattended, safe, economical and reliable.

34KG/h large ozone generator for industrial wastewater treatment

Today, as environmental protection is increasingly valued, industrial wastewater treatment has become a major issue facing many companies. With the advancement of science and technology, various efficient and environmentally friendly wastewater treatment technologies have emerged. Among them, ozone oxidation technology has been widely used in the field of industrial wastewater treatment due to its strong oxidizing properties and no secondary pollution. This article will introduce in detail the application of a 34KG/h large ozone generator in industrial wastewater treatment, explore its working principle, advantages and actual cases, in order to provide reference for related industries.

1. Working principle of ozone generator

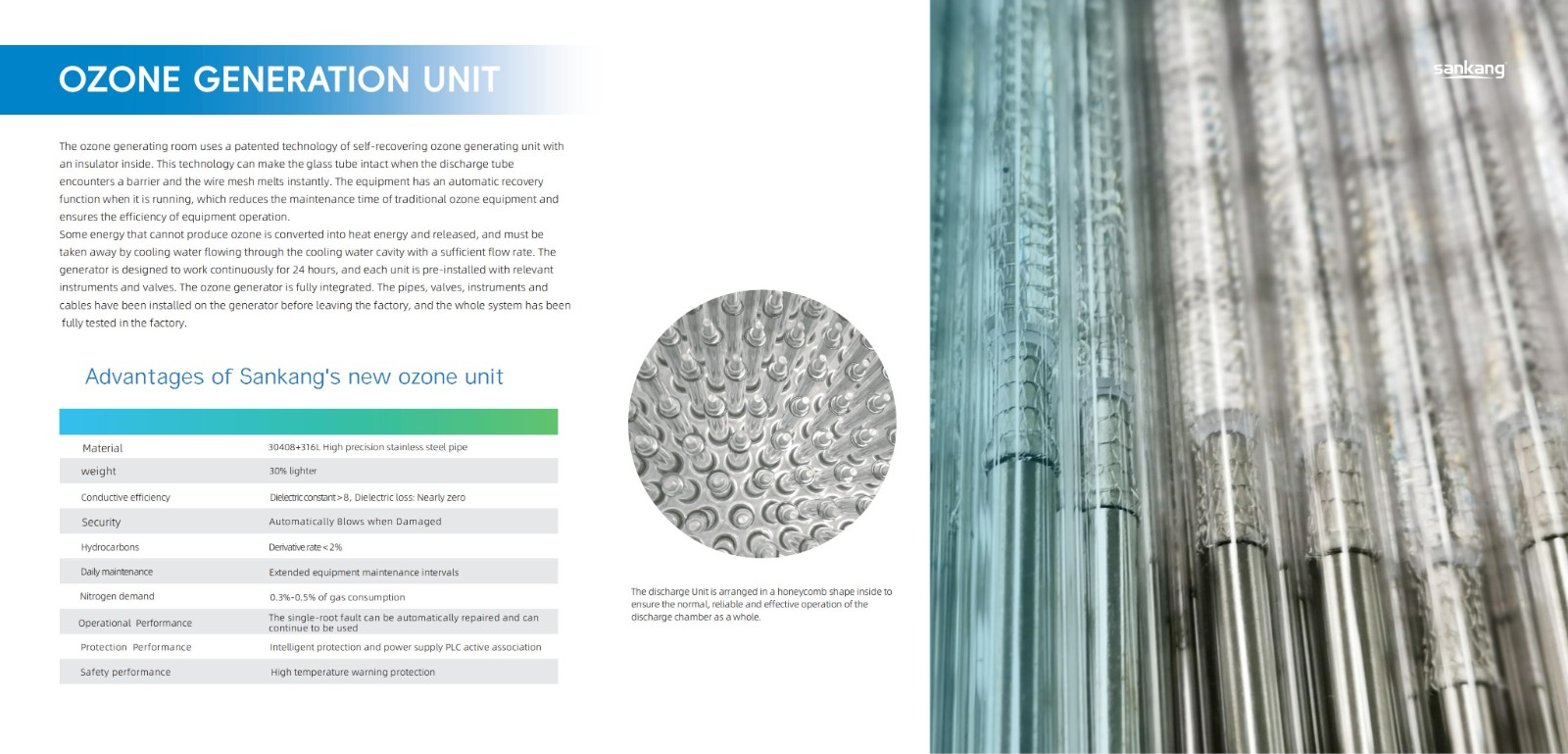

Ozone (O3) is an allotrope of oxygen with extremely strong oxidizing ability. It can quickly decompose organic matter in water, kill bacteria and viruses, remove color and odor, etc. As the name suggests, the 34KG/h large ozone generator is designed to produce 34 kilograms of ozone gas per hour. This equipment usually converts oxygen (O2) in the air into ozone (O3) by high-voltage discharge or ultraviolet irradiation.

Specifically, the high-voltage discharge method is currently the most commonly used method for generating ozone in industry. In this process, dry air or pure oxygen is sent into the ozone generator, and after pretreatment (such as dust removal and dehumidification), it enters the discharge chamber. In the discharge chamber, the high-voltage electric field ionizes the oxygen molecules to form high-energy electrons. These electrons collide with the oxygen molecules, causing the oxygen molecules to decompose into oxygen atoms, which then combine with the undecomposed oxygen molecules to form ozone. The ultraviolet irradiation method uses ultraviolet rays of a specific wavelength to excite oxygen molecules and promote their conversion into ozone.

2. Advantages of 34KG/h large ozone generators in industrial wastewater treatment

1. High-efficiency oxidation capacity: The oxidation potential of ozone is much higher than that of common oxidants such as chlorine and potassium permanganate. It can quickly oxidize and decompose the difficult-to-degrade organic matter in the wastewater, improve the biodegradability of the wastewater, and create favorable conditions for subsequent biological treatment.

2. No secondary pollution: After ozone decomposes in water, the final product is oxygen, which will not introduce new pollutants and is environmentally friendly.

3. Sterilization and disinfection: Ozone can not only effectively remove organic pollutants in wastewater, but also kill bacteria, viruses and other microorganisms in water, and improve the quality of effluent.

4. Strong adaptability: Ozone oxidation technology is suitable for various types of industrial wastewater treatment, including printing and dyeing, pharmaceuticals, chemicals, papermaking and other industries, and has a wide range of applicability.

5. High degree of automation: Modern ozone generators are usually equipped with advanced control systems, which can realize remote monitoring, automatic adjustment of ozone production and other functions, and improve operating efficiency and safety.

III. Practical application case analysis

Take a chemical plant as an example. The plant produces a large amount of wastewater containing high-concentration organic matter during the production process, and traditional treatment methods are difficult to meet the emission standards. After investigation, it was decided to use a 34KG/h large ozone generator for pretreatment. After the project is implemented, the wastewater first passes through pretreatment units such as screens and regulating tanks to remove large particle impurities and adjust the water quality, and then enters the ozone contact reaction tank. Under the action of ozone, the organic matter in the wastewater is effectively decomposed, and COD (chemical oxygen demand) and BOD5 (biochemical oxygen demand for five days) are significantly reduced. After subsequent biological treatment, the effluent quality meets the national emission standards, and the treatment cost is lower than before, achieving a win-win situation of economic and environmental benefits.

IV. Conclusion

As an important equipment for industrial wastewater treatment, the 34KG/h large ozone generator has been widely used in many industries due to its high efficiency, environmental protection and strong adaptability. Through reasonable process design and operation management, ozone oxidation technology can significantly improve the wastewater treatment effect, reduce treatment costs, and contribute to the sustainable development of enterprises and environmental protection. In the future, with the continuous advancement of technology and further reduction of costs, the application prospects of ozone generators in the field of industrial wastewater treatment will be broader.