36KG/h Ozone Generator

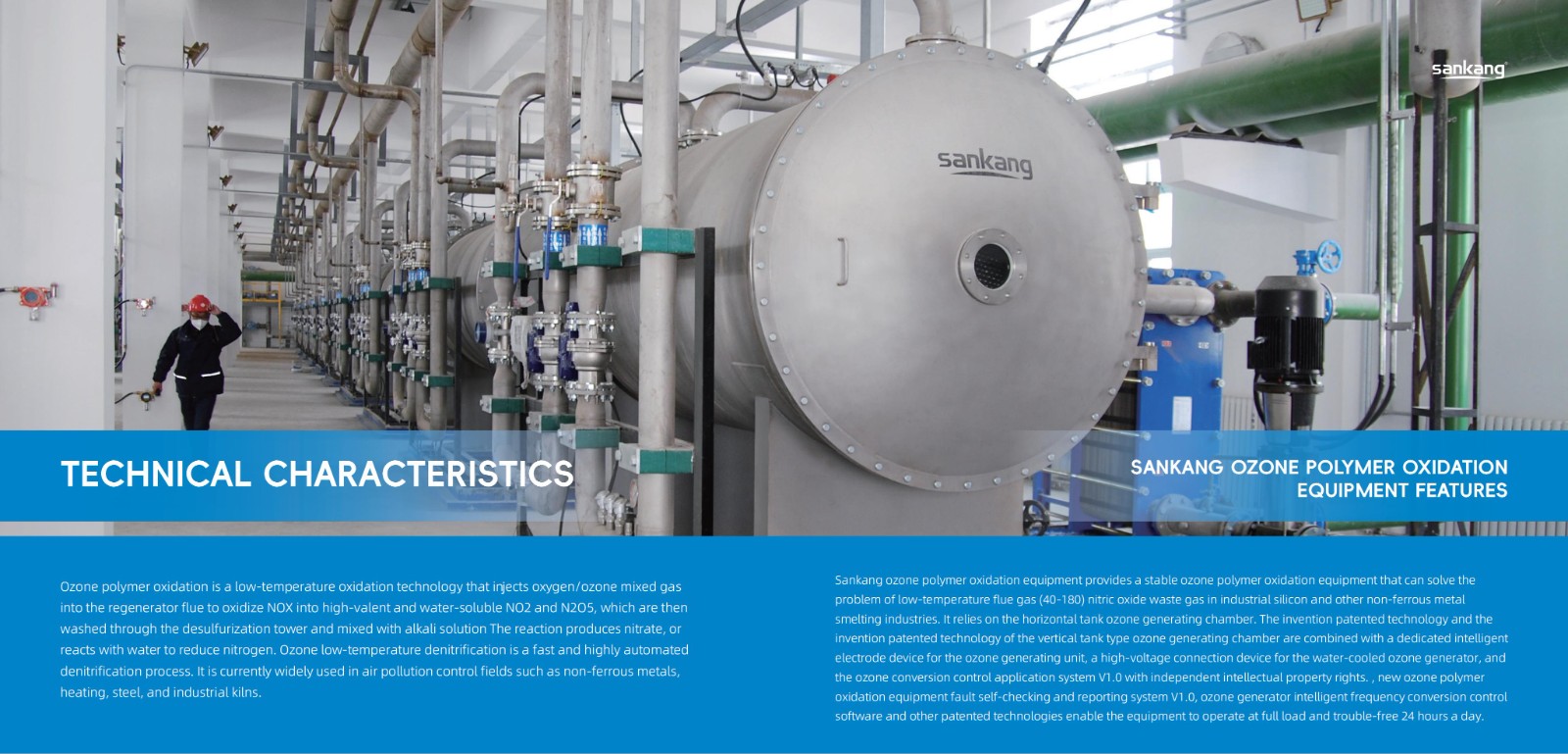

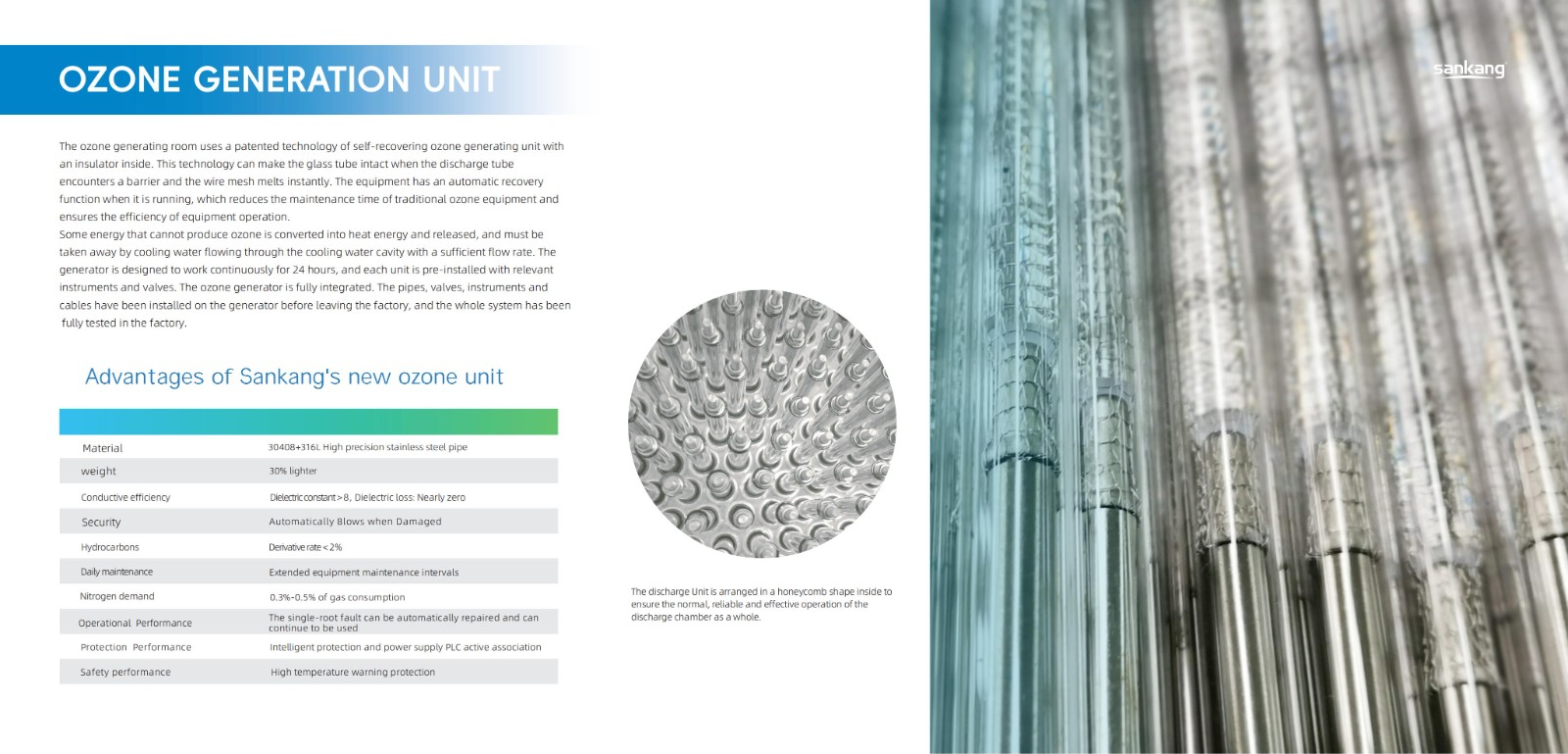

Sankang's new ozone polymer oxidation equipment applies two patented invention technologies: horizontal tank-type ozone generating chamber baffle plate heat exchange and vertical tank-type ozone generating chamber large and small cylinder structure. The equipment optimizes the structure of the air inlet and outlet ducts, has good cooling effect, and effectively reduces the energy consumption of the equipment. The equipment integrates a PLC automatic control system and a human-machine interface touch screen, making it easy to operate.

Electrical control valves, temperature sensors, pressure sensors, ozone online monitors, water flow switches, metal float flowmeters and other electrical components are under the overall control of PLC, making the ozone generator more convenient to operate, more accurate in measurement, and more timely in transmission, realizing ozone The whole production period is unattended, safe, economical and reliable.

36KG/h Large Ozone Generator Water Treatment Ozone Machine

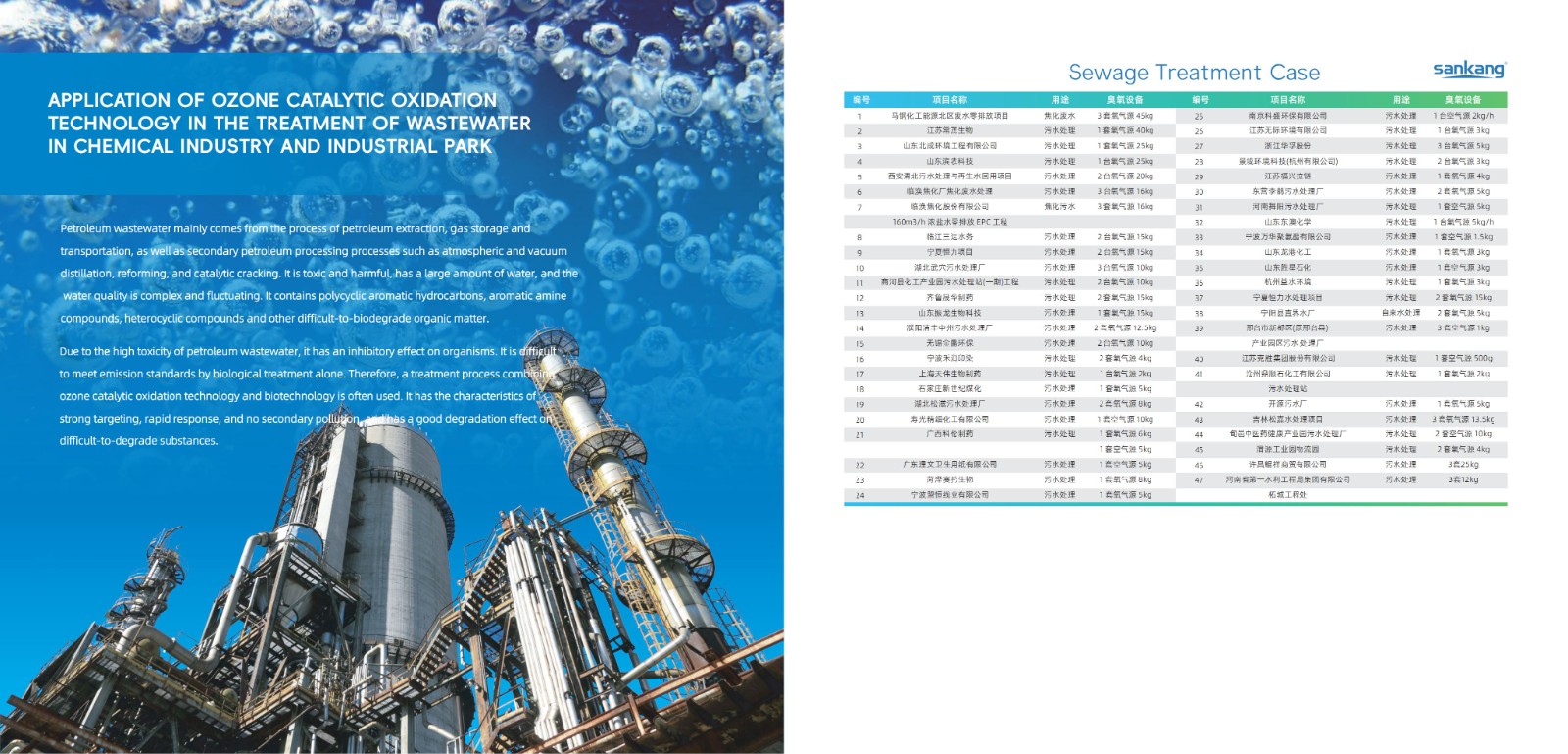

In today's environmental protection and water treatment field, ozone technology has gradually become a leader among many water treatment solutions with its high efficiency, environmental protection, and no secondary pollution. Among this series of ozone application equipment, the 36KG/h large ozone generator water treatment ozone machine has become a star product in large-scale water treatment projects with its powerful ozone generation capacity and wide range of applications. This article will comprehensively analyze this efficient water treatment equipment from the aspects of equipment overview, working principle, performance characteristics, application scenarios and maintenance.

1. Equipment Overview

As the name suggests, the 36KG/h large ozone generator water treatment ozone machine has a designed capacity of 36 kilograms of ozone per hour. This output is sufficient to meet the needs of large-scale industrial water treatment, swimming pool circulating water purification, municipal water supply treatment, aquaculture water quality improvement, etc. The equipment usually adopts advanced ozone generation technology, such as dielectric barrier discharge (DBD) or corona discharge technology, to stimulate oxygen molecules in the air through a high-voltage electric field, so that they are cracked and recombined into ozone molecules (O3), thereby achieving efficient production of ozone.

2. Working principle

The core of the ozone generator lies in its ozone generation unit. When dry, pure oxygen or air passes through a high-voltage electric field, the oxygen molecules are ionized and decomposed into oxygen atoms, which then combine with undecomposed oxygen molecules to form ozone molecules. The whole process requires a stable oxygen supply, precisely controlled electric field strength, and an efficient cooling system to ensure the continuity and efficiency of ozone generation. In addition, to ensure the stability and safety of ozone output, the equipment is also equipped with a precise ozone concentration detection and control system to monitor and adjust the ozone output concentration in real time.

3. Performance characteristics

1. **High-efficiency production capacity**: 36 kg of ozone output per hour, suitable for large-scale water treatment projects, can significantly improve water treatment efficiency.

2. **Energy-saving and environmentally friendly**: It adopts advanced ozone generation technology with low energy consumption, and ozone can be quickly decomposed into oxygen in the natural environment without residual pollution.

3. **Intelligent control**: The integrated control system supports remote monitoring and adjustment, which is convenient for users to adjust the ozone production and concentration according to actual needs.

4. **Safe and reliable**: It is equipped with multiple safety protection devices, such as overvoltage protection, overcurrent protection, overheating protection, etc., to ensure the safe operation of the equipment.

5. **Easy maintenance**: Modular design, easy maintenance and replacement of parts, reducing maintenance costs and downtime.