90kg Ozone Generator

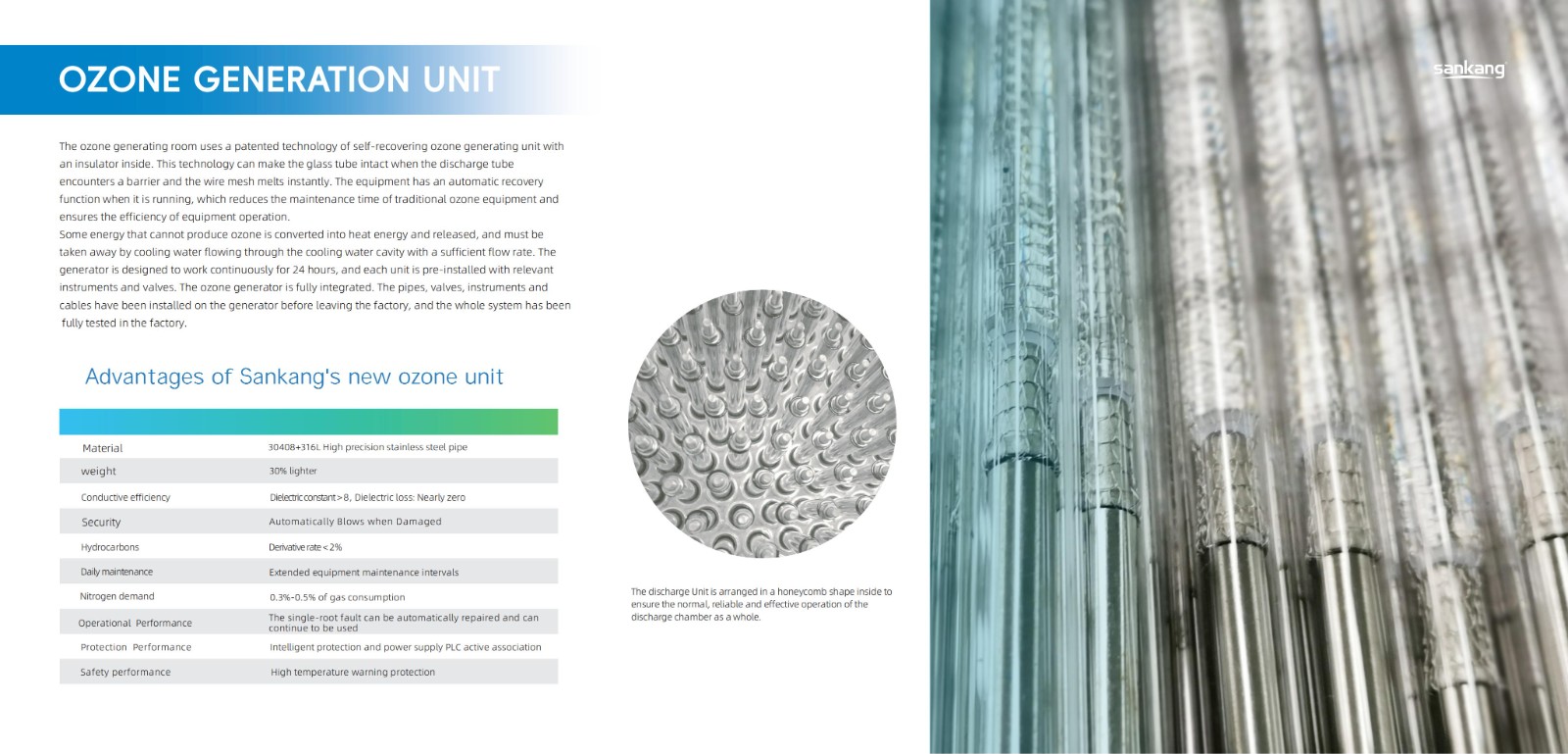

The power supply part adopts a modular design, and the equipment discharge unit has high efficiency and easy maintenance.

The ozone system uses water cooling technology to maintain efficient and stable ozone production.

The discharge tube adopts advanced high borosilicate tube discharge technology.

The vacuum thermal regeneration system provides high-quality air to the generating unit and increases the ozone concentration.

The equipment works in negative pressure mode, which effectively avoids ozone leakage and is safe and reliable.

In today's environmental protection and water treatment fields, ozone generators, as efficient and pollution-free disinfection equipment, have received widespread attention and application. In recent years, China has made remarkable progress in the field of ozone generator manufacturing, especially in large-scale ozone generator technology, which has reached the international advanced level. This article will introduce in detail a 90KG/h ozone generator made in China, demonstrating its latest technology and application advantages.

1. The basic working principle of ozone generator

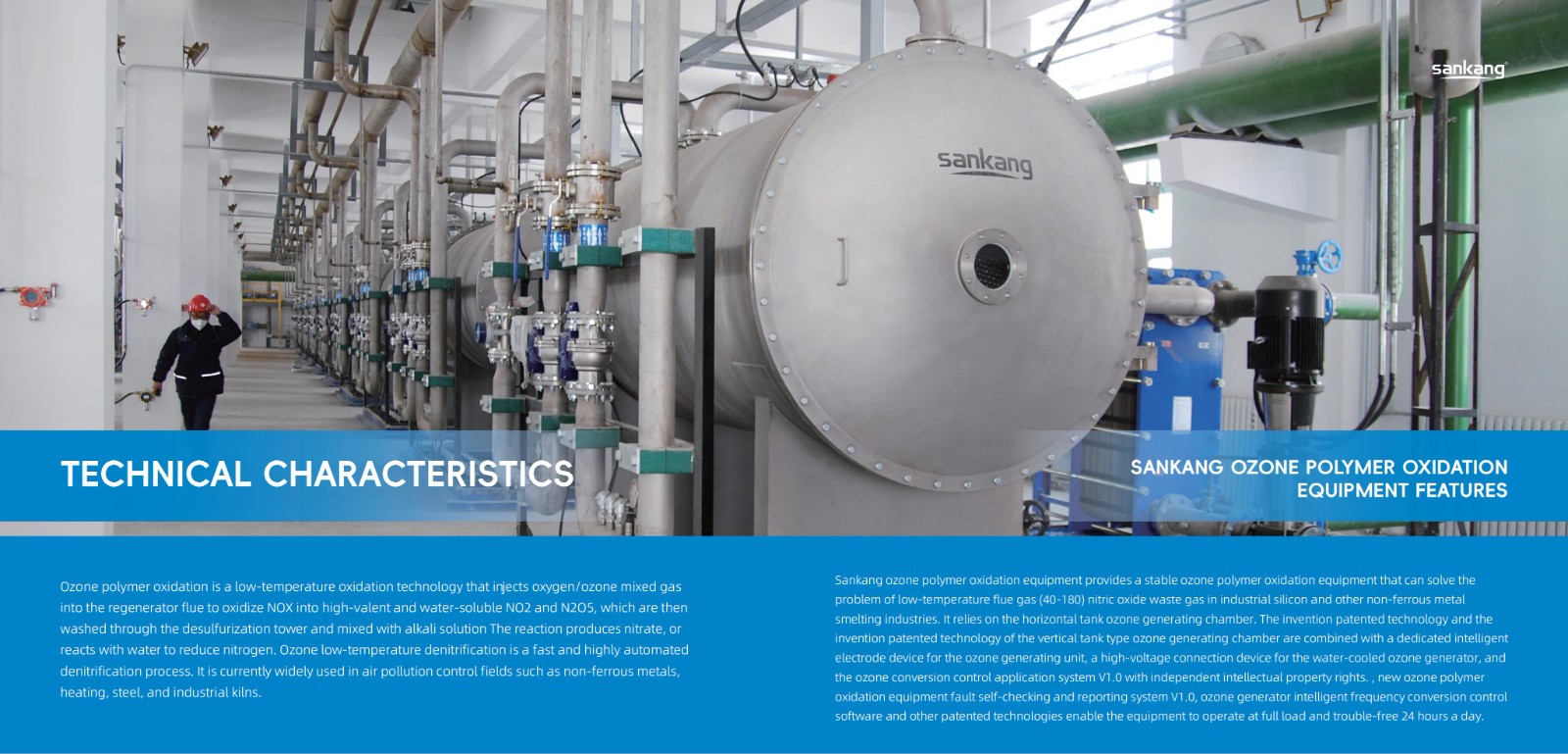

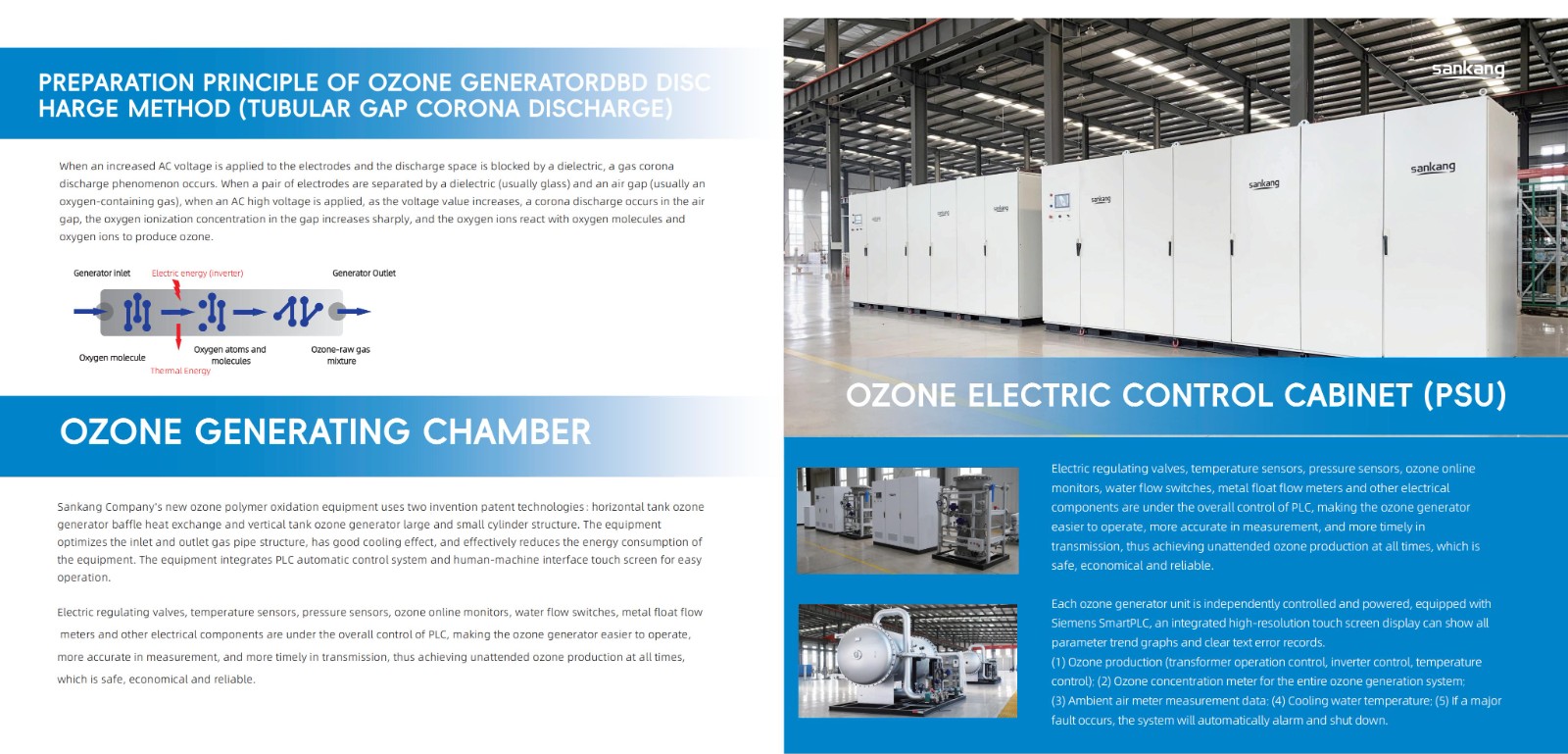

The working principle of the ozone generator is based on the preparation of ozone, that is, bombarding oxygen molecules with high-speed electron flow to dissociate them into oxygen atoms, which then quickly react with oxygen molecules to form ozone molecules. This process is completed in the ozone generating chamber, so the ozone generator is usually composed of an ozone generating chamber, a power supply system, a control system, a gas source system, a cooling system, a dosing system and an exhaust gas destruction system.

2. Technical features of 90KG/h ozone generator

1. **Efficient and stable ozone production**

This 90KG/h ozone generator adopts advanced micro-gap discharge technology, which effectively improves the efficiency of ozone generation. At the same time, its modular design makes the installation, inspection and maintenance of the equipment easier. By optimizing the power supply system and control system, the stability and efficiency of ozone production are ensured.

2. **Optimized cooling system**

Ozone is extremely sensitive to temperature; the higher the temperature, the faster it decomposes. Therefore, an efficient cooling system is essential for the ozone generator. This equipment adopts a closed-loop internal circulation cooling system, which can effectively prevent the corrosion of stainless steel pipes inside the ozone generator due to changes in the external circulation water quality, while ensuring the stability and reliability of the equipment during long-term operation.

3. **Advanced air supply system**

The gas source system is one of the key factors affecting the performance of the ozone generator. This device provides two options: oxygen source and air source to meet the needs of different application scenarios. For scenes with high ozone concentration demand, an oxygen source should be used. Two options are available: on-site production of oxygen using oxygen generators or liquid oxygen gasification.

4. **Intelligent control system**

The control system is the core of the entire ozone preparation system. It collects the working parameters of the ozone generator in real time, monitors the operating status, and displays it to the user through the HMI human-machine interface. When the system malfunctions, local or remote alarms are promptly sent to users. The control system of this equipment adopts advanced intelligent technology and can provide customized solutions according to user needs to meet the requirements of various scenarios.

3. Application fields of 90KG/h ozone generator

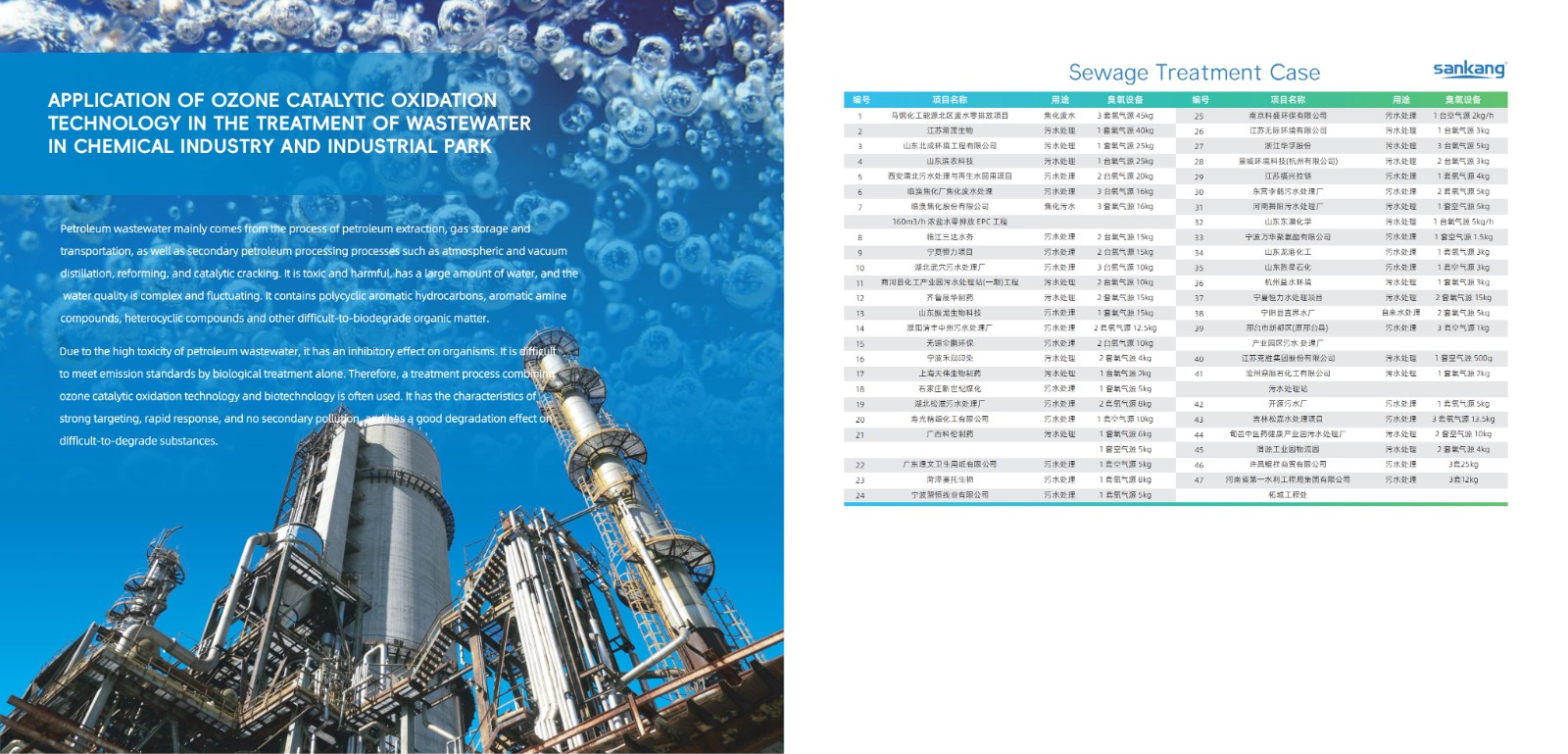

1. Water treatment

Ozone has a high killing rate and fast speed for bacteria, viruses and other microorganisms in water, and can completely remove pollutants such as organic compounds without causing secondary pollution. This 90KG/h ozone generator is widely used in urban sewage treatment, urban drinking water treatment, bottled water industrial wastewater treatment and other fields.

2. **Chemical Oxidation Synthesis**

Ozone is used as an oxidant, catalyst and refining agent in the chemical, petroleum, paper, textile, pharmaceutical and fragrance industries. Its strong oxidizing ability can easily break the carbon chain bonds of olefins and alkynes, causing them to be partially oxidized and then synthesized into new compounds.

3. **Pulp bleaching**

Ozone is used in the pulp and paper industry for chemical pulp bleaching or to improve the mechanical properties of mechanical pulp, helping to reduce chlorine pollution to the environment during pulp bleaching.

4. Advantages of ozone generators made in China

In recent years, China has made remarkable progress in the field of ozone generator manufacturing. Compared with existing domestic large-scale machines, the large-scale ozone generators made in China have the characteristics of compact structure, small footprint, stable operation, safety and reliability, lower energy consumption and more stable performance. At the same time, the Chinese manufacturer also provides comprehensive after-sales service and technical support to ensure the long-term stable operation of the equipment.

V. Conclusion

With the continuous improvement of environmental awareness and the continuous development of water treatment technology, ozone generators will be used in more fields. The 90KG/h ozone generator manufactured in China has demonstrated its excellent performance and broad application prospects in many fields with its efficient and stable ozone production, optimized cooling system, advanced air source system and intelligent control system. In the future, Chinese manufacturers will continue to focus on technological innovation and product quality improvement, and provide global users with better-quality and more efficient ozone generator products and services.